Introduction to Air Blown Micro Cables Technology

Air blown micro cables represent a groundbreaking advancement in fiber optic installation techniques. Unlike traditional fiber cables that require manual pulling through ducts, these innovative micro cables are installed using compressed air, dramatically reducing deployment time and labor costs. This installation method, known as jetting or blowing fiber, is becoming the preferred choice for telecom operators and network installers seeking efficient, future-proof solutions.

The technology behind micro duct fiber optic systems enables network providers to deploy fiber networks faster than ever before while maintaining the flexibility to upgrade capacity as demand grows. With the global push for 5G backhaul solutions and FTTH (Fiber to the Home) expansion, air blown micro cables offer a scalable, cost-effective approach to meet these infrastructure demands.

How Air Blown Micro Cable Systems Work

The air blown micro cable installation process involves three main components working in harmony:

- Microducts: Small, flexible tubes (typically 3mm-16mm in diameter) installed in advance

- Micro cables: Ultra-lightweight fiber optic cables designed specifically for blowing

- Blowing equipment: Specialized machines that propel cables through ducts using compressed air

The installation begins with the placement of microducts, which can be installed in various environments including underground, aerial, or within buildings. Once the duct pathway is established, fiber optic micro cables are blown through the ducts using a combination of compressed air and mechanical force. This method allows for installation speeds of up to 150 meters per minute, significantly faster than traditional pulling methods.

One of the key advantages of this system is the ability to install high fiber count cables over long distances without intermediate splicing points. The reduced friction during installation means cables can be blown up to 2 kilometers in a single run, minimizing potential failure points in the network.

Benefits of Air Blown Fiber Systems

Air blown micro cable technology offers numerous advantages over conventional fiber installation methods:

| Feature | Traditional Fiber | Air Blown Micro Cable |

|---|---|---|

| Installation Speed | Slow (manual pulling) | Fast (up to 150m/min) |

| Labor Requirements | High (multiple crew members) | Low (minimal crew) |

| Upgrade Flexibility | Limited (requires new installation) | Easy (cables can be replaced) |

| Installation Distance | Limited by pulling tension | Up to 2km in one run |

| Future-Proofing | Fixed capacity | Scalable capacity |

| Network Reliability | Potential damage during pulling | Gentler on fibers |

Beyond the advantages shown in the comparison table, air blown micro cables provide additional benefits for specific applications. For data center interconnect projects, the reduced bend radius of micro cables allows for easier routing in congested spaces. In MDU (Multi-Dwelling Unit) installations, the small size of microducts enables discreet deployment without significant aesthetic impact.

The technology also shines in last mile fiber deployment scenarios, where the ability to quickly install and upgrade fibers helps service providers keep pace with growing bandwidth demands. For municipal broadband networks, the reduced installation time translates to faster community-wide connectivity.

Key Applications of Microduct Fiber Systems

Air blown micro cable technology finds application across various sectors of the telecommunications industry:

1. FTTH (Fiber to the Home) Deployments

The flexibility and speed of micro cable installation make it ideal for mass FTTH rollouts. Providers can install the microduct infrastructure in advance and blow in fibers as subscribers sign up, reducing upfront capital expenditure. The small diameter of microducts (as small as 3mm) allows for minimally invasive installation in existing buildings.

2. 5G Network Backhaul

As 5G small cell deployment accelerates, the need for flexible, high-capacity backhaul solutions grows. Air blown micro cables enable rapid connection of small cells to the core network, with the ability to easily upgrade fiber counts as bandwidth requirements increase. The technology supports low latency fiber networks critical for 5G applications.

3. Data Center Interconnects

Modern cloud computing infrastructure requires dense, flexible fiber connections between and within data centers. Microduct systems allow for high-density fiber routing in limited space, with the ability to add or replace cables as needed without major infrastructure changes. This supports the evolving needs of hyperscale data centers.

4. Enterprise Network Upgrades

Business campuses and office buildings benefit from microduct systems when upgrading to 10G or 40G Ethernet networks. The technology enables future-proof installations where additional fibers can be added as bandwidth needs grow, without the cost of completely new infrastructure.

Choosing the Right Air Blown Micro Cable Solution

Selecting the appropriate micro cable system requires consideration of several factors:

Fiber Count Requirements

Micro cables are available in various fiber counts, from single fibers up to 288 fibers or more. For future-proof fiber networks, it's often advisable to install microducts with spare capacity to accommodate future upgrades without additional construction.

Installation Environment

Different environments require specific cable characteristics:

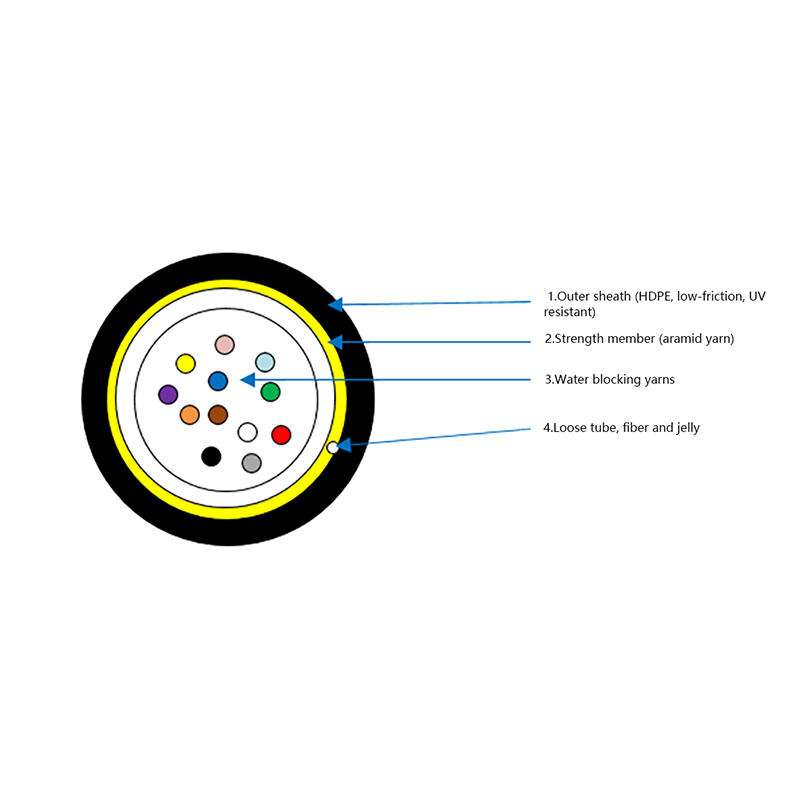

- Outdoor installations: UV-resistant, water-blocking cables

- Aerial deployments: Lightweight cables with high tensile strength

- Indoor installations: Riser or plenum-rated cables for fire safety

- Direct buried applications: Armored micro cables for rodent protection

Blowing Performance

Key factors affecting blowing performance include:

- Cable diameter relative to duct size (typically 60-70% fill ratio)

- Cable surface friction coefficient

- Weight and stiffness characteristics

- Presence of lubricants or special coatings

For optimal results, consult with micro cable installation specialists who can recommend the best combination of ducts, cables, and equipment for your specific project requirements.

Installation Best Practices for Maximum Performance

Proper installation techniques are crucial for achieving the full benefits of air blown micro cable systems:

Duct Network Design

A well-designed microduct network should:

- Minimize bends (maintain bend radius > 10x duct diameter)

- Limit the number of direction changes

- Include access points for future maintenance

- Consider future expansion with spare ducts

Blowing Equipment Setup

Proper equipment configuration ensures successful installations:

- Use appropriate air pressure (typically 10-15 bar)

- Maintain clean, dry air supply to prevent contamination

- Ensure proper cable feeding tension

- Monitor installation speed and force continuously

Cable Handling Procedures

Micro cables require careful handling:

- Store cables on reels in controlled environments

- Avoid kinking or crushing during handling

- Use proper cable straightening techniques before installation

- Protect cable ends from contamination

Following these fiber optic installation guidelines helps ensure reliable, high-performance networks with minimal future maintenance requirements.

Future Trends in Micro Cable Technology

The air blown micro cable market continues to evolve with several emerging trends:

Higher Fiber Density

Manufacturers are developing ultra-high count micro cables with reduced diameters, enabling more fibers in the same duct space. New fiber designs like 200µm fibers (compared to standard 250µm) allow for greater density without compromising performance.

Intelligent Duct Systems

Next-generation systems incorporate smart duct technology with RFID tags or other markers to simplify network documentation and maintenance. Some systems include sensors to monitor duct conditions and cable performance in real-time.

Automated Installation Equipment

Advances in fiber blowing machines include automated tension control, self-adjusting air pressure, and remote monitoring capabilities. These improvements make installations more consistent and reduce the need for highly skilled operators.

Sustainable Solutions

The industry is developing eco-friendly micro cables with reduced material usage and recyclable components. Some manufacturers offer cables with bio-based jackets or reduced hazardous substances.

These innovations promise to further enhance the value proposition of air blown micro cable systems, solidifying their position as the preferred choice for next-gen fiber networks.

Conclusion: Why Air Blown Micro Cables Are Revolutionizing Fiber Optics

Air blown micro cable technology represents a significant leap forward in fiber optic network deployment. By combining faster installation, lower costs, and unparalleled flexibility, these systems address the critical challenges facing network operators today. Whether for 5G mobile infrastructure, FTTH projects, or enterprise network upgrades, microduct systems offer a future-proof solution that can adapt to evolving bandwidth demands.

The ability to quickly deploy and later upgrade fiber capacity without major construction makes air blown micro cables particularly valuable in today's rapidly changing technological landscape. As bandwidth requirements continue to grow with emerging technologies like IoT (Internet of Things), 8K video streaming, and cloud gaming, the scalability of microduct systems will become increasingly important.

For network planners and installers, adopting air blown micro cable technology means delivering projects faster, at lower cost, and with greater long-term value. As the technology continues to evolve with higher density cables and smarter installation methods, its role in building the fiber networks of tomorrow will only expand.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体