How Resistant Are Air Blown Micro Cables to Temperature Fluctuations?

Air blown micro cables (ABMCs) have emerged as a revolutionary solution in modern fiber optic networks. They offer flexibility, scalability, and cost-effectiveness in deployment, particularly in urban environments where space is limited. However, a critical concern for engineers, network planners, and operators is how these cables perform under temperature variations. Understanding the thermal resilience of air blown micro cables is essential for ensuring long-term network reliability and avoiding costly failures.

1. Understanding Air Blown Micro Cables

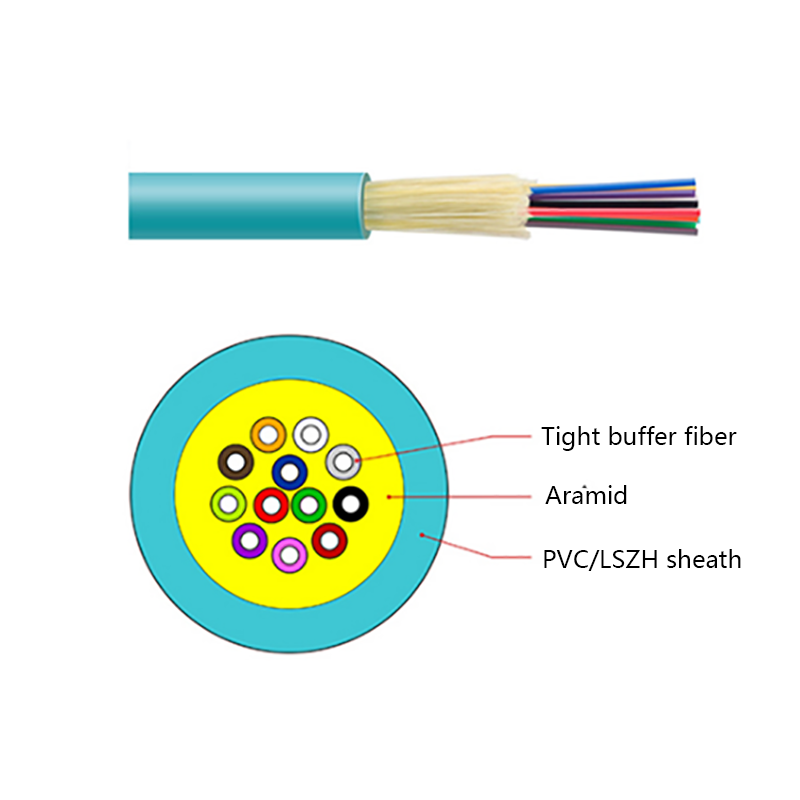

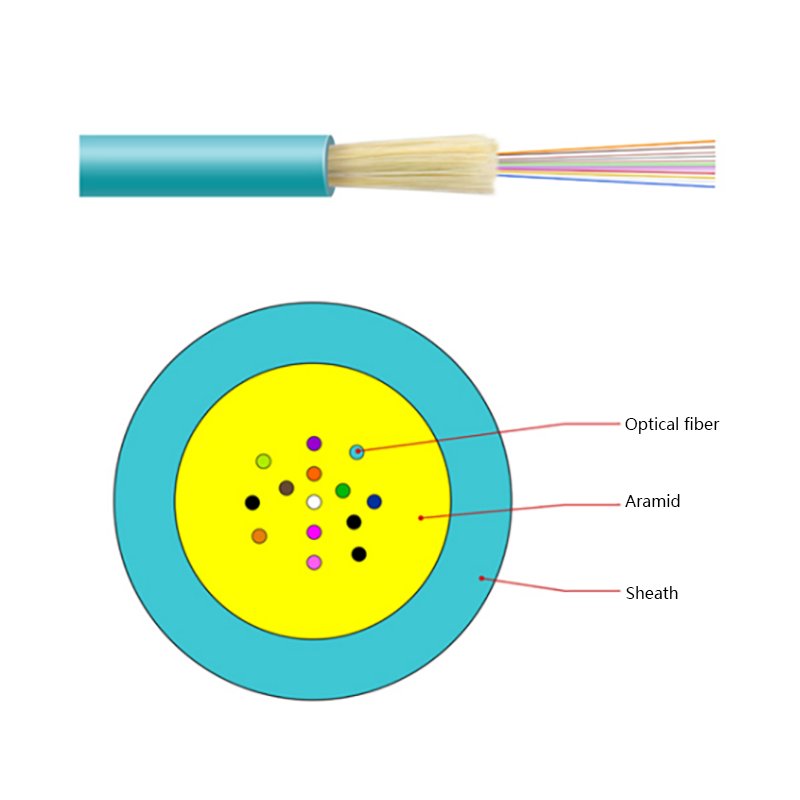

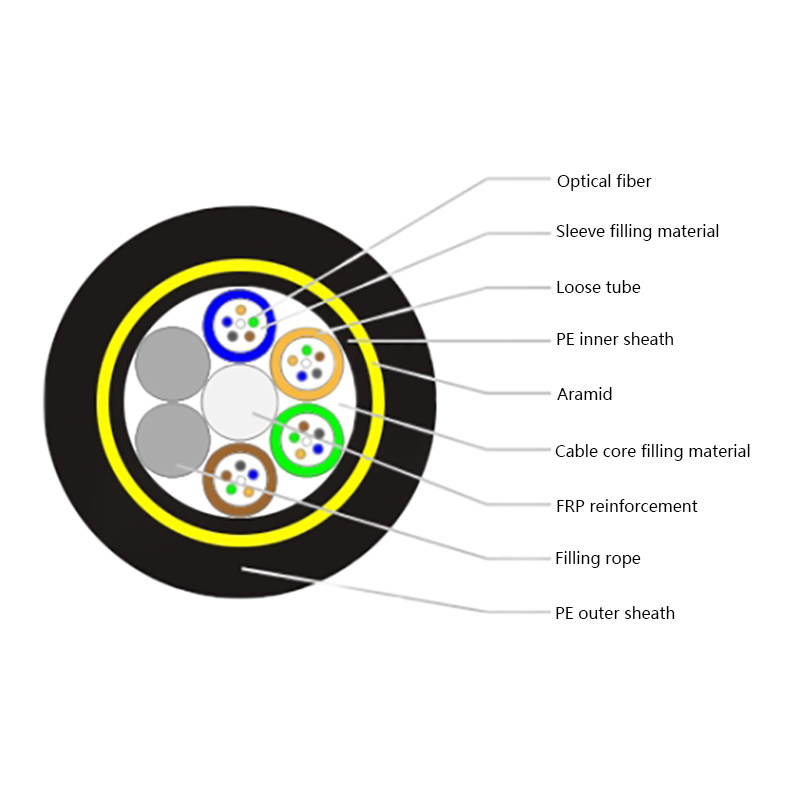

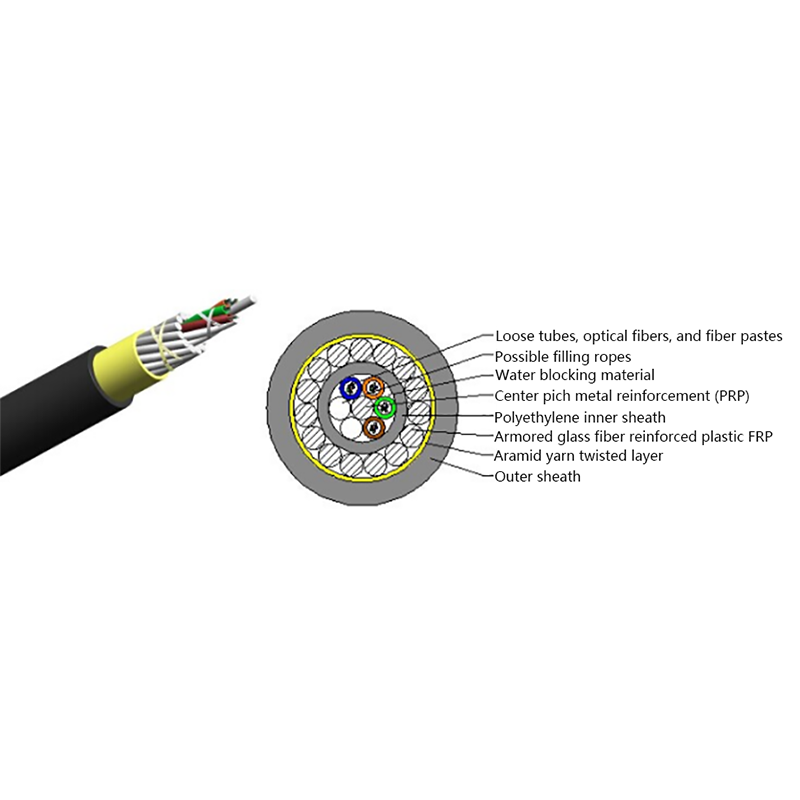

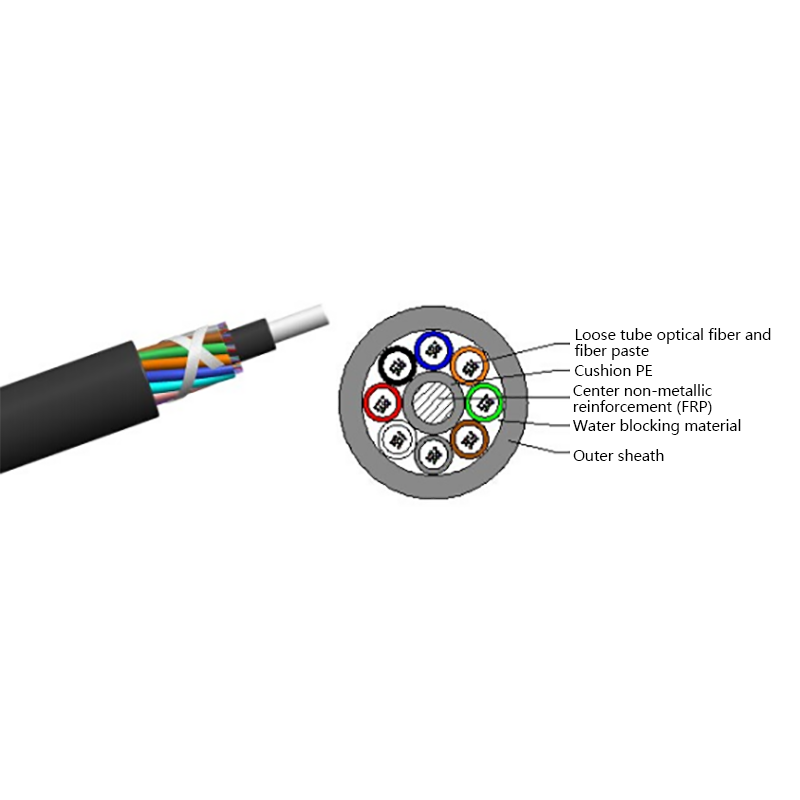

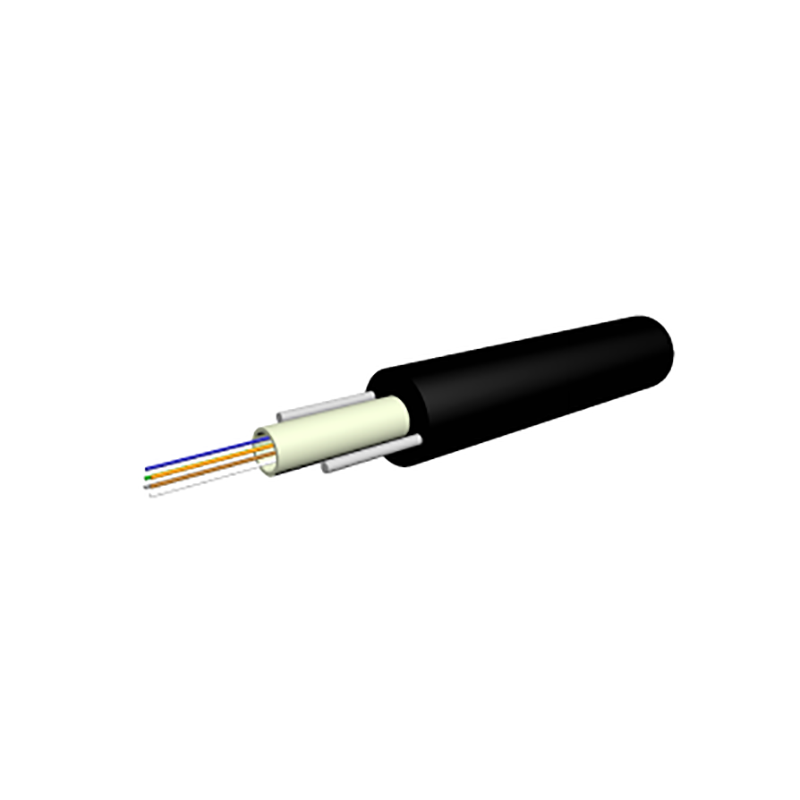

Air blown micro cables are a type of fiber optic cable designed to carry optical fibers inside a hollow microduct. Unlike conventional fiber cables, where fibers are embedded directly within a protective jacket, ABMCs use a blown fiber installation system, allowing fibers to be inserted or replaced without removing the cable itself. Key advantages include:

- Minimal disruption during network upgrades

- High fiber density in small ducts

- Ease of future expansion without extensive digging or installation work

Given these benefits, ABMCs are increasingly deployed in telecommunications, data centers, and FTTH (Fiber to the Home) projects. However, their small size and lightweight design mean that thermal stresses can affect their performance differently than conventional fiber cables.

2. How Temperature Affects Fiber Optic Cables

Temperature fluctuations can impact fiber optic cables in multiple ways:

-

Material Expansion and Contraction:

All cable materials expand and contract when temperatures change. For fiber cables, this includes the jacket, buffer tubes, and fibers themselves. Excessive expansion or contraction may lead to microbending, which can increase signal attenuation. -

Mechanical Stress:

Rapid temperature changes may cause stress between the cable’s layers. In rigid or poorly designed cables, this stress can lead to cracking or deformation. -

Signal Performance:

Fiber optics are sensitive to bending and stress. Temperature-induced contraction of the cable jacket may slightly bend fibers, resulting in increased insertion loss. -

Installation Challenges:

Extremely low temperatures can make micro cables stiff and harder to blow through ducts, while very high temperatures can make them soft, leading to potential damage during installation.

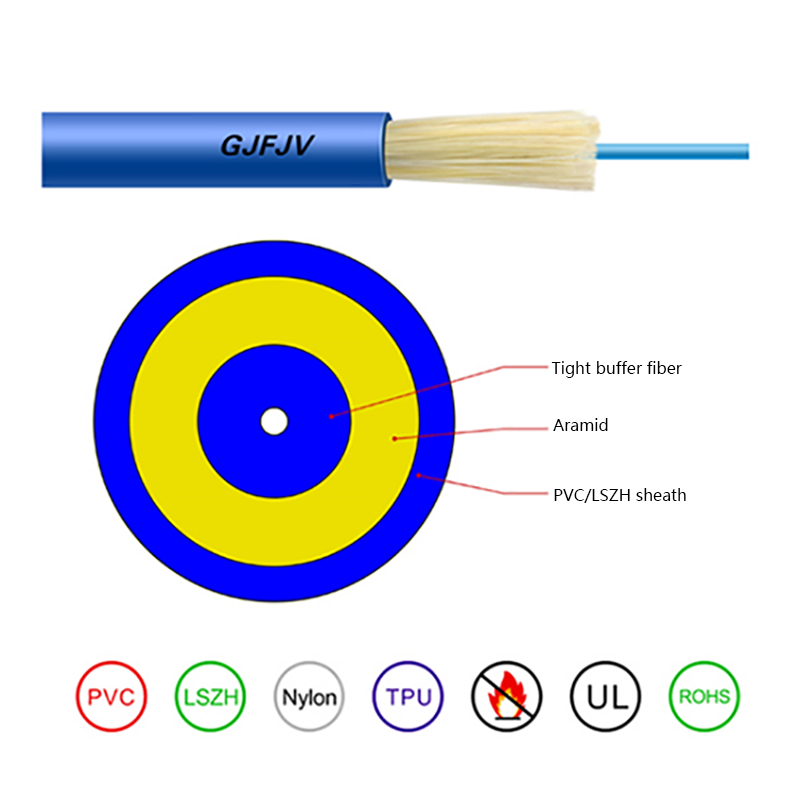

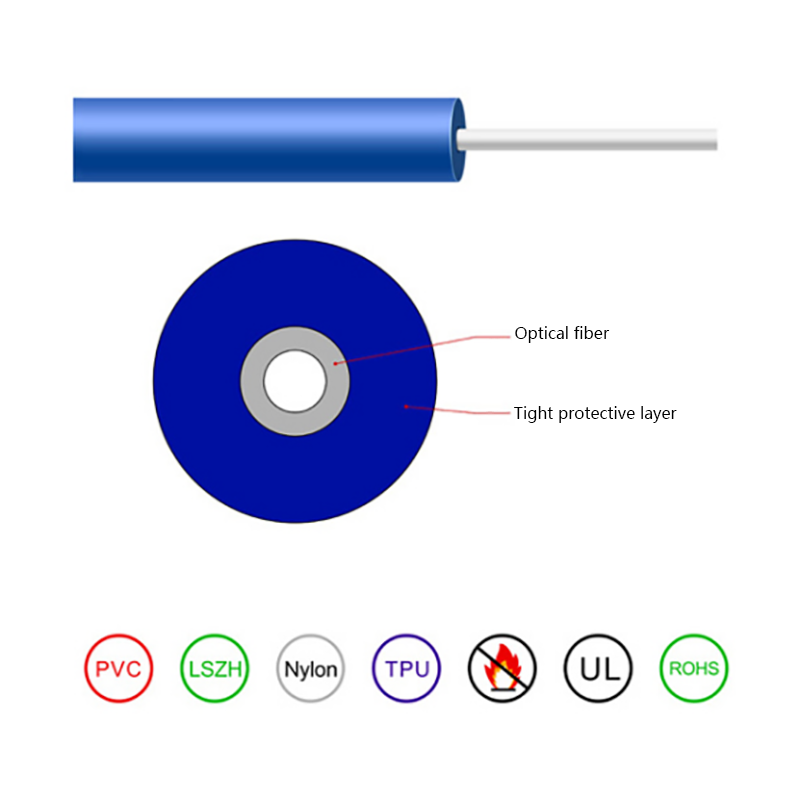

3. Material Composition of Air Blown Micro Cables

The temperature resistance of ABMCs depends heavily on their material composition. Key components include:

3.1. Outer Jacket

- Typically made from high-density polyethylene (HDPE) or low-smoke zero-halogen (LSZH) materials.

- HDPE offers excellent flexibility in cold conditions, retaining its shape at temperatures as low as -40°C.

- LSZH is often used for indoor applications, capable of withstanding temperatures up to 70°C without degradation.

3.2. Microduct Tube

- The hollow tube inside which fibers are blown is designed to maintain a consistent internal diameter even under temperature variations.

- Most microducts are made from polyethylene or polypropylene with UV stabilizers for outdoor use, capable of tolerating -30°C to 70°C routinely, and in some cases up to 85°C for high-heat environments.

3.3. Optical Fibers

- The fibers themselves are silica-based, inherently resistant to extreme temperatures.

- The protective coatings on fibers (acrylate or dual-layer coatings) are designed to maintain flexibility and prevent microbending within -40°C to 85°C ranges.

4. Laboratory Testing and Standards

Manufacturers of ABMCs perform rigorous tests to ensure temperature resilience:

-

Thermal Cycling Tests: Cables are exposed to repeated cycles of high and low temperatures to simulate seasonal and daily fluctuations.

-

Heat Aging: Long-term exposure to elevated temperatures to evaluate material degradation.

-

Cold Bend Tests: Evaluates cable flexibility at low temperatures to ensure fibers do not fracture during installation or operation.

-

Standards Compliance:

- IEC 60794: International standard for optical fiber cables, including temperature ratings.

- ITU-T G.657: Guidelines for bend-insensitive fibers, which help maintain performance under thermal stress.

These tests provide data on maximum operating temperatures, expected performance over time, and safety margins for installation in extreme climates.

5. Practical Temperature Resistance of ABMCs

Based on material design and laboratory testing, air blown micro cables typically withstand:

| Component | Temperature Range |

| HDPE Outer Jacket | -40°C to 85°C |

| LSZH Indoor Jacket | 0°C to 70°C |

| Microduct Tube | -30°C to 70°C (up to 85°C) |

| Optical Fiber Coating | -40°C to 85°C |

These ranges make ABMCs suitable for:

- Outdoor urban and suburban networks

- Indoor deployments with temperature-controlled environments

- Regions with significant seasonal variations

It is important to note that extreme conditions outside these ranges—such as desert heat above 90°C or Arctic cold below -50°C—may require specially engineered cables.

6. Installation Considerations in Temperature-Variable Environments

Even if a cable is rated for wide temperature ranges, installation techniques significantly affect performance:

-

Pre-Conditioning:

- In extremely cold weather, cables may need to be warmed to improve flexibility for blowing.

-

Proper Duct Selection:

- Microducts with low thermal expansion reduce stress on cables during temperature swings.

-

Blowing Pressure Adjustments:

- Air pressure during installation may need to be adjusted to compensate for changes in material stiffness caused by temperature.

-

Avoiding Direct Sunlight Exposure During Installation:

- High temperatures during installation can temporarily soften the jacket, making it prone to deformation if excessive tension is applied.

7. Long-Term Reliability in Variable Climates

Air blown micro cables are designed to absorb thermal stress over time without significant performance degradation. Several factors contribute to their long-term reliability:

- Flexible Jacket and Buffer: Reduce microbending even when the cable expands or contracts.

- Modular Design: Individual fibers can be replaced without disturbing the entire cable, minimizing downtime.

- UV Stabilizers: Outdoor micro cables resist thermal and ultraviolet degradation.

- Low Water Absorption: Prevents damage from freezing and thawing cycles, particularly in outdoor environments.

Field studies have shown that ABMCs in regions with temperature variations from -30°C to 50°C maintain low signal attenuation and exhibit minimal physical wear over a decade of operation.

8. Mitigation Strategies for Extreme Temperatures

For deployments in extreme climates:

-

Cold Climates (-40°C to -20°C):

- Use cables with enhanced low-temperature flexibility.

- Pre-warm the microducts or cables before installation.

- Avoid sharp bends to reduce risk of fiber cracking.

-

Hot Climates (50°C to 85°C):

- Select cables with high heat-resistant jackets.

- Consider shading outdoor ducts to reduce solar heating.

- Monitor for thermal expansion and stress on support structures.

-

Rapid Temperature Fluctuations:

- Implement cable slack loops to absorb expansion/contraction.

- Regularly inspect outdoor network segments for signs of material fatigue.

9. Case Studies and Field Performance

Case Study 1: Urban FTTH Deployment

In a European city with winter temperatures as low as -25°C and summer highs of 35°C, ABMCs were installed in pre-laid microducts. After five years:

- Fiber performance remained consistent.

- No microbending issues were observed.

- Expansion and contraction were absorbed by the duct and cable flexibility.

Case Study 2: Data Center Backbone

A data center installed ABMCs in indoor environments ranging from 18°C to 27°C daily. The temperature fluctuations had no impact on signal quality, demonstrating that ABMCs handle minor indoor variations with ease.

10. Conclusion

Air blown micro cables offer excellent resistance to temperature fluctuations, provided they are correctly specified and installed. Their flexible design, high-quality materials, and adherence to international standards allow them to operate reliably across a wide temperature range:

- Outdoor HDPE jackets: -40°C to 85°C

- Indoor LSZH jackets: 0°C to 70°C

- Fiber coatings: -40°C to 85°C

Key considerations for maximizing temperature resilience include appropriate duct selection, installation techniques, and mitigation strategies for extreme climates. With these measures, air blown micro cables can maintain long-term performance, making them a preferred choice for modern fiber optic networks that demand both scalability and environmental resilience.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体