The Strategic Edge of ADSS Cable in Modern Network Infrastructure

In today’s rapidly evolving communications landscape, the demand for resilient, high-performance cabling systems is at an all-time high. Among the front-runners of this technological arms race is ADSS cable—short for All-Dielectric Self-Supporting cable—a marvel of engineering that is quietly transforming how utility companies and service providers build out their networks.

ADSS cable is not merely another entry in the extensive catalogue of fiber optic solutions; it is a purpose-built asset designed to endure extreme environmental conditions while delivering consistent, high-bandwidth performance. Unencumbered by the need for metallic components or external support structures, this cable type distinguishes itself through its simplicity, strength, and strategic deployment flexibility.

What Makes ADSS Cable Stand Out?

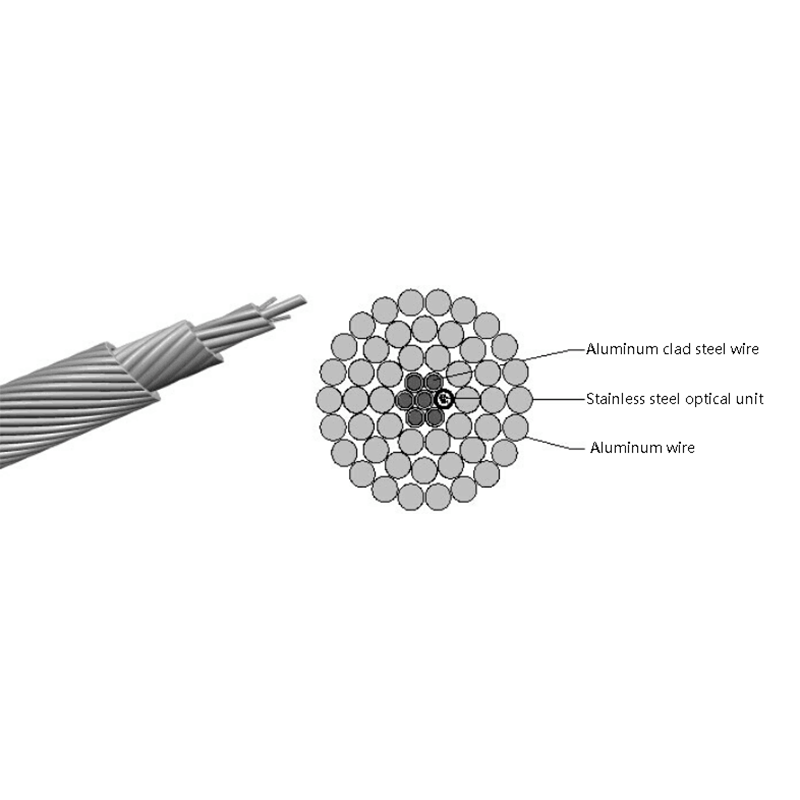

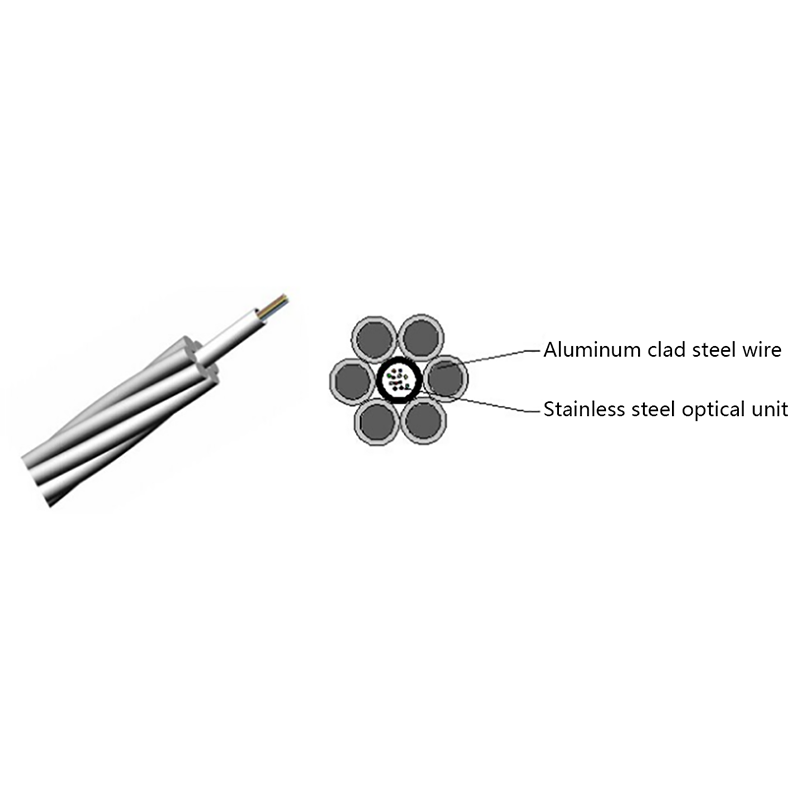

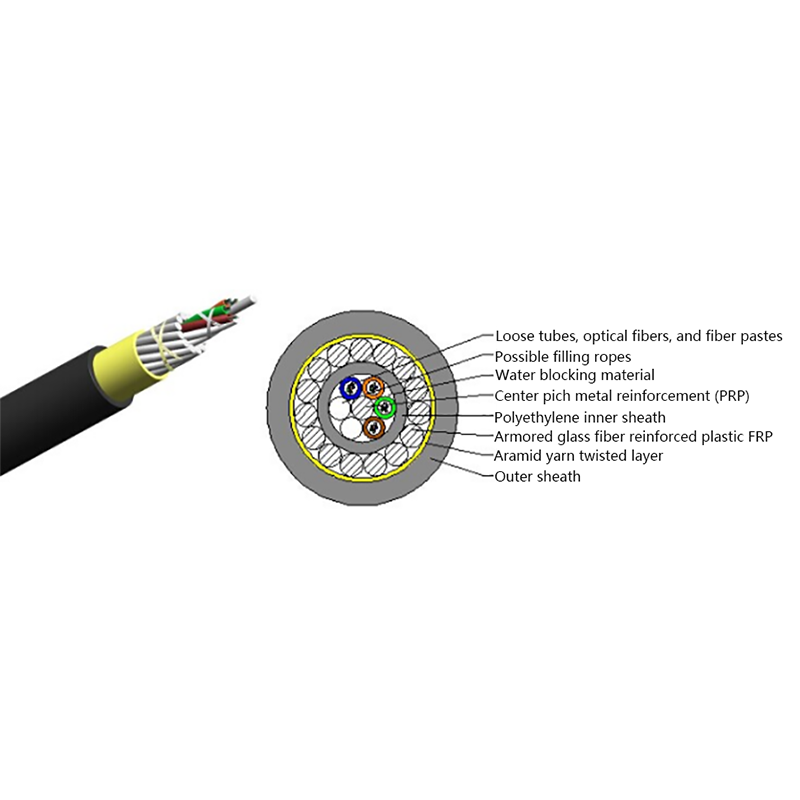

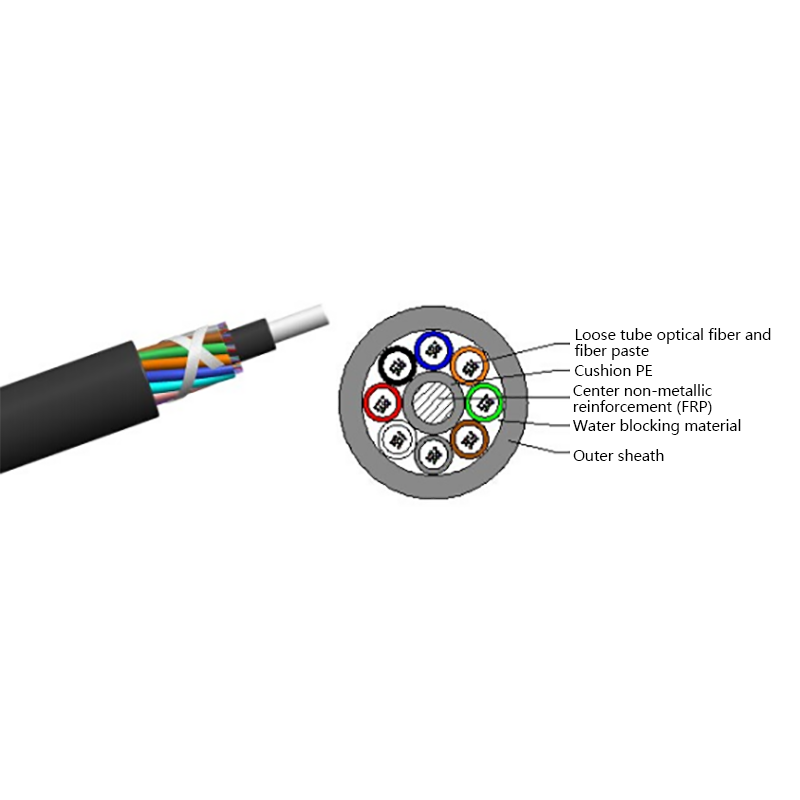

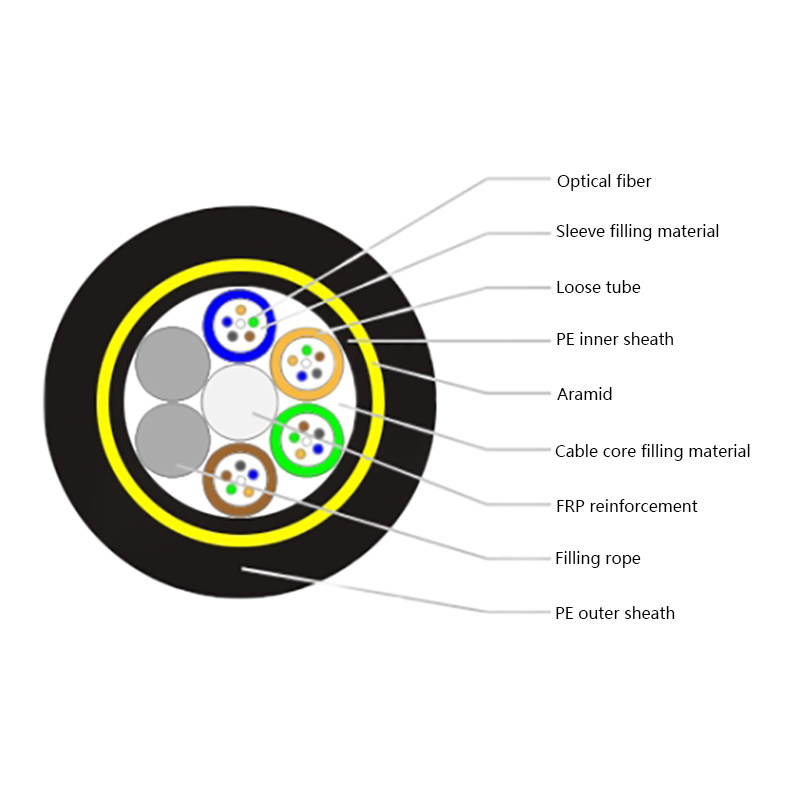

The brilliance of ADSS lies in its all-dielectric design—constructed without any metallic elements, it’s inherently immune to electromagnetic interference. This allows ADSS cables to be installed in close proximity to high-voltage power lines without risk of signal degradation. More critically, they can be installed on the same structures that support electrical lines, eliminating the need for separate support systems. The result is a leaner, more cost-efficient network buildout.

In addition, ADSS cables are engineered to be self-supporting. That means they don’t require messenger wires or lashing for overhead deployment. The tensile strength of the cable is robust enough to withstand the physical demands of aerial installation, including wind loading, ice accumulation, and long span lengths—up to several hundred meters in some configurations.

The Benefits Are Substantial

1. Cost-Efficiency:

ADSS cable significantly reduces installation costs. Because it uses existing utility infrastructure, there is minimal need for new poles, conduits, or labor-intensive trenching. Fewer materials, faster deployment—these elements directly translate to reduced capital expenditures.

2. Accelerated Installation:

Its lightweight and streamlined design means that ADSS can be deployed quickly, even in challenging terrains like mountains, forests, or across rivers. With the right equipment, technicians can string kilometers of cable in a single day, dramatically shortening the project timeline.

3. Environmental Resilience:

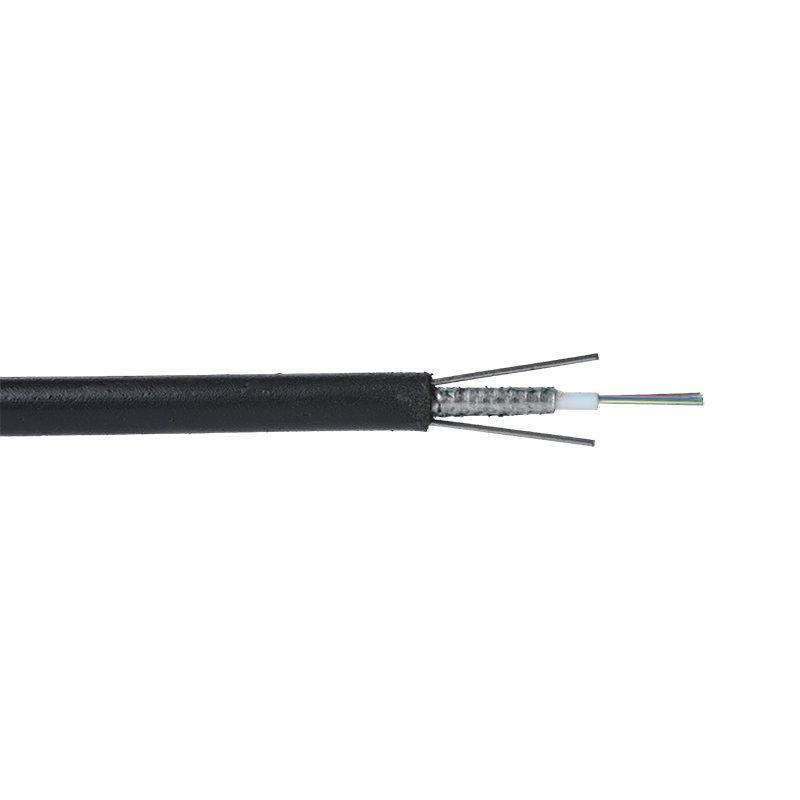

ADSS is built to last. The cable’s outer sheath is typically made from UV-resistant, water-blocking materials, offering long-term protection from solar radiation, moisture ingress, and chemical exposure. Some variants are rated for use in hurricane-prone regions, arctic conditions, or heavily polluted urban environments.

4. Enhanced Safety:

Since there’s no metal involved, ADSS eliminates the risk of electrical conduction in the event of contact with high-voltage lines. This makes it a safer option for both installation teams and the end environment.

Ideal Use Cases

ADSS cable finds its sweet spot in the utility sector—especially among electric power companies needing to expand fiber optic networks over long distances. It is equally valuable in rural broadband projects, municipal backbones, and rail or highway corridors where trenching is impractical or prohibitively expensive.

Furthermore, as smart grid initiatives and IoT deployments expand, the need for real-time data transmission between dispersed nodes makes ADSS a critical player in next-generation infrastructure.

ADSS cable is more than just a conduit for data—it's a strategic enabler. It empowers utility providers to scale networks swiftly, securely, and economically without compromising on performance. As the world leans deeper into fiber-fed technologies and data-hungry applications, the deployment of smart, resilient cabling like ADSS will continue to play a pivotal role.

In a landscape where downtime is disastrous and speed is paramount, ADSS cable offers a rare blend of reliability and agility. It’s not just built to perform. It’s engineered to outlast.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体