Air Blown Micro Cables: The Efficient Future of Fiber Deployment

In the relentless pursuit of faster, more reliable connectivity, network operators constantly seek smarter infrastructure solutions. Enter Air Blown Micro Cables (ABCs) – a revolutionary approach to fiber optic cable installation that’s transforming how we build networks. Unlike traditional cables pulled through ducts, ABCs are dynamically installed using compressed air, offering unparalleled flexibility and efficiency, particularly for high-density fiber networks.

What Exactly Are Air Blown Micro Cables?

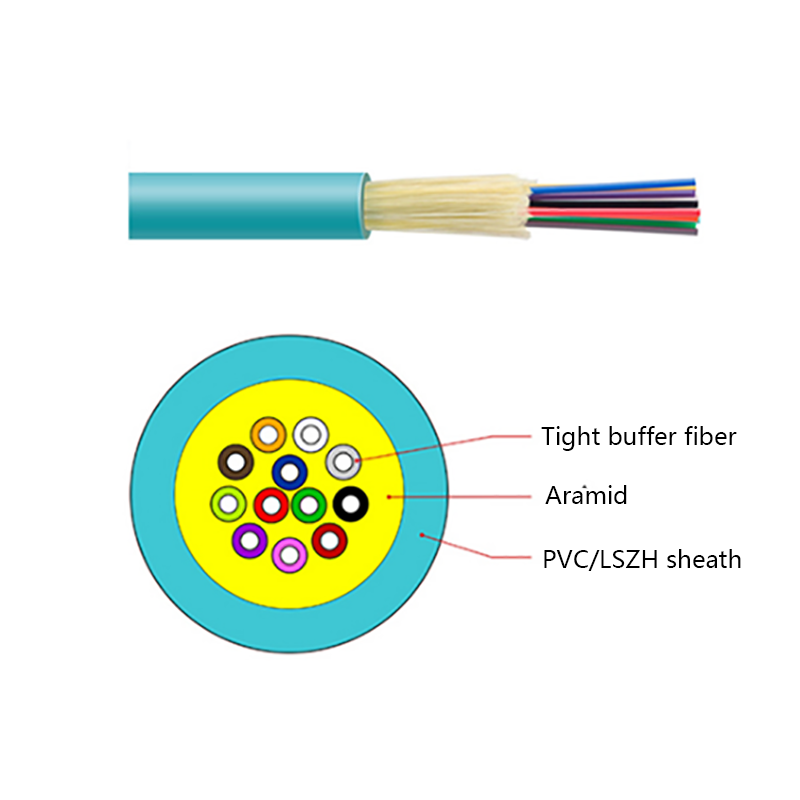

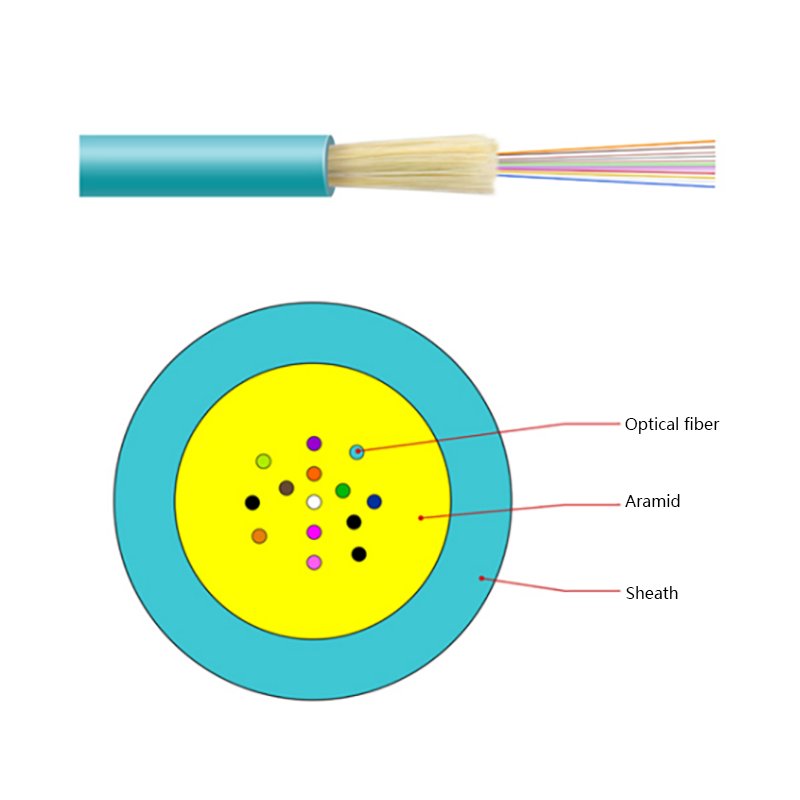

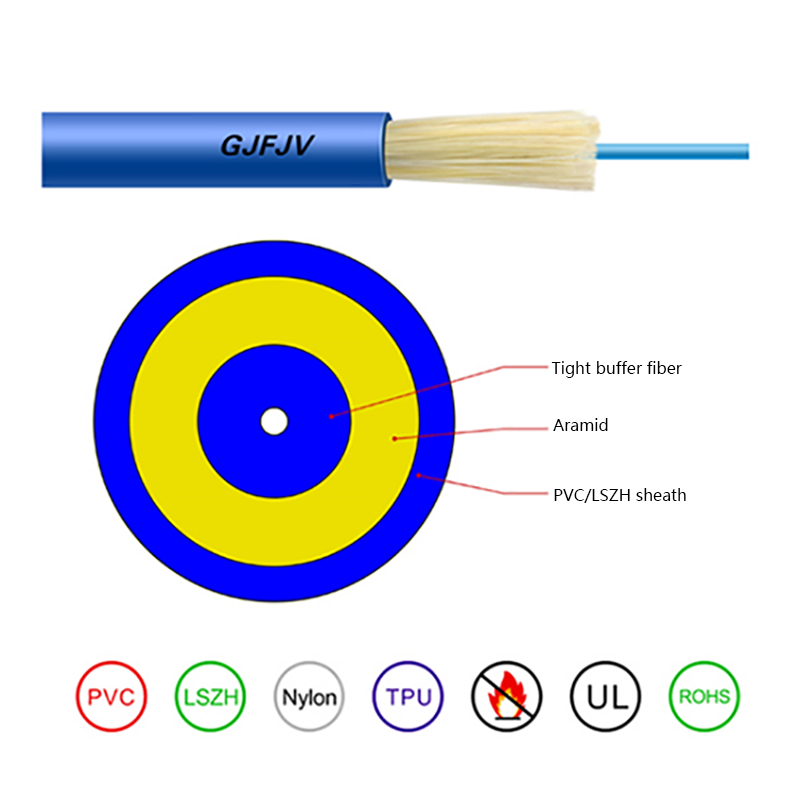

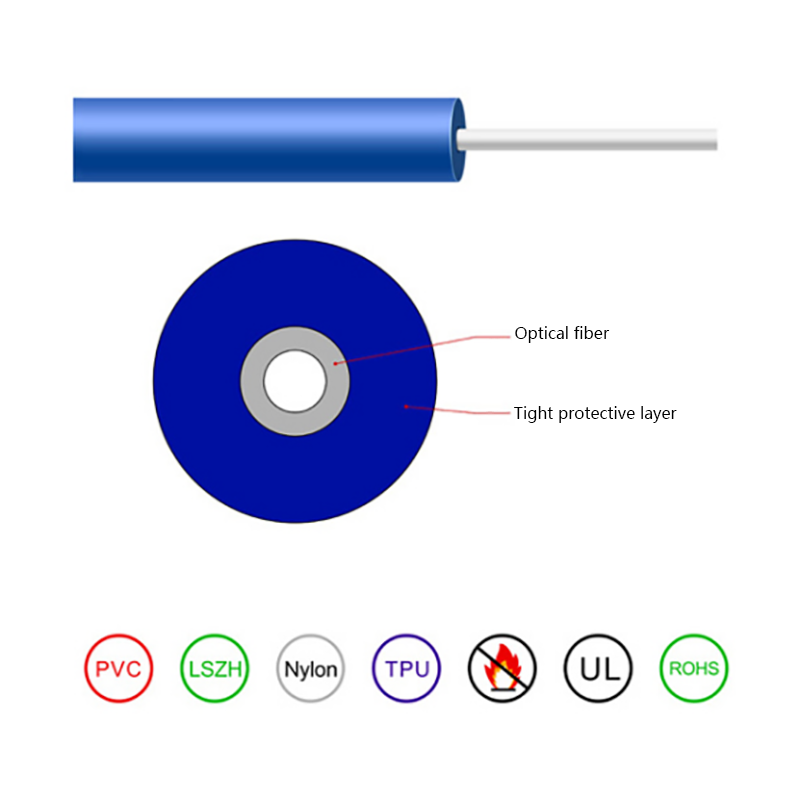

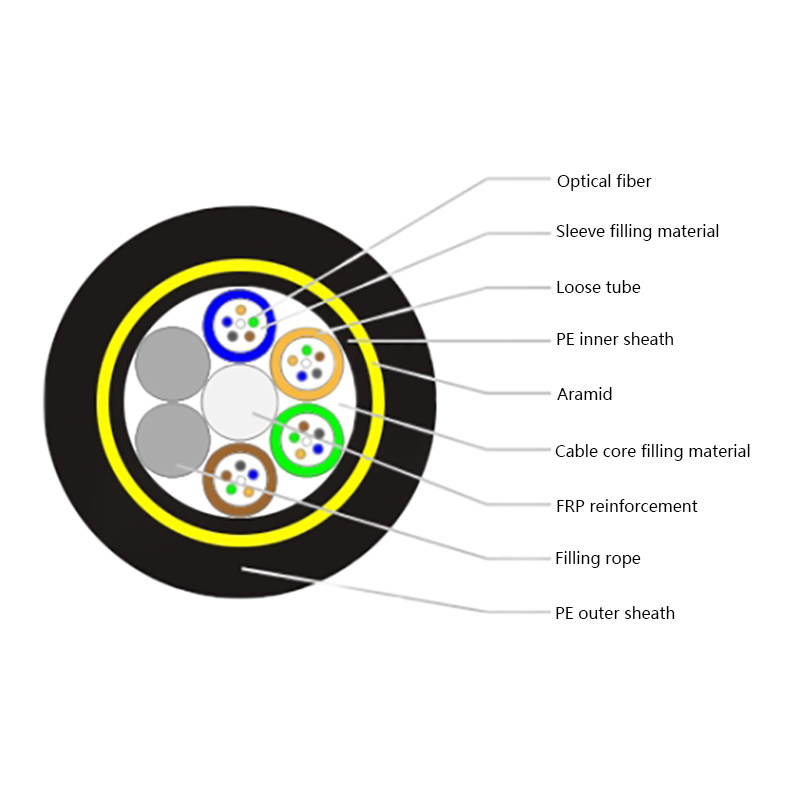

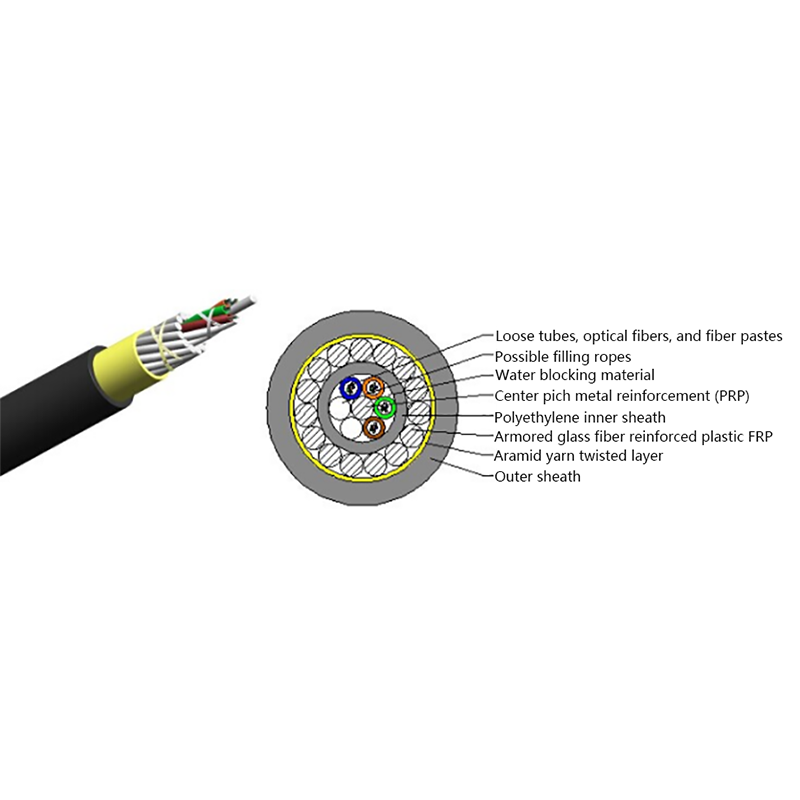

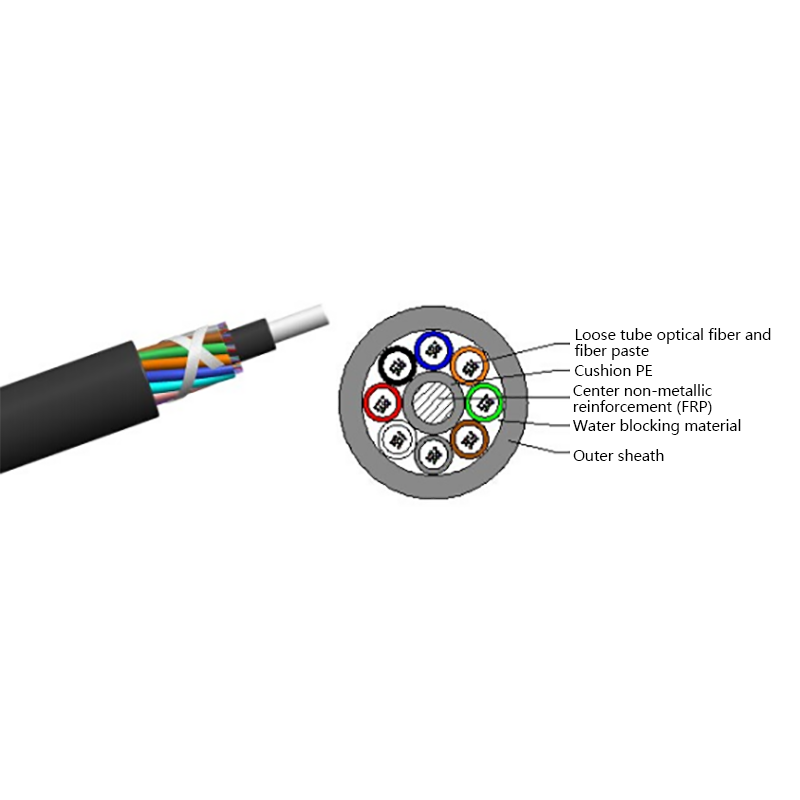

At their core, ABCs are miniature fiber optic cables, significantly smaller in diameter than traditional loose tube or ribbon cables. They consist of:

Ultra-Slim Sheath: A smooth, durable outer jacket designed for minimal friction.

Buffer Tubes: Housing individual optical fibers, often in compact designs.

Reinforcement: Lightweight strength members (like aramid yarn or fiberglass rods) to protect the delicate fibers during installation and service.

Their defining characteristic is their installation method: compressed air blowing. Specialized equipment propels the cable through pre-installed microducts using a controlled stream of air, significantly reducing physical stress on the cable.

The Installation Revolution: How ABCs Work

Microduct Installation: First, a bundle of small, flexible plastic tubes (microducts) is installed within a larger protective duct or conduit. This is the foundational fiber pathway infrastructure.

Cable Preparation: The chosen microcable, stored on a reel, is fed into the blowing head.

Air Blowing: A cable blowing machine generates compressed air, which flows around the cable inside the microduct. This air creates a viscous drag force that propels the cable forward with remarkable speed and over long distances with minimal pulling tension.

Termination: Once blown through the microduct pathway, the cable is terminated at splice points or network equipment.

Key Advantages of the Air Blown Approach

ABC technology offers compelling benefits over traditional cable pulling:

Unmatched Speed and Distance: Cable can be installed hundreds or even thousands of meters in a single run, often much faster than pulling.

Reduced Installation Force: The air-blowing technique exerts far less tension on the cable, drastically lowering the risk of fiber damage during deployment (low tension fiber installation).

Minimized Duct Congestion: Microduct bundles occupy less space than large traditional cables, allowing for higher fiber counts within existing infrastructure (conduit space optimization).

Future-Proofing & Scalability: Empty microducts can be installed initially. When demand arises, new microcables can be blown into these empty ducts without disrupting existing services. This enables just-in-time fiber deployment and modular network expansion.

Lower Risk & Cost: Reduced physical stress means fewer installation faults and breakages. The speed of installation lowers labor costs. Scalability defers capital expenditure.

Accessibility: Suitable for challenging routes (tight bends, congested ducts, risers) where pulling is difficult or impossible.

Air Blown Micro Cables vs. Traditional Pulled Cables

| Feature | Air Blown Micro Cables (ABCs) | Traditional Pulled Cables |

|---|---|---|

| Installation Method | Blown using compressed air through microducts | Physically pulled through ducts/conduit |

| Cable Diameter | Very small (typically 3mm - 10mm) | Larger (typically 10mm - 20mm+) |

| Installation Force | Very Low Tension | High Pulling Tension |

| Installation Speed | Generally Very Fast | Slower |

| Max Installation Distance | Very Long (Often 1km-2km+ per blow) | Shorter (Limited by friction/tension) |

| Fiber Density | High (via multiple microducts in one pathway) | Lower (Limited by duct size) |

| Future Upgrades | Easy - Blow new cable into spare microducts | Difficult - Often requires new duct installation |

| Initial Duct Investment | Requires microduct bundle installation | Direct cable placement in duct/conduit |

| Best Suited For | High-density fiber pathways, future-proof networks, congested ducts, long runs, frequent upgrades | Simpler, smaller scale deployments, direct burial, aerial |

Core Applications: Where ABCs Shine

Fiber to the Home (FTTH / FTTx): The backbone of modern fiber access networks, enabling efficient deployment from central offices to neighborhoods and individual premises.

Data Center Interconnects (DCI): Providing scalable fiber links between data centers or within large campus environments.

Mobile Backhaul/Fronthaul (5G/6G): Essential for connecting the dense network of small cell sites required by next-generation mobile networks.

Building Infrastructure: Ideal for riser cable solutions and horizontal cabling within multi-tenant buildings (MDUs/MTUs).

Network Expansion & Upgrades: The go-to solution for adding fiber capacity to existing conduit systems without excavation (minimal disruption cabling).

The Future is Modular and Scalable

The shift towards ABC systems represents a fundamental change in network planning philosophy. Instead of installing large, fixed-capacity cables for projected long-term needs, operators deploy the microduct infrastructure upfront. Fiber blowing then allows for demand-driven cabling – deploying exactly the fiber count needed, exactly when it’s needed. This modular optical infrastructure drastically improves capital efficiency and network agility.

Key Considerations

Microduct Quality: The performance of the ABC system heavily depends on high-quality, smooth-walled microducts.

Trained Personnel: Proper installation requires specialized blowing equipment and trained technicians familiar with the techniques.

Initial Investment: Setting up the microduct pathways requires an upfront investment, though the TCO is often lower.

Compatibility: Ensure cable and microduct specifications (size, friction coefficient) are compatible for optimal blowing performance.

Conclusion

Air Blown Micro Cables are far more than just another cable type; they represent a smarter, more efficient methodology for deploying fiber optic networks. By enabling faster installation, reducing damage risk, maximizing duct utilization, and offering unparalleled scalability for future growth, ABC systems are becoming the cornerstone of modern optical infrastructure. For network operators prioritizing long-term cost efficiency, rapid deployment, and future-ready networks, embracing the air-blown micro cable approach is a strategic imperative. As bandwidth demands continue their exponential climb, the flexibility and efficiency of ABC technology will be crucial in building the resilient, high-capacity networks of tomorrow.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体