What Does Fiber Optic Cable Do?

Fiber optic cables transmit information as pulses of light through strands of glass or plastic. They serve as the backbone of modern telecommunications, enabling high-speed data transfer over long distances with minimal signal loss.

Core Functionality

Fiber optics convert electrical signals into light using a transmitter. Light travels through the cable via total internal reflection, bouncing between the core and cladding. At the destination, a receiver converts light back into electrical signals.

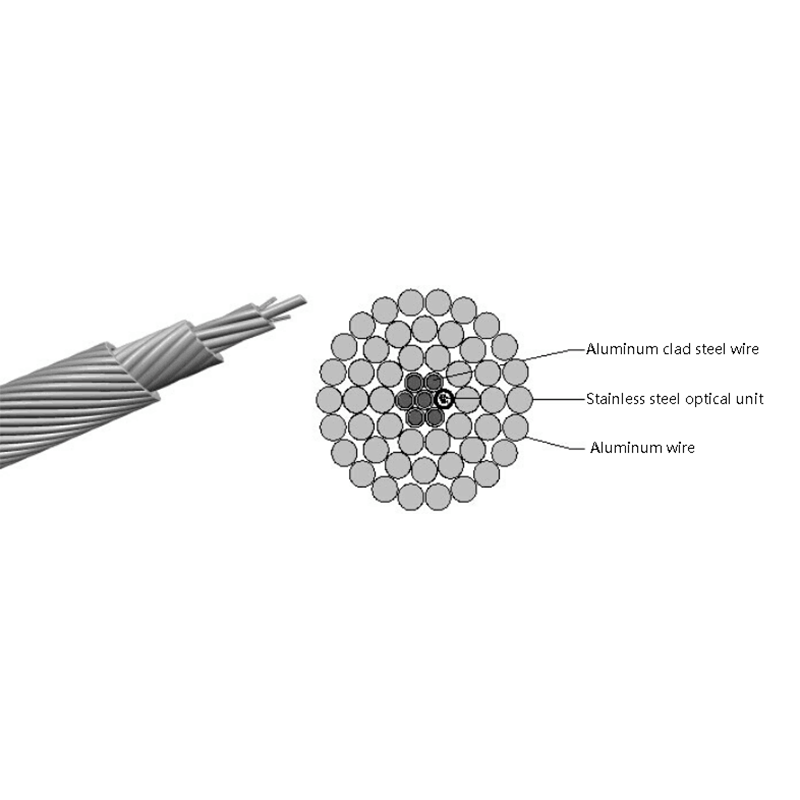

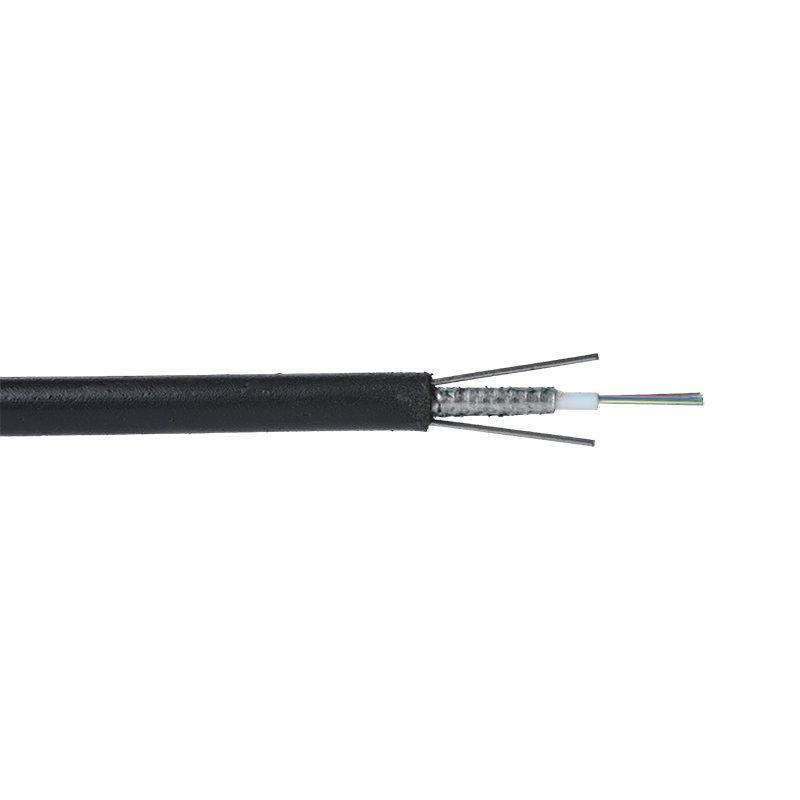

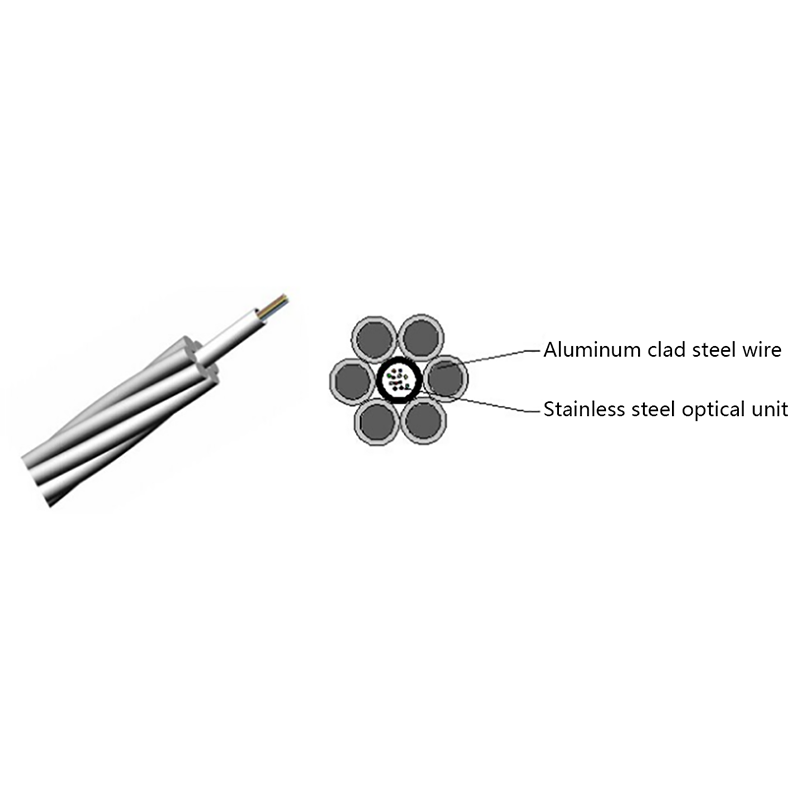

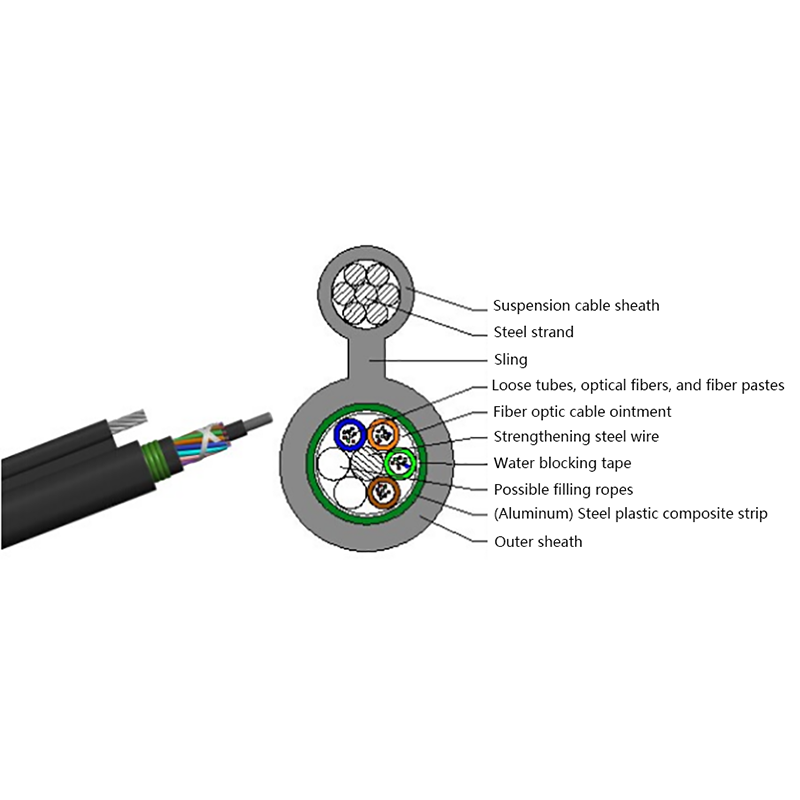

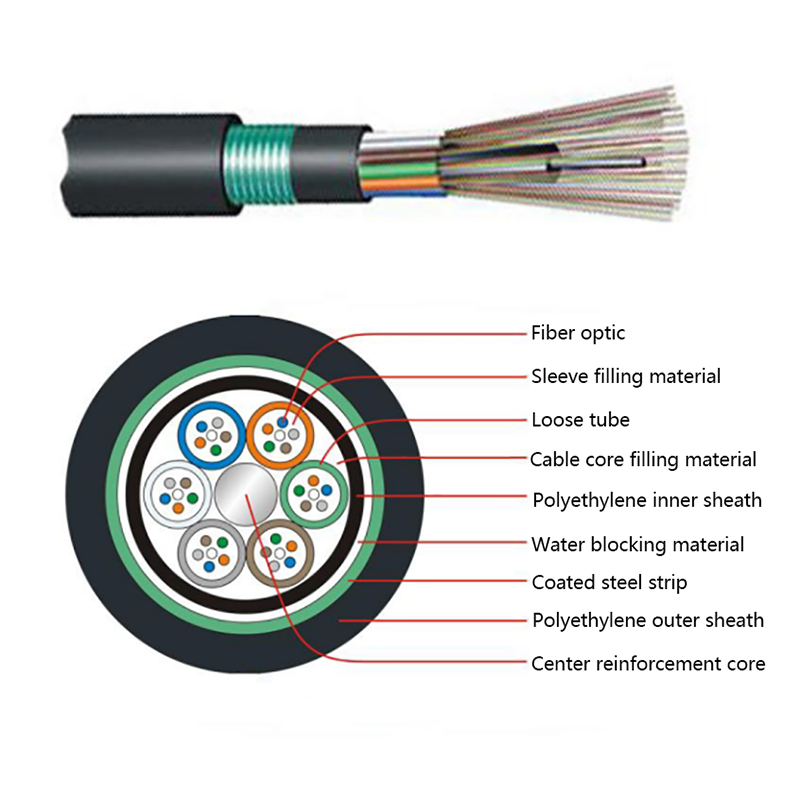

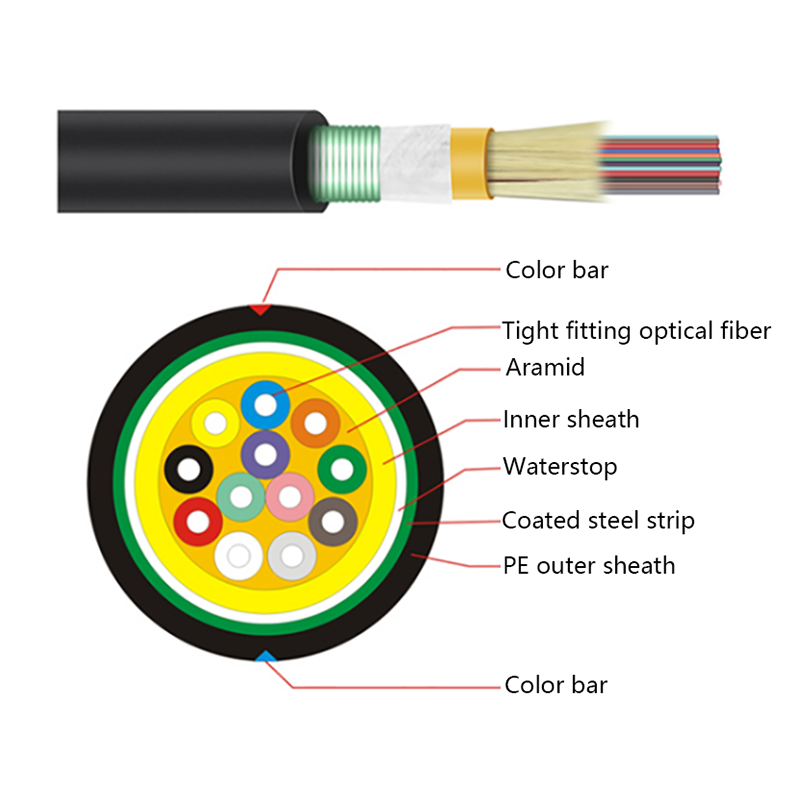

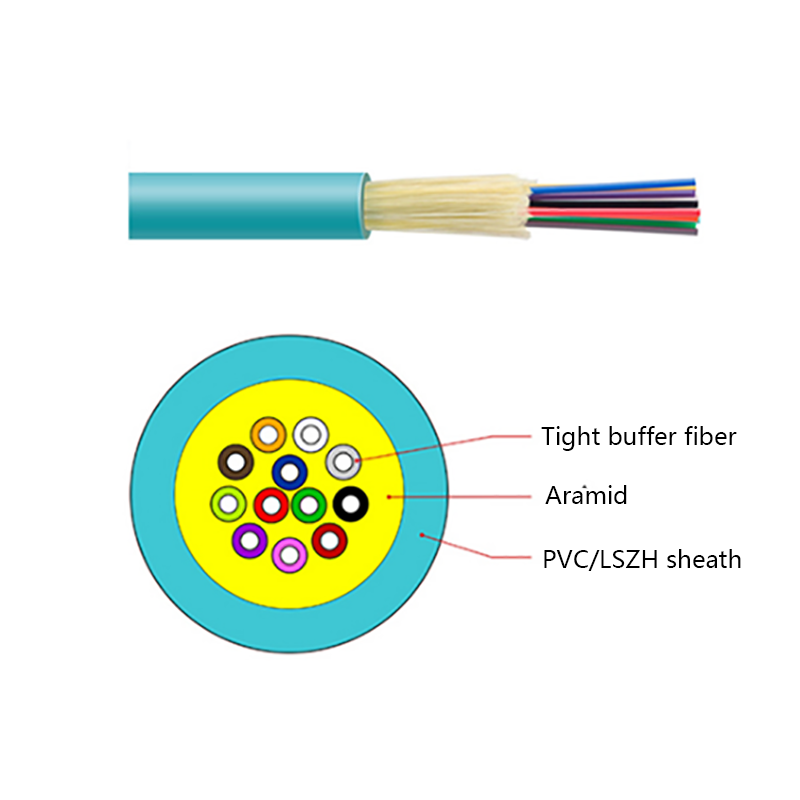

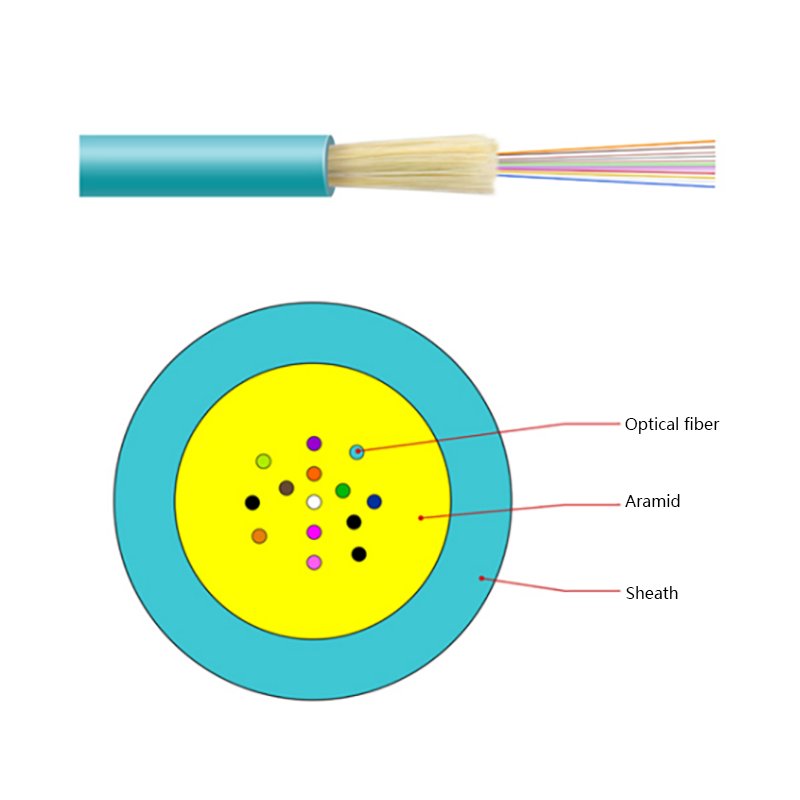

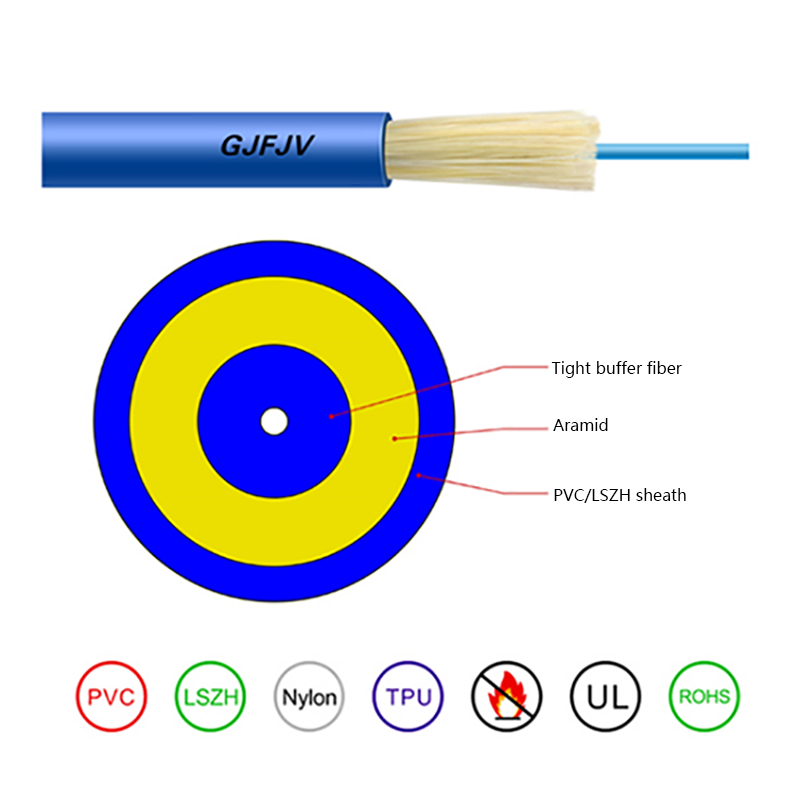

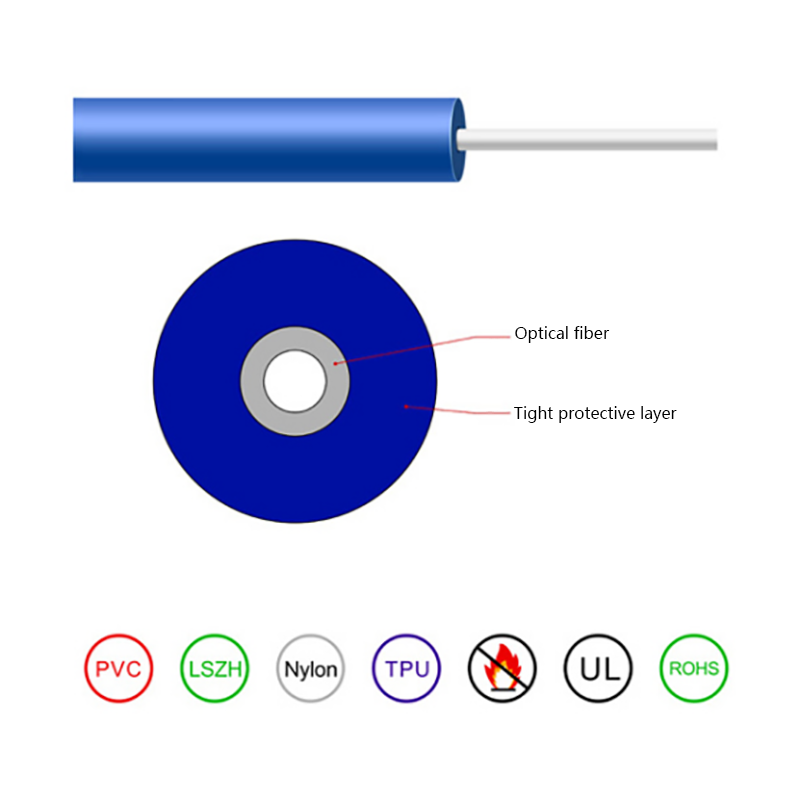

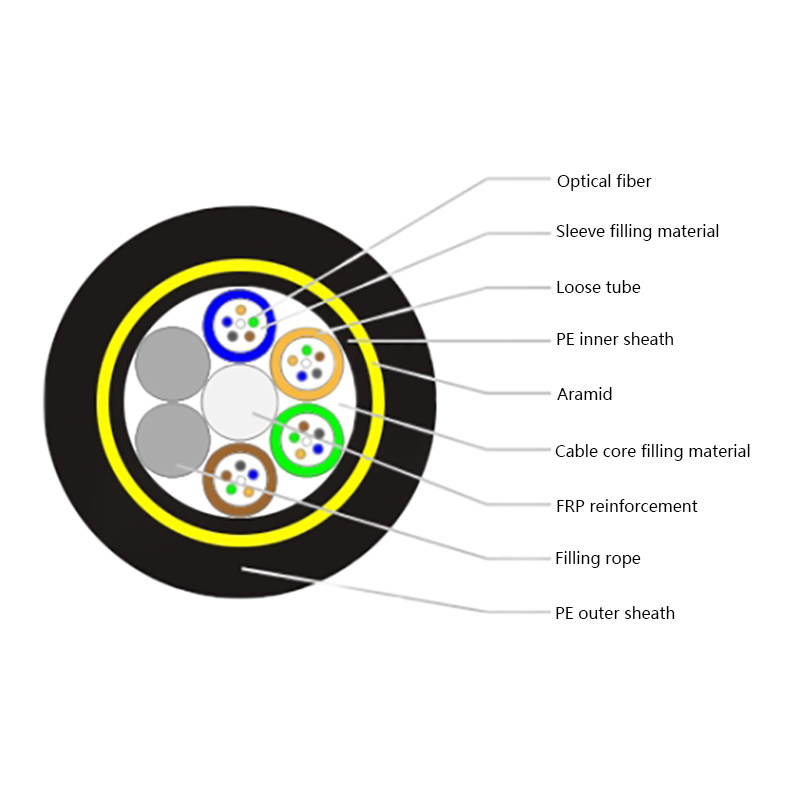

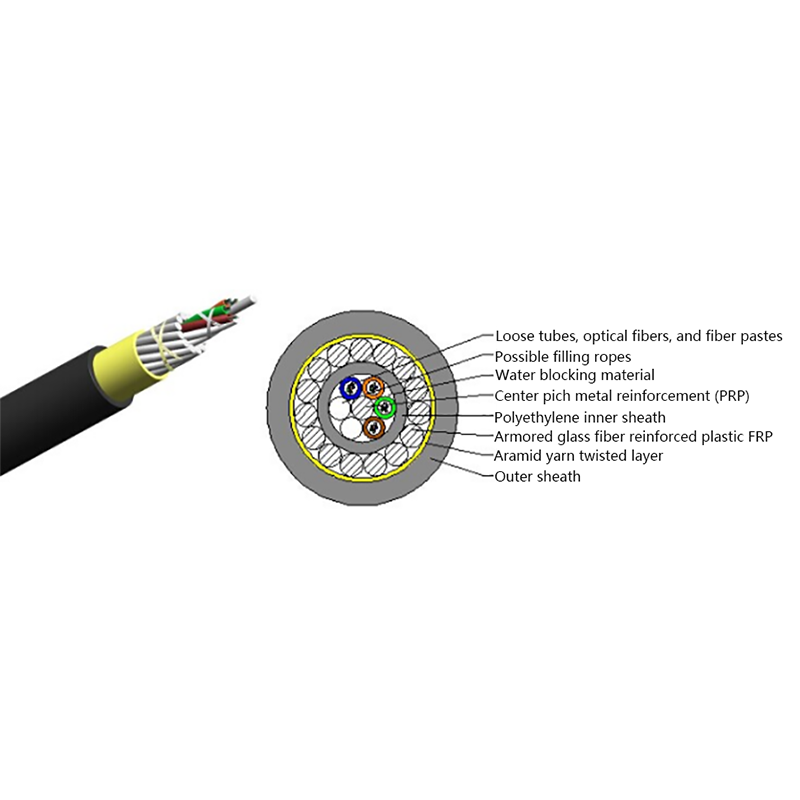

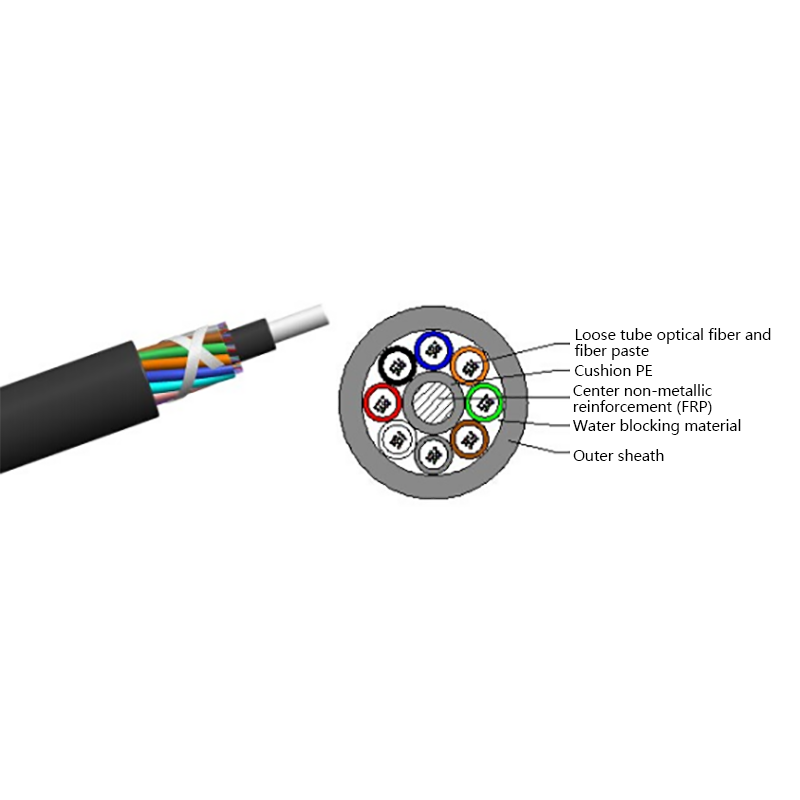

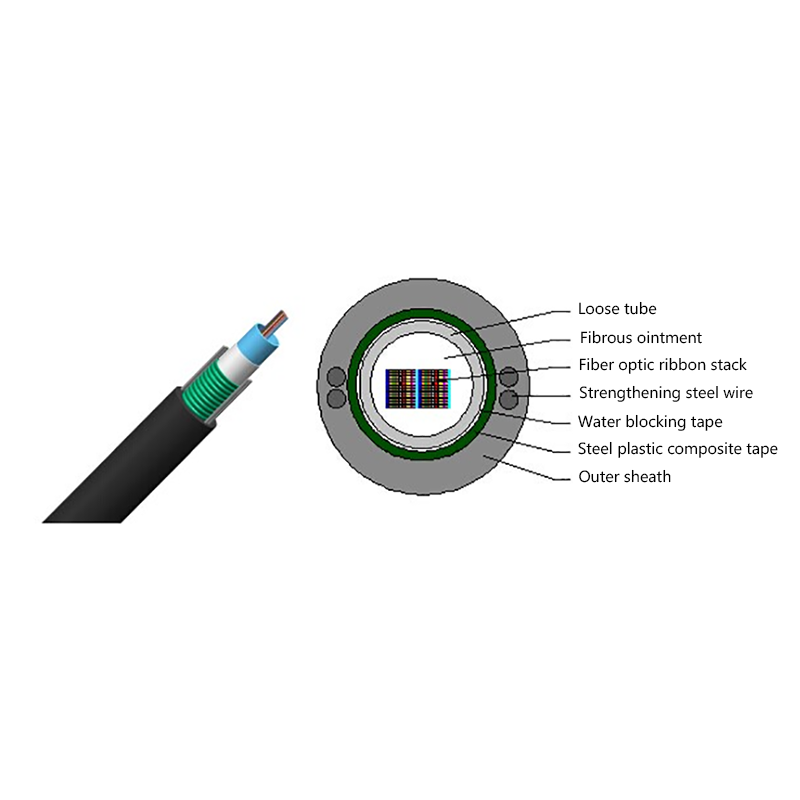

Key Components

• Core: Thin glass/plastic center carrying light

• Cladding: Outer layer reflecting light inward

• Buffer coating: Protective plastic jacket

• Strength members: Reinforcing fibers (e.g., Kevlar)

• Outer jacket: Weather-resistant exterior

Technical Specifications

Single-mode fibers (9µm core) carry infrared laser light (1310-1550nm) for distances exceeding 100km. Multimode fibers (50-62.5µm core) use LED light sources for shorter runs (≤2km).

Performance Comparison

| Feature | Fiber Optic | Coaxial Cable | Twisted Pair |

| Max Bandwidth | >100 Tbps | 10 Gbps | 10 Gbps |

| Max Distance (no repeaters) | 80-100km | 500m | 100m |

| Latency | 5μs/km | 10μs/km | 12μs/km |

| EM Interference Immunity | Complete | Moderate | Low |

| Typical Applications | Internet backbone, submarine cables | Cable TV, CCTV | Ethernet, telephony |

Signal Transmission Mechanics

Light pulses maintain signal integrity through total internal reflection. The critical angle calculation follows Snell's Law: θc = sin-1(n2/n1), where n1 and n2 are refractive indices of core and cladding.

Deployment Scenarios

• Undersea Cables: 400+ systems spanning 1.3M km globally

• FTTH (Fiber-to-the-Home): Direct consumer connections

• Data Centers: Spine-leaf architecture with 400Gbps links

• Industrial: EMI-resistant factory automation

Limitations and Considerations

Installation costs exceed copper by 10-30%. Specialized equipment required for splicing (0.1dB loss per splice). Minimum bend radius (typically 10-20× cable diameter) prevents light leakage.

Evolution Timeline

1977: First commercial installation (Chicago)

1988: TAT-8 transatlantic cable (40,000 calls simultaneously)

2016: 4,000km record (1Tbps single-channel)

2023: Subsea systems achieving 24Tbps per fiber pair

Future Developments

Space-division multiplexing using multi-core fibers (7 cores demonstrated). Hollow-core fibers reducing latency to 3μs/km. Integration with quantum cryptography networks.

Technical Deep Dive

Fiber optic systems leverage wavelength-division multiplexing (WDM) to increase capacity. Dense WDM (DWDM) supports up to 160 wavelengths per fiber, each carrying 100Gbps. Signal regeneration occurs through erbium-doped fiber amplifiers (EDFAs) spaced at 80-100km intervals, maintaining optical amplification without electrical conversion. Nonlinear effects like four-wave mixing become significant at power levels exceeding +17dBm, requiring dispersion-shifted fiber designs. Polarization mode dispersion (PMD) compensation is critical for links beyond 40km operating at 100Gbps+.

Material Science

Ultra-pure fused silica (SiO2) forms the core material, with germanium doping increasing refractive index. Cladding uses fluorine-doped silica with 0.36% lower refractive index. Manufacturing involves modified chemical vapor deposition (MCVD), where gases deposit silicon layers inside preform tubes at 1900°C. Fiber drawing occurs at 2000°C, pulling 10km/min with diameter controlled to ±0.1µm.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体