What Is Optical Ground Wire (OPGW)? - Complete Guide

Optical Ground Wire (OPGW) is a critical component in modern power transmission systems that combines the functions of grounding and communication. This comprehensive guide explains everything you need to know about OPGW technology, its applications, and benefits for power utilities and telecommunication networks.

Understanding Optical Ground Wire

OPGW is a dual-purpose cable that serves as both a ground wire for electrical power transmission lines and a communication medium through embedded optical fibers. It replaces traditional static/shield wires in overhead transmission lines while adding fiber optic communication capabilities.

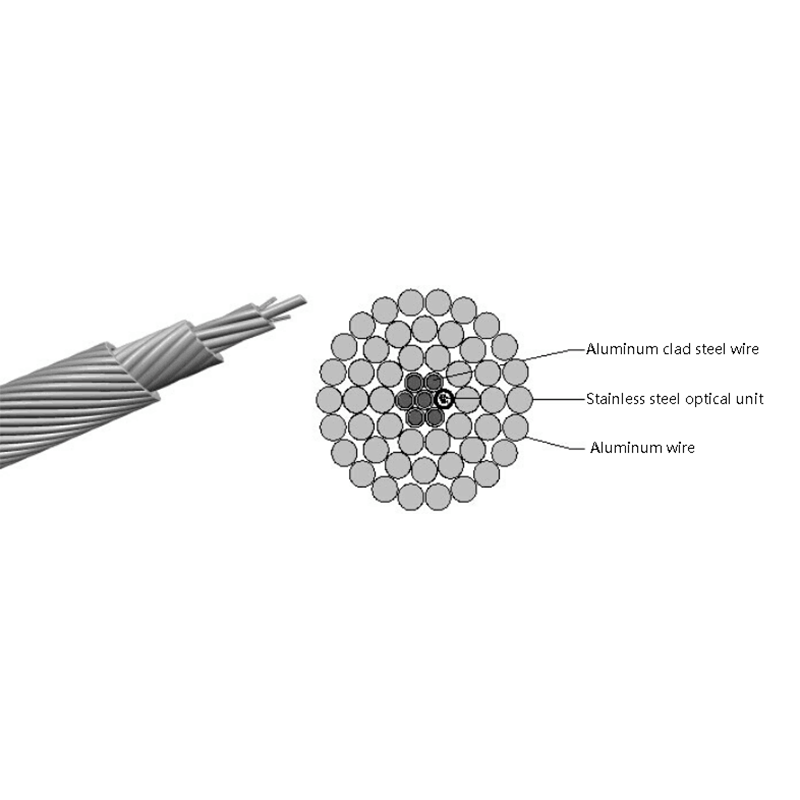

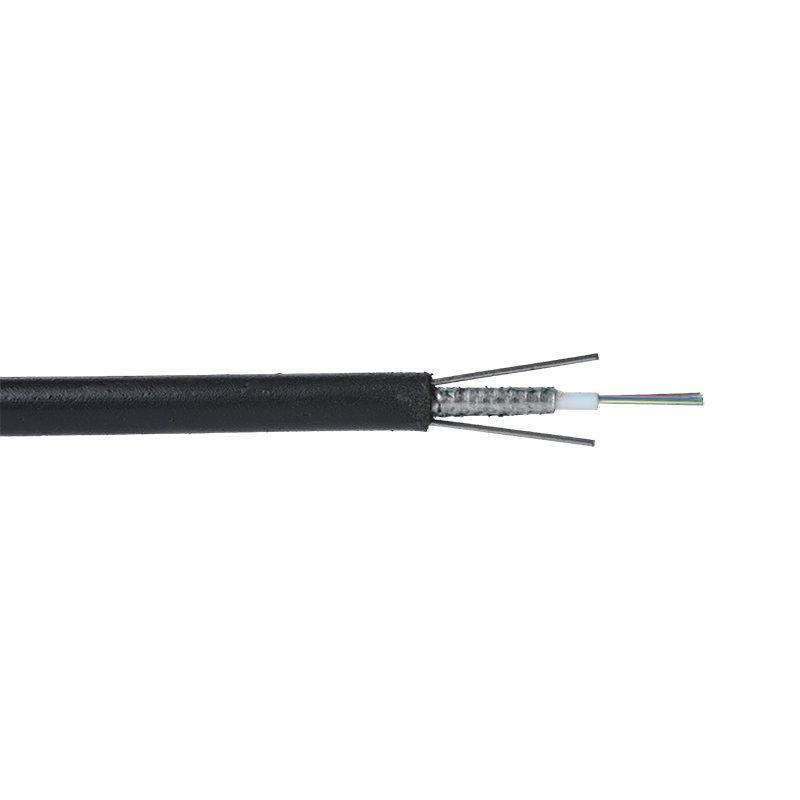

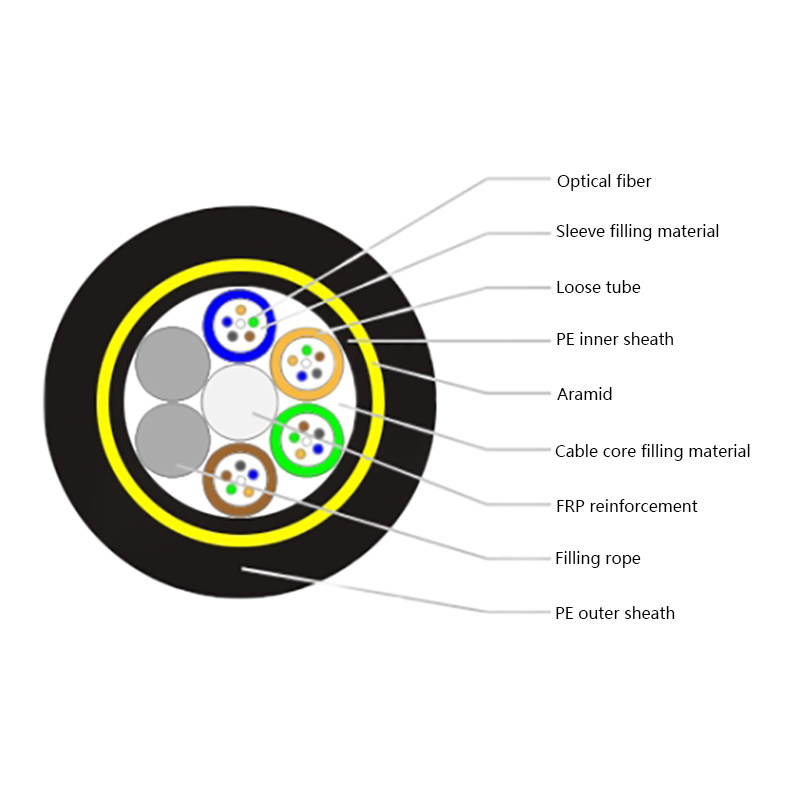

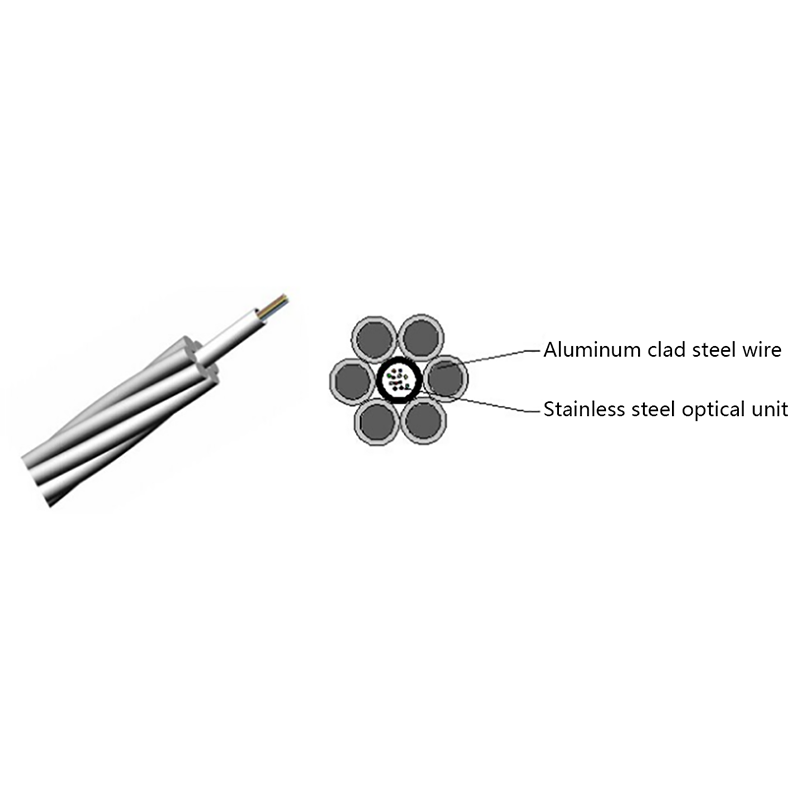

The typical OPGW cable consists of:

- Outer aluminum or aluminum alloy layers for electrical conductivity

- Stainless steel or aluminum tubes containing optical fibers

- High-strength steel wires for mechanical support

- Multiple optical fibers (typically 12-144) for data transmission

How OPGW Works in Power Systems

OPGW performs two primary functions in power transmission networks:

- Lightning Protection: Installed at the top of transmission towers, OPGW provides a shield against lightning strikes, protecting phase conductors from direct hits.

- Fault Current Carrying: During system faults, OPGW safely conducts fault currents to ground.

- Data Communication: The embedded optical fibers enable high-speed data transmission for SCADA systems, protection relaying, and telecom services.

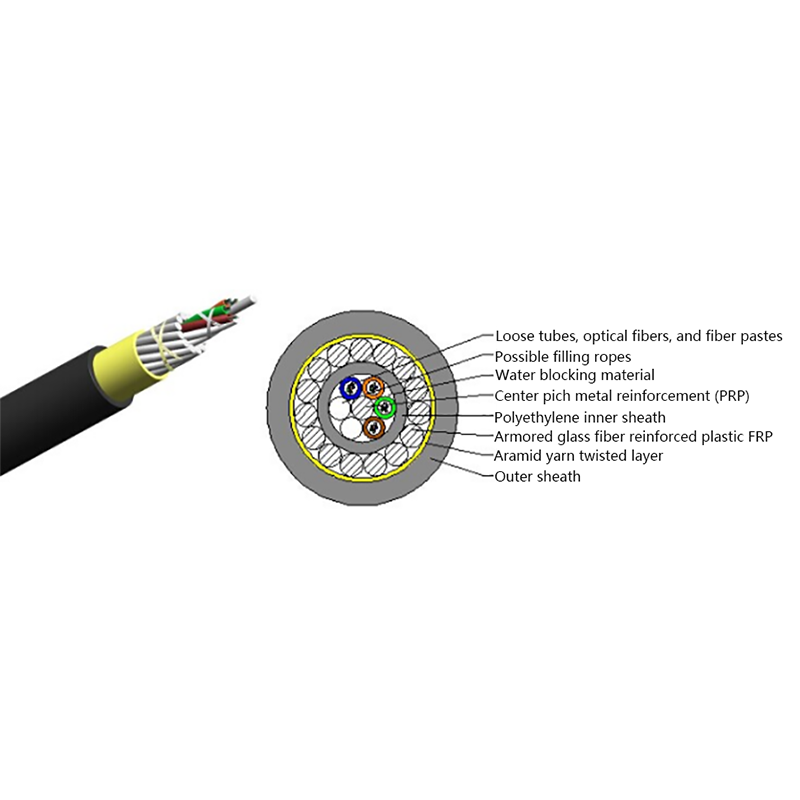

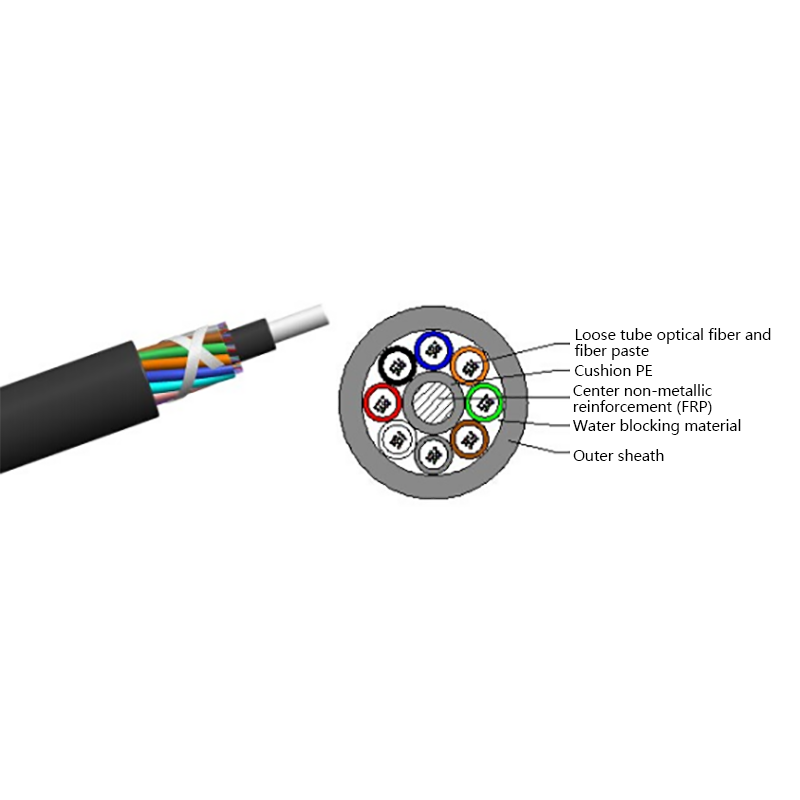

Types of OPGW Construction

There are several OPGW design configurations available:

| Type | Construction | Advantages | Typical Applications |

| Central Tube | Optical unit at core surrounded by aluminum and steel wires | Compact size, good fiber protection | Medium voltage lines, areas with moderate lightning |

| Stranded Tube | Multiple stainless steel tubes stranded with aluminum wires | Higher fiber count, better mechanical strength | High voltage transmission, areas with high lightning activity |

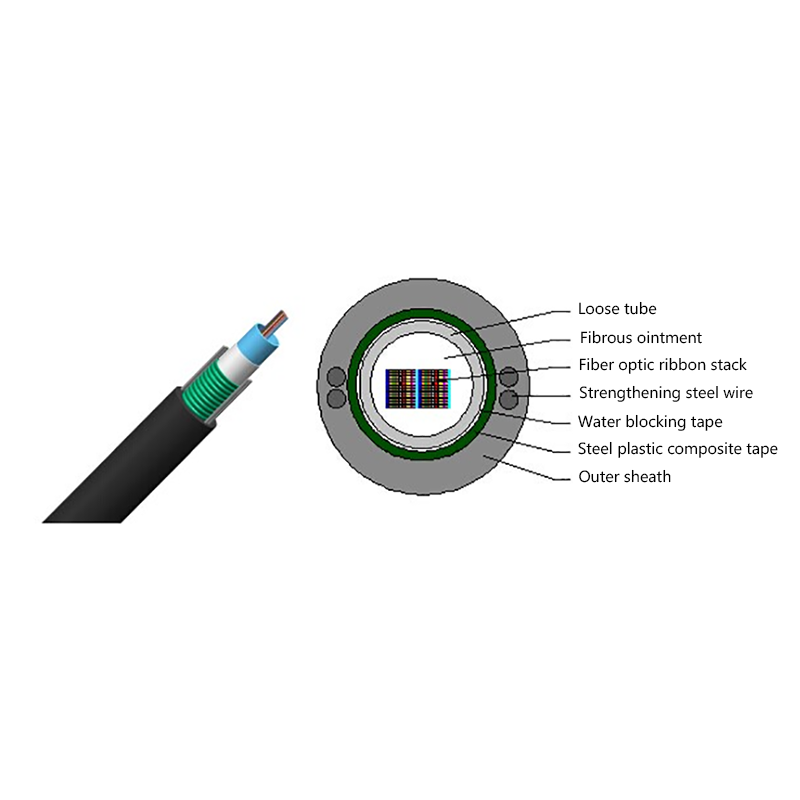

| Loose Tube | Optical fibers in loose buffer tubes within the cable | Excellent fiber protection, strain relief | Long spans, harsh environments |

| Slot Type | Fibers in a metal or plastic slot within the cable | Easy fiber access, good bending performance | Distribution lines, short spans |

Key Advantages of OPGW

OPGW offers numerous benefits for power utilities and communication providers:

Enhanced System Protection

The robust construction of OPGW provides superior lightning protection compared to conventional ground wires. The metallic components ensure reliable fault current conduction while protecting phase conductors from direct strikes.

Reliable Communication Infrastructure

OPGW creates a secure communication channel immune to electromagnetic interference (EMI), which is crucial for:

- Protection relay signaling

- SCADA system communication

- Substation automation

- Teleprotection schemes

Cost-Effective Solution

By combining grounding and communication functions in a single cable, OPGW eliminates the need for separate communication infrastructure. This results in significant cost savings in:

- Installation expenses

- Right-of-way acquisition

- Maintenance operations

OPGW Technical Specifications

When selecting OPGW for a project, engineers must consider several technical parameters:

Electrical Characteristics

- DC Resistance: Typically 0.05-0.5 ohm/km depending on aluminum content

- Short Circuit Capacity: Calculated based on fault current magnitude and duration

- Inductive Coupling: Affects communication performance in parallel circuits

Mechanical Properties

- Breaking Load: Ranges from 30 kN to 200+ kN based on design

- Weight: Typically 200-1000 kg/km depending on size and materials

- Diameter: Usually 8-20 mm

- Maximum Tension: Designed to match tower loading requirements

Optical Fiber Parameters

- Fiber Count: Commonly 12-144 fibers

- Fiber Type: Typically G.652.D single-mode fibers

- Attenuation: ≤ 0.22 dB/km at 1310 nm, ≤ 0.36 dB/km at 1550 nm

- Temperature Range: -40°C to +80°C operational

OPGW Installation Considerations

Proper installation is crucial for OPGW performance and longevity. Key factors include:

Stringing Process

OPGW installation follows similar procedures as conventional ground wires but with additional precautions:

- Use proper tensioning equipment to avoid exceeding maximum tensile load

- Maintain minimum bending radius (typically 30× cable diameter)

- Use appropriate stringing blocks with non-metallic sheaves

- Monitor fiber integrity during installation with OTDR testing

Sag and Tension Calculations

Accurate sag-tension calculations are essential for:

- Ensuring proper clearance to phase conductors

- Preventing excessive tower loading

- Maintaining fiber performance over temperature variations

Connection and Termination

Special attention must be paid to OPGW connections:

- Use proper dead-end fittings matched to the OPGW design

- Install vibration dampers in areas prone to aeolian vibration

- Properly ground the OPGW at each tower

- Seal fiber splice closures to prevent moisture ingress

OPGW Maintenance and Testing

Regular maintenance ensures long-term OPGW performance:

Visual Inspections

Periodic visual checks should examine:

- Hardware condition (clamps, dampers, spacers)

- Corrosion signs on metallic components

- Damage from external factors (birds, falling objects)

- Sag variations that may indicate tension issues

Optical Fiber Testing

Regular fiber testing includes:

- OTDR Testing: Measures fiber attenuation and locates faults

- Insertion Loss Testing: Verifies end-to-end link loss

- Chromatic Dispersion: Important for high-speed systems

Electrical Testing

- Continuity testing of the electrical path

- Ground resistance measurements

- Corrosion potential assessments

OPGW vs. Alternative Solutions

Understanding how OPGW compares to other communication solutions helps in making informed decisions:

OPGW vs. ADSS (All-Dielectric Self-Supporting)

- ADSS doesn't provide grounding function

- ADSS requires separate attachment points on towers

- OPGW offers better lightning protection

- ADSS may be preferable in lower voltage distribution systems

OPGW vs. Underground Fiber

- OPGW utilizes existing transmission infrastructure

- Underground fiber has higher installation costs

- OPGW more vulnerable to weather events

- Underground offers more routing flexibility

OPGW vs. Wireless Communication

- OPGW provides higher bandwidth capacity

- Wireless more susceptible to interference

- OPGW has lower latency

- Wireless easier to deploy in remote areas

Future Trends in OPGW Technology

The OPGW market continues to evolve with several emerging trends:

Higher Fiber Count Designs

Increasing demand for bandwidth drives development of OPGW with:

- 288-fiber and higher configurations

- Space-efficient fiber packaging

- Multi-core fiber technology

Improved Materials

- High-strength, lightweight aluminum alloys

- Corrosion-resistant coatings

- Composite materials for reduced weight

Smart Grid Integration

OPGW plays a key role in smart grid implementation by enabling:

- Phasor measurement unit (PMU) communication

- Distributed automation

- Advanced metering infrastructure backhaul

Conclusion

Optical Ground Wire (OPGW) represents an optimal solution for utilities seeking to combine reliable overhead line protection with robust communication capabilities. Its dual functionality provides cost savings while meeting the growing demand for high-speed data transmission in power networks. As transmission systems evolve toward smarter grids and higher reliability requirements, OPGW will continue to play a vital role in power infrastructure worldwide.

When planning OPGW deployment, careful consideration of technical specifications, installation practices, and maintenance requirements ensures optimal performance throughout the cable's service life. With proper design and implementation, OPGW systems can provide decades of reliable service for both power protection and communication needs.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体