Optical Cables Explained: Practical Design, Installation, and Performance Guide

Optical cables, commonly known as fiber optic cables, are the backbone of modern high-speed communication systems. They enable fast, reliable, and long-distance data transmission for telecommunications, data centers, enterprise networks, and industrial infrastructure. This article focuses on practical knowledge related to optical cables, including their structure, types, installation practices, performance considerations, and real-world applications.

What Optical Cables Are and How They Work

Optical cables transmit data using light signals rather than electrical current. Inside the cable, light pulses travel through a glass or plastic core by total internal reflection. This design allows optical cables to carry significantly more data over longer distances with minimal signal loss compared to copper cables.

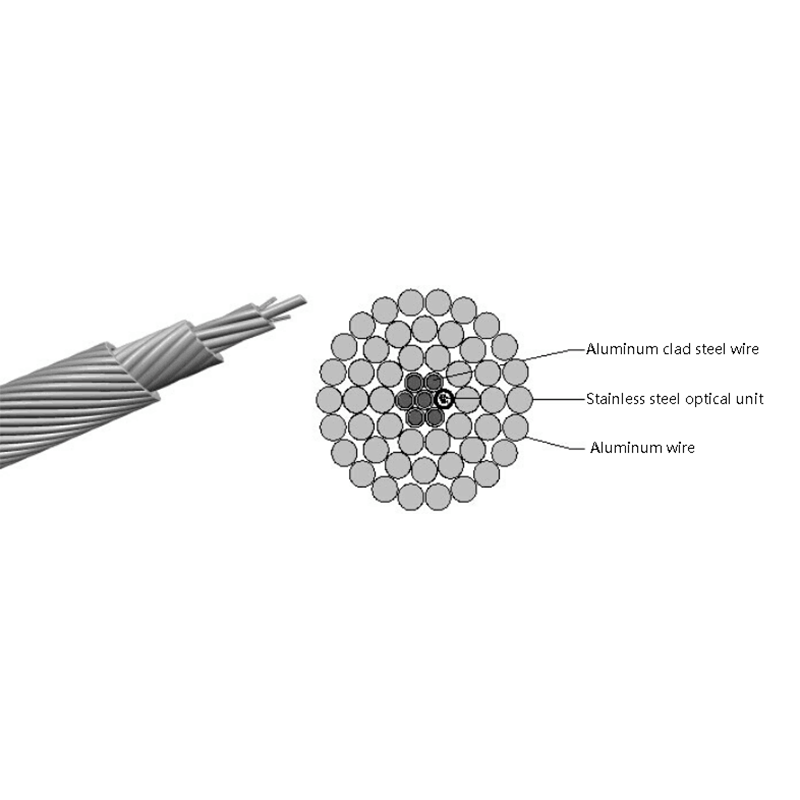

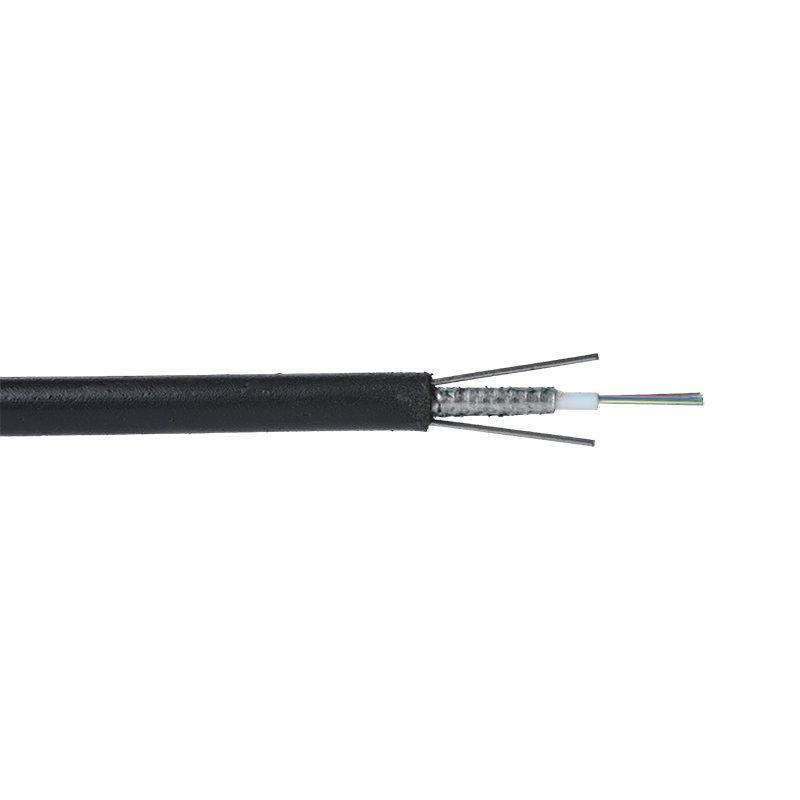

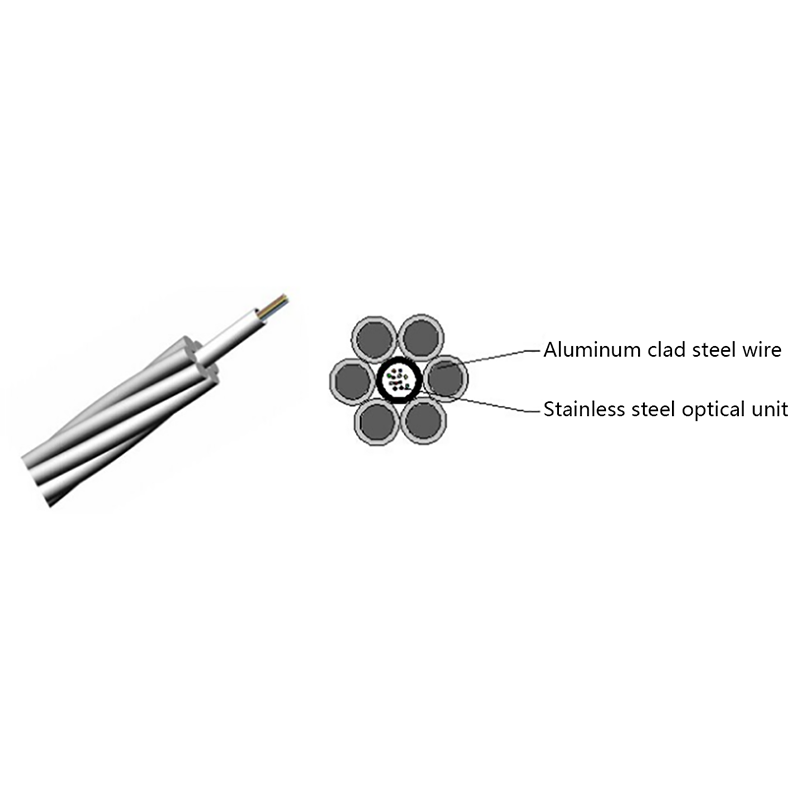

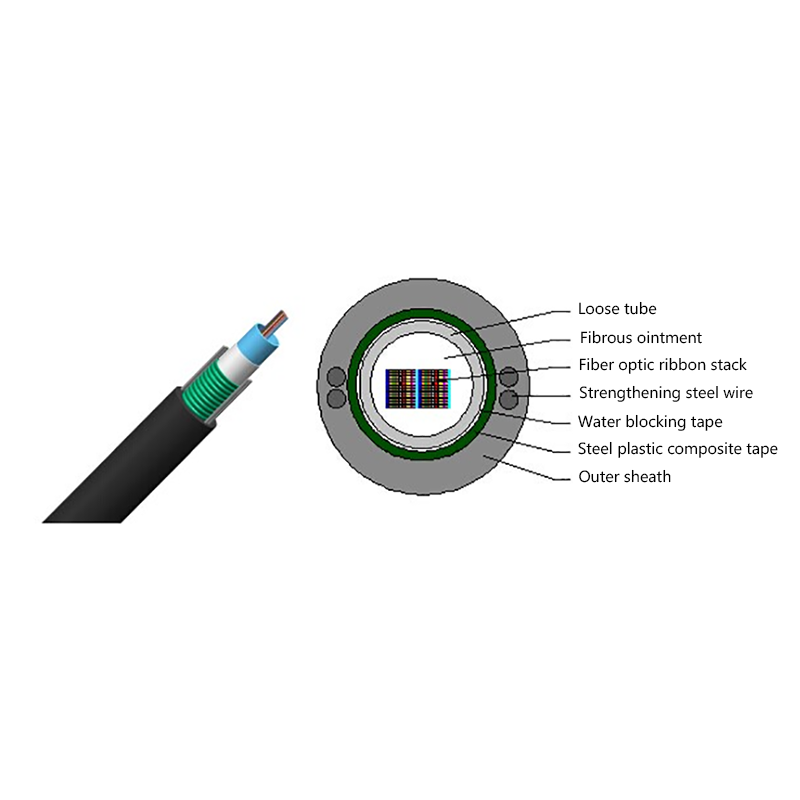

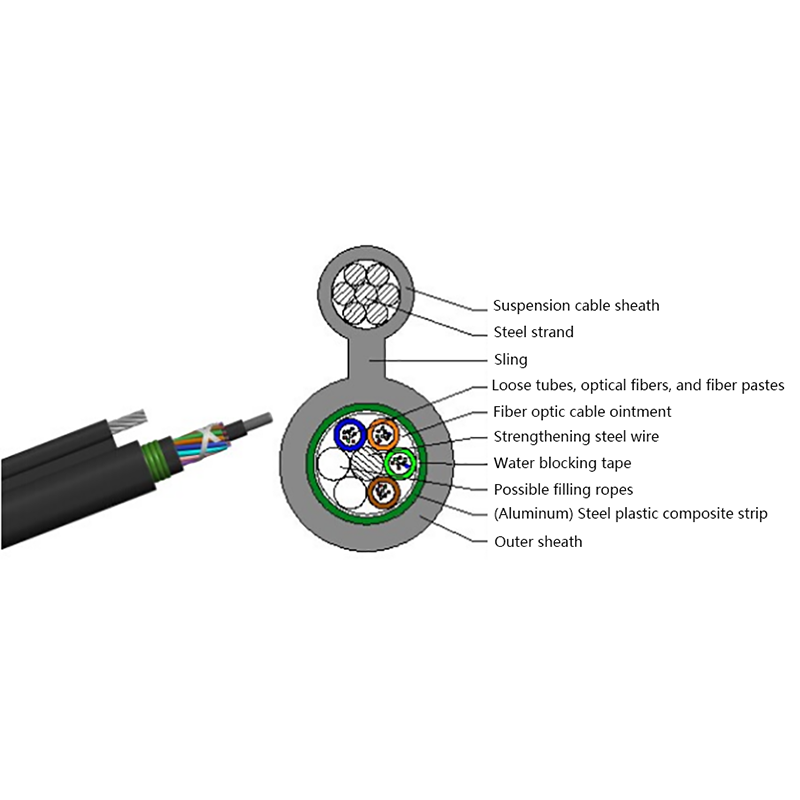

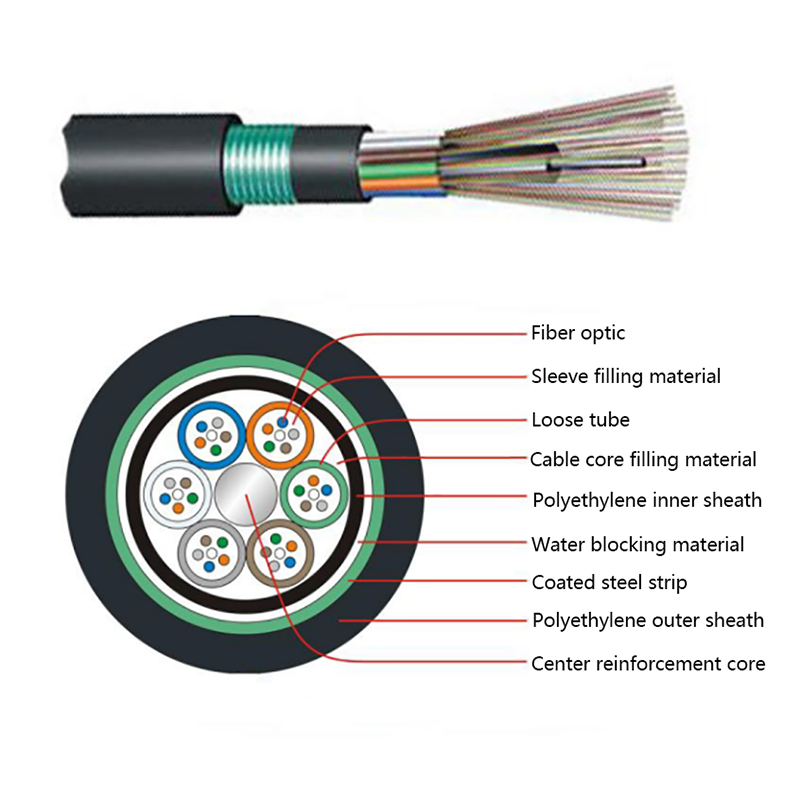

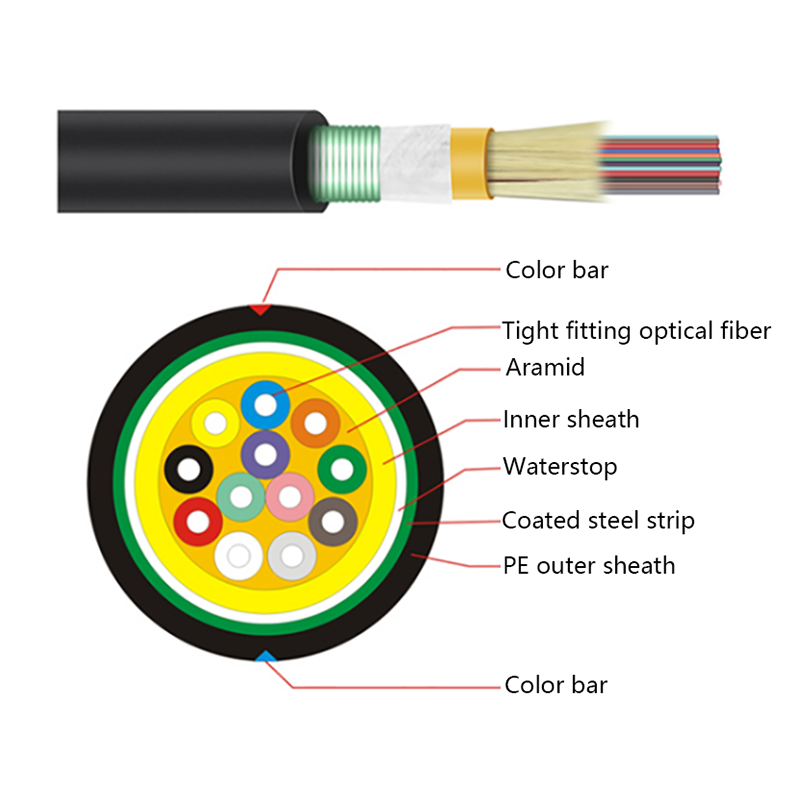

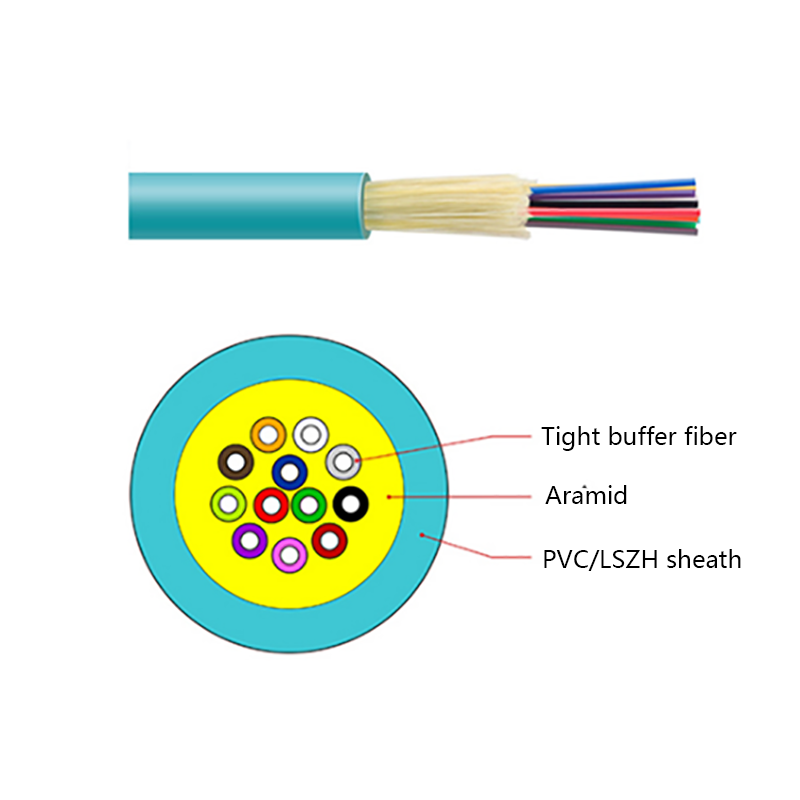

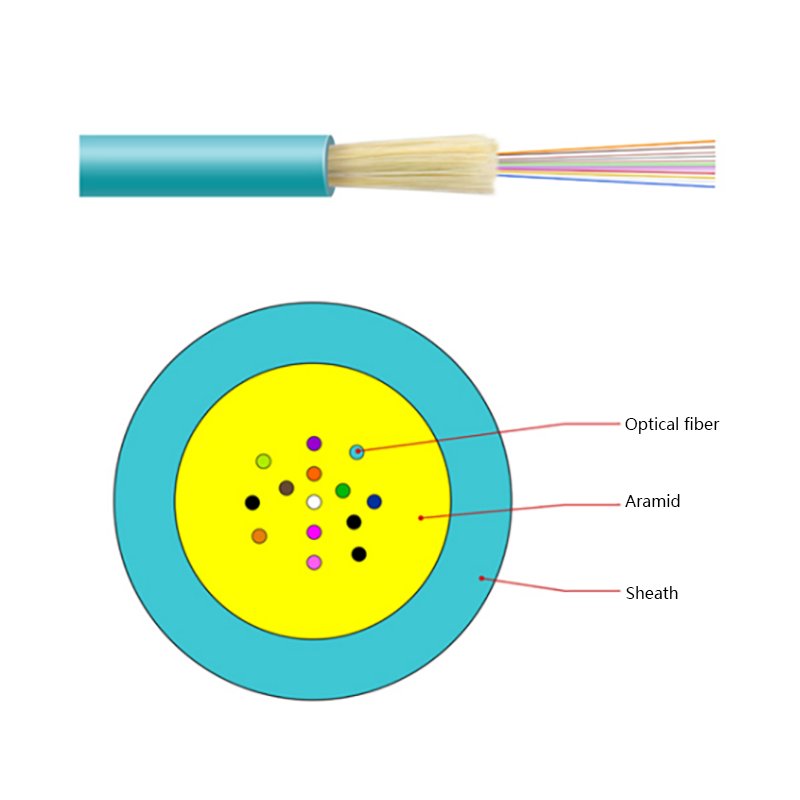

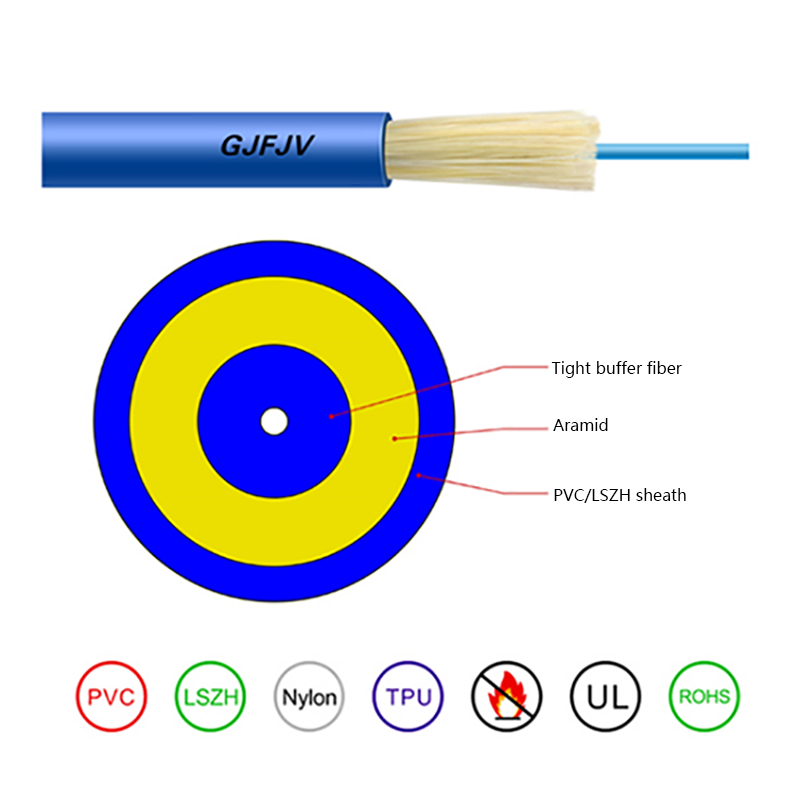

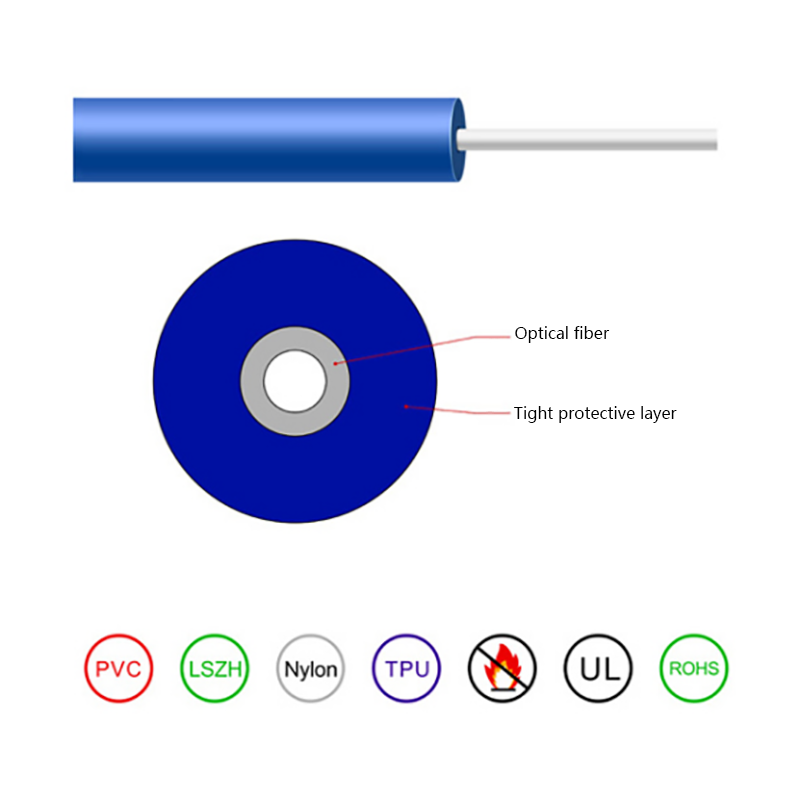

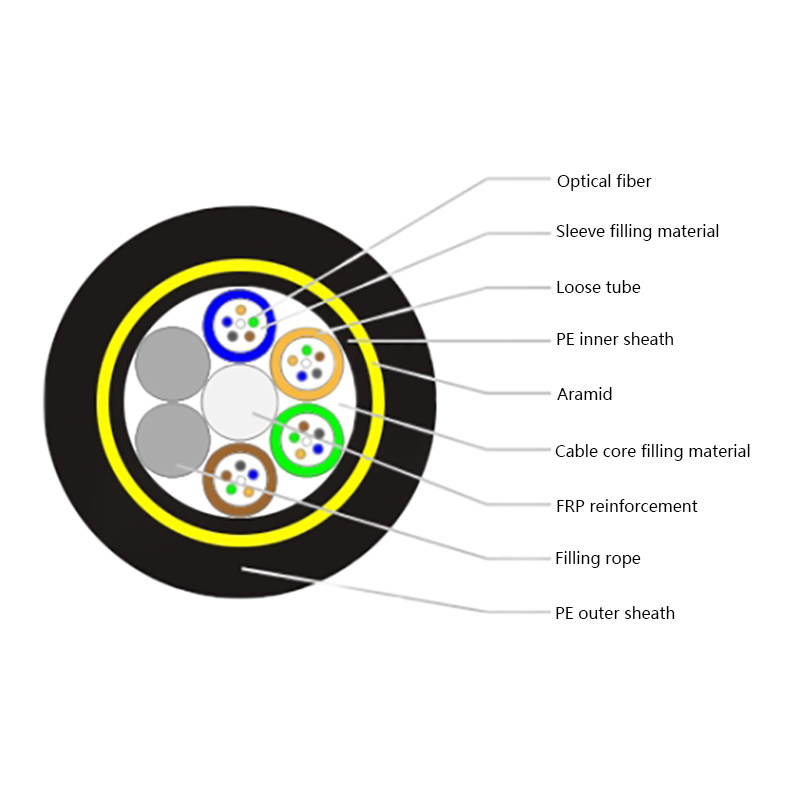

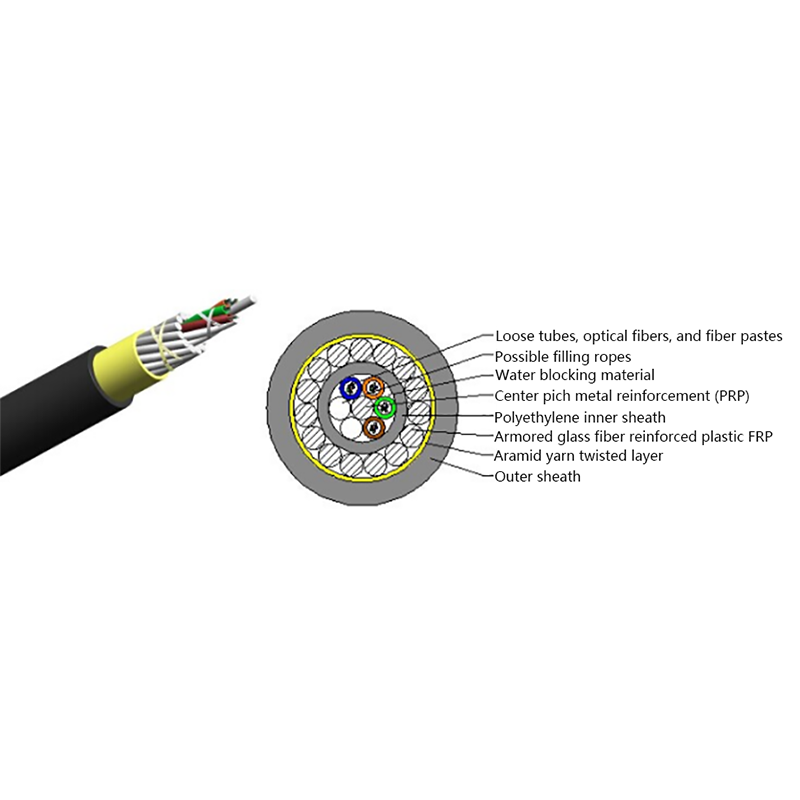

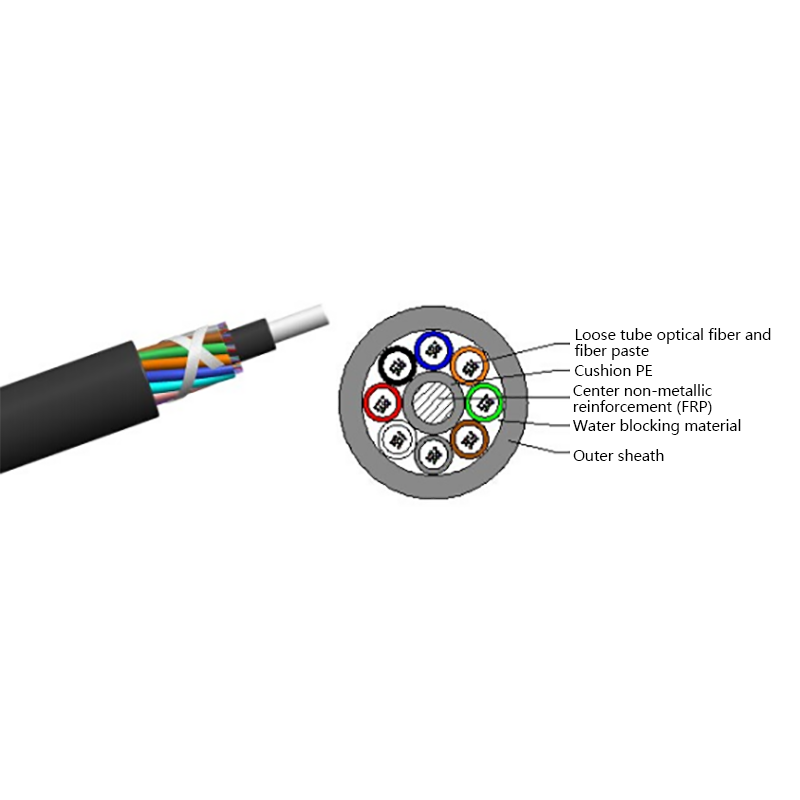

A typical fiber optic cable consists of a core, cladding, buffer coating, strength members, and an outer jacket. Each layer plays a role in protecting the fiber and maintaining signal integrity under physical stress and environmental exposure.

Key Types of Optical Cables

Optical cables are classified based on fiber mode, construction, and intended application. Choosing the correct type is critical for network performance and cost efficiency.

Single Mode Optical Cables

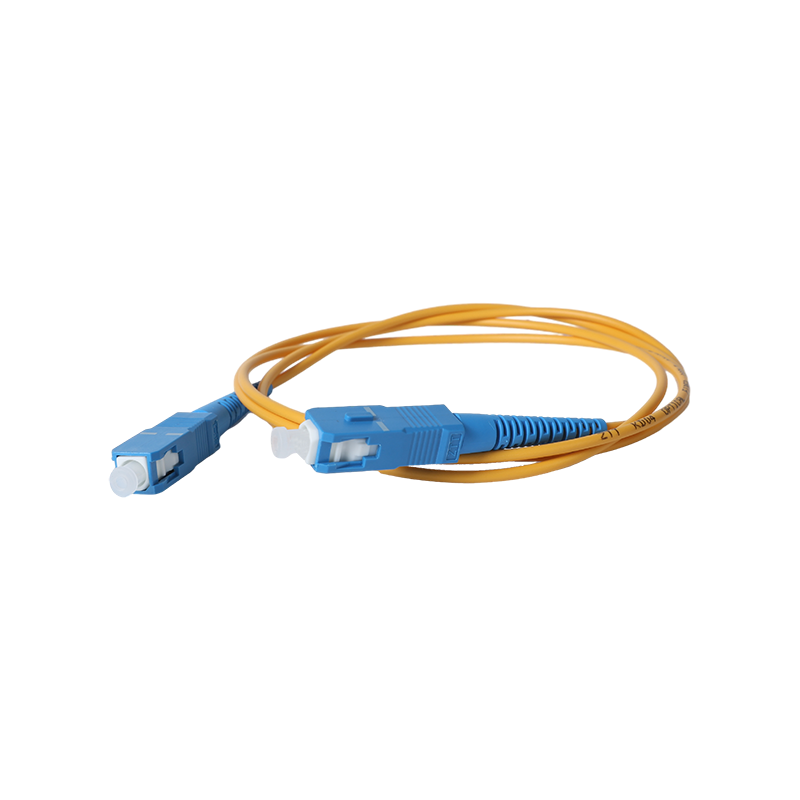

Single mode fiber optic cables use a small core diameter, typically around 9 microns, allowing only one light path. This design minimizes signal dispersion and supports long-distance transmission, making it ideal for telecommunications, backbone networks, and metropolitan area networks.

Multimode Optical Cables

Multimode fiber cables have larger core diameters, usually 50 or 62.5 microns, allowing multiple light paths. They are commonly used for short-distance applications such as data centers, LANs, and enterprise networks where cost and ease of installation are priorities.

Indoor vs Outdoor Optical Cables

Indoor optical cables are designed for controlled environments and often prioritize flexibility and fire resistance. Outdoor optical cables include additional protection against moisture, UV exposure, temperature variation, and mechanical stress.

Common Optical Cable Construction Styles

- Tight-buffered cables, used for indoor installations where flexibility and ease of termination are required.

- Loose-tube cables, commonly used outdoors to protect fibers from temperature-related expansion and contraction.

- Armored optical cables, which include metal layers for added protection against crushing and rodent damage.

Optical Cable Performance Factors

Several technical parameters determine the performance of optical cables. Understanding these factors helps network designers optimize signal quality and system reliability.

| Attenuation | Signal loss per kilometer, measured in dB/km |

| Bandwidth | Maximum data transmission capacity |

| Dispersion | Pulse spreading over distance |

| Operating Wavelength | Common ranges include 850nm, 1310nm, and 1550nm |

Installation Best Practices for Optical Cables

Proper installation is critical to maintaining the performance and longevity of optical cables. Poor handling can lead to microbends, macrobends, or fiber breaks that degrade signal quality.

- Observe minimum bend radius requirements during routing and termination.

- Avoid excessive pulling force by using proper cable pulling tools and lubricants.

- Use appropriate cable management systems to prevent stress at connection points.

Testing and Maintenance of Optical Cables

Routine testing ensures that optical cables continue to meet performance requirements. Common testing methods include optical time-domain reflectometer (OTDR) testing and insertion loss testing. These tools help identify faults such as breaks, splices with high loss, or connector contamination.

Maintenance activities should include regular inspection of connectors, cleaning of fiber end faces, and verification of cable routes to ensure no physical damage has occurred over time.

Practical Applications of Optical Cables

Optical cables are used across a wide range of industries due to their high bandwidth, security, and reliability.

- Telecommunications networks for long-haul and metropolitan connectivity.

- Data centers requiring high-speed interconnections between servers and storage systems.

- Industrial environments where electromagnetic interference resistance is essential.

Selecting the Right Optical Cable for Your Project

Choosing the correct optical cable involves evaluating distance requirements, data rates, environmental conditions, and budget constraints. For long-distance, high-capacity links, single mode fiber is typically preferred. For shorter distances within buildings or campuses, multimode fiber may offer a more cost-effective solution.

Environmental factors such as moisture exposure, temperature range, and mechanical stress should guide the choice between indoor, outdoor, or armored optical cables. Matching the cable design to the application ensures reliable performance and reduces maintenance costs.

By understanding optical cable construction, performance characteristics, and installation best practices, network planners and technicians can build robust fiber optic systems that support current needs and future expansion.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体