Optical Cables: Practical Design, Installation, and Maintenance Guide

Understanding Optical Cable Structure

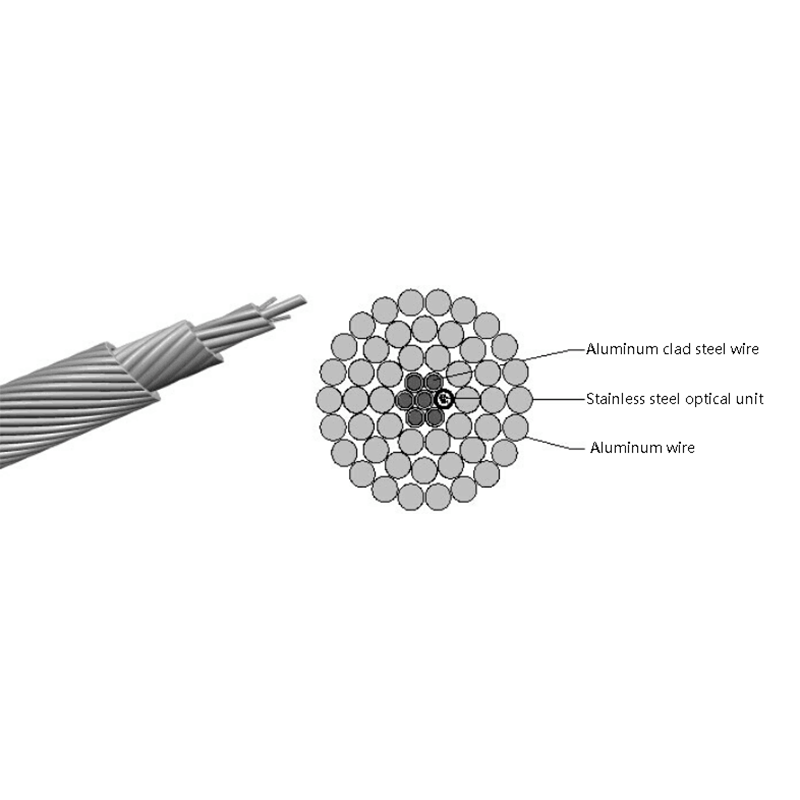

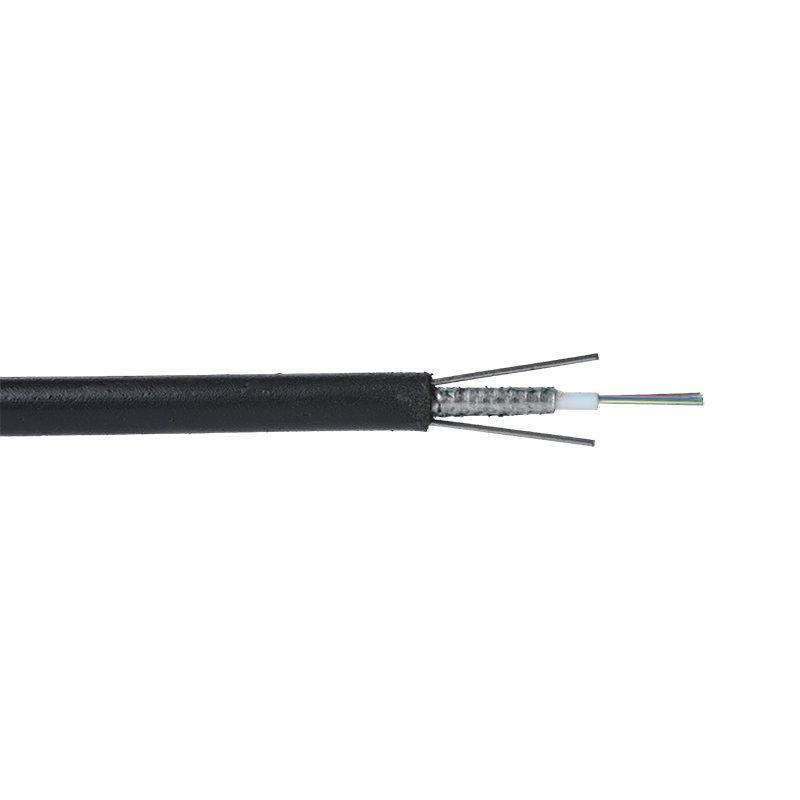

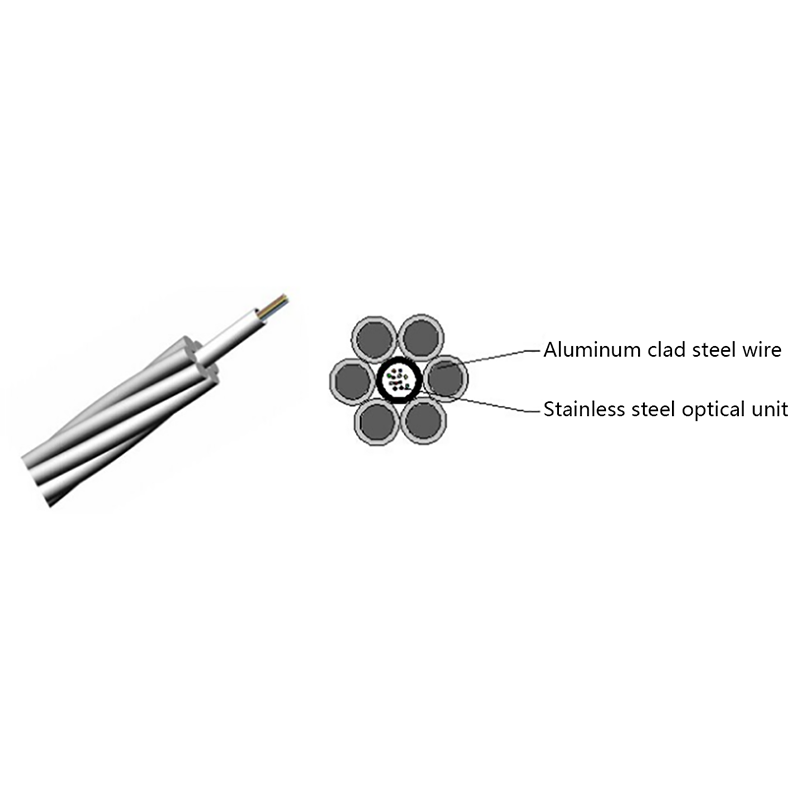

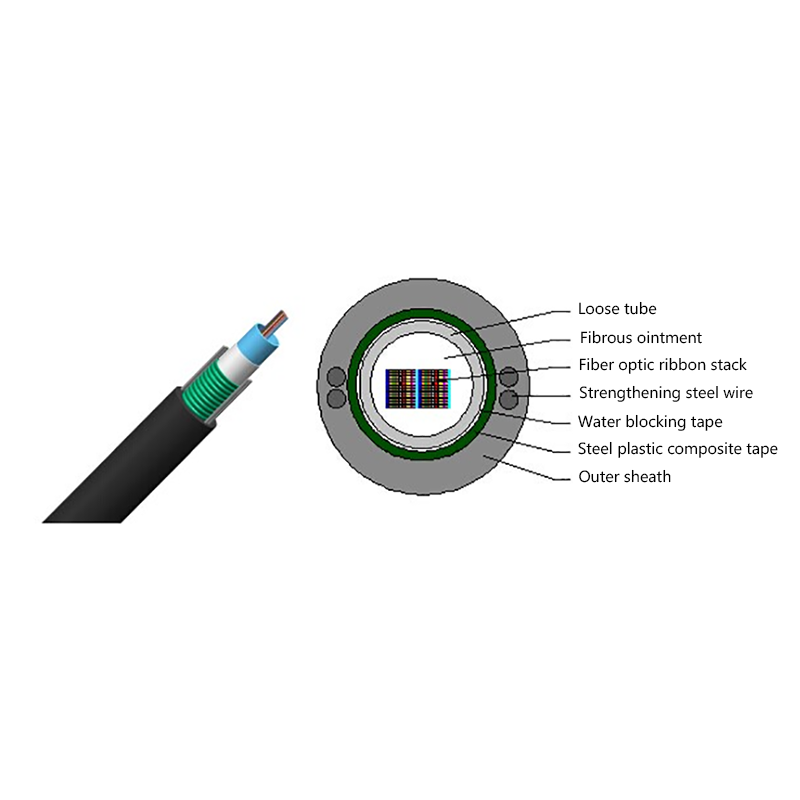

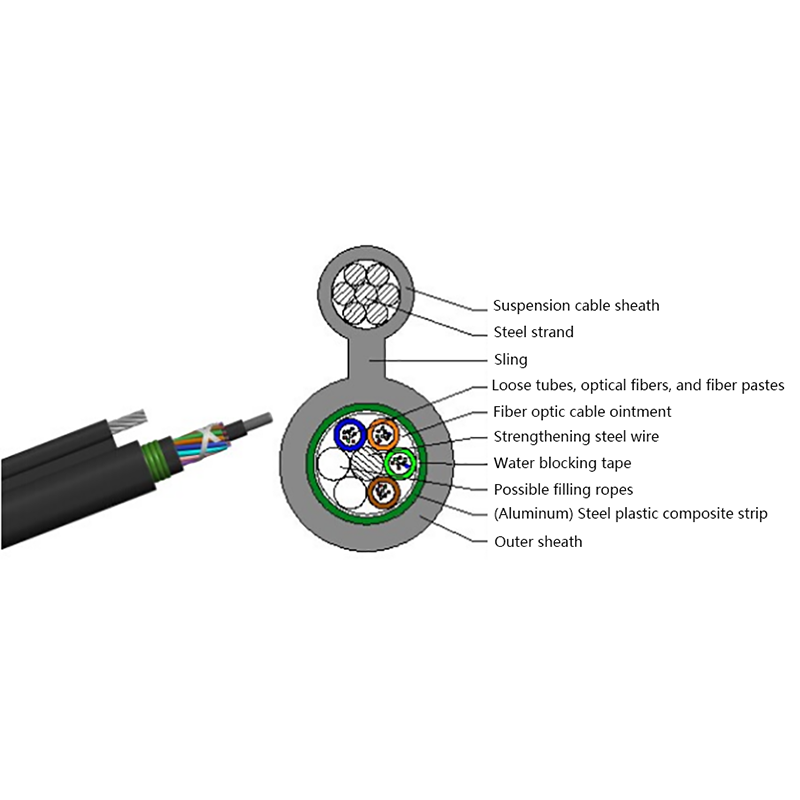

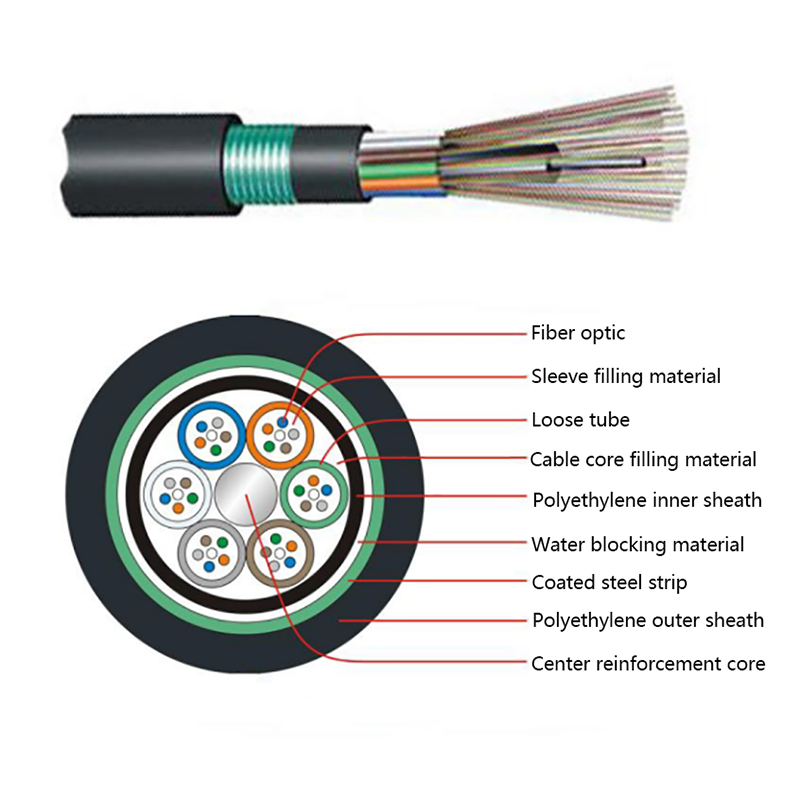

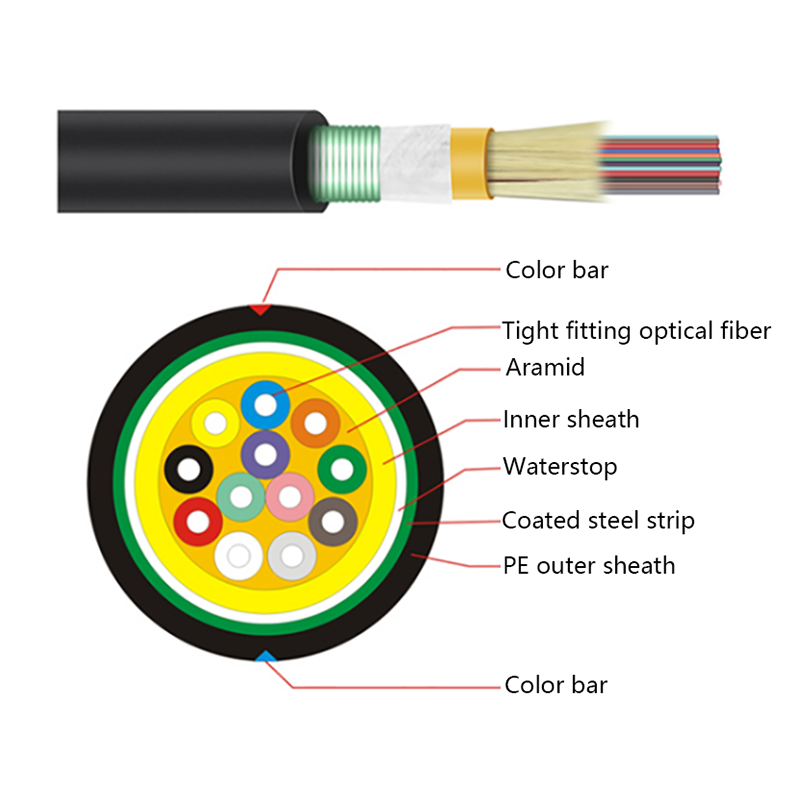

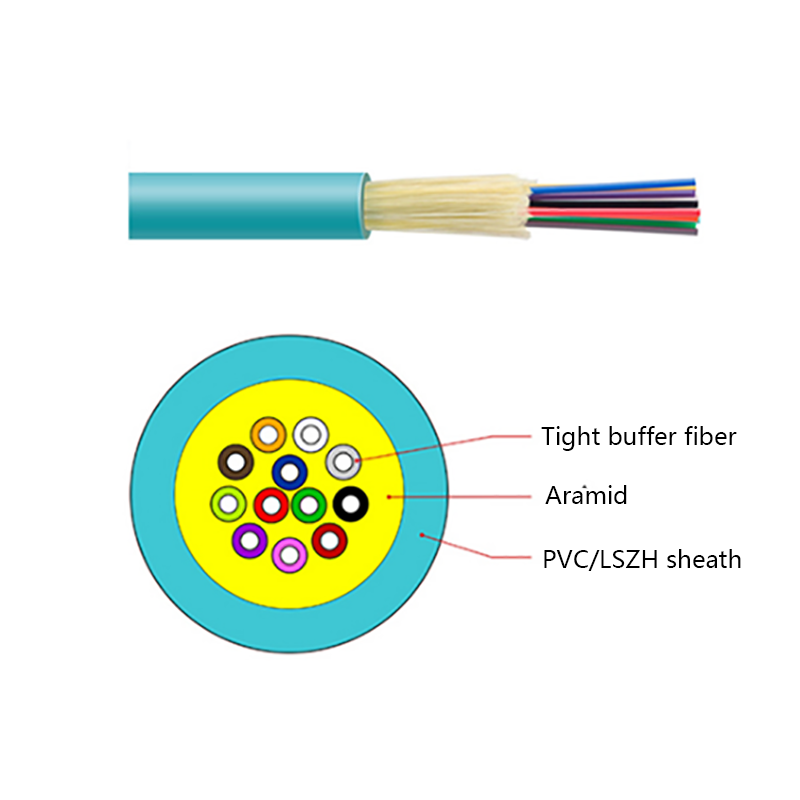

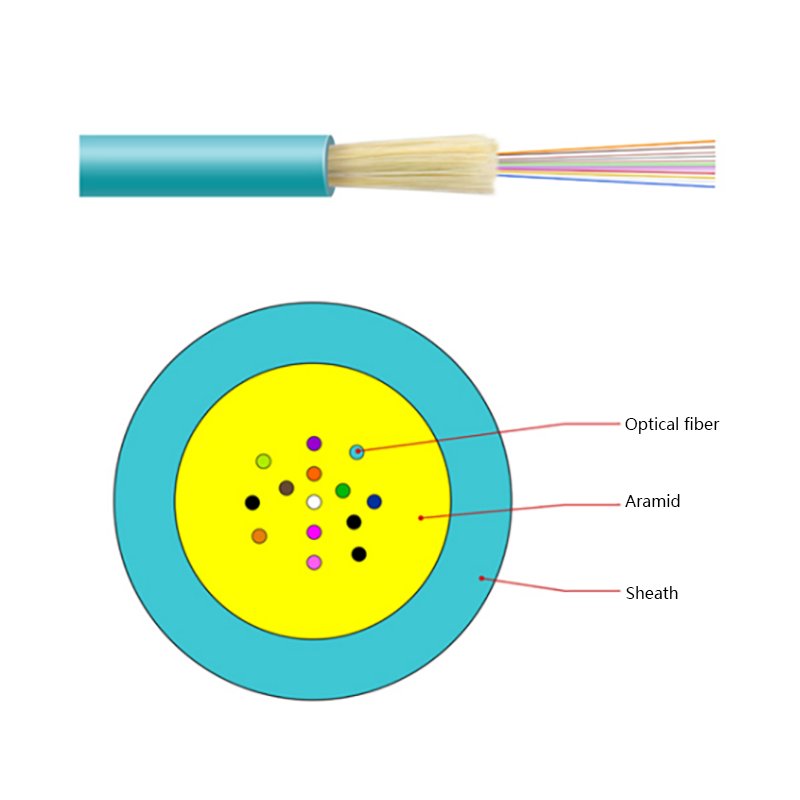

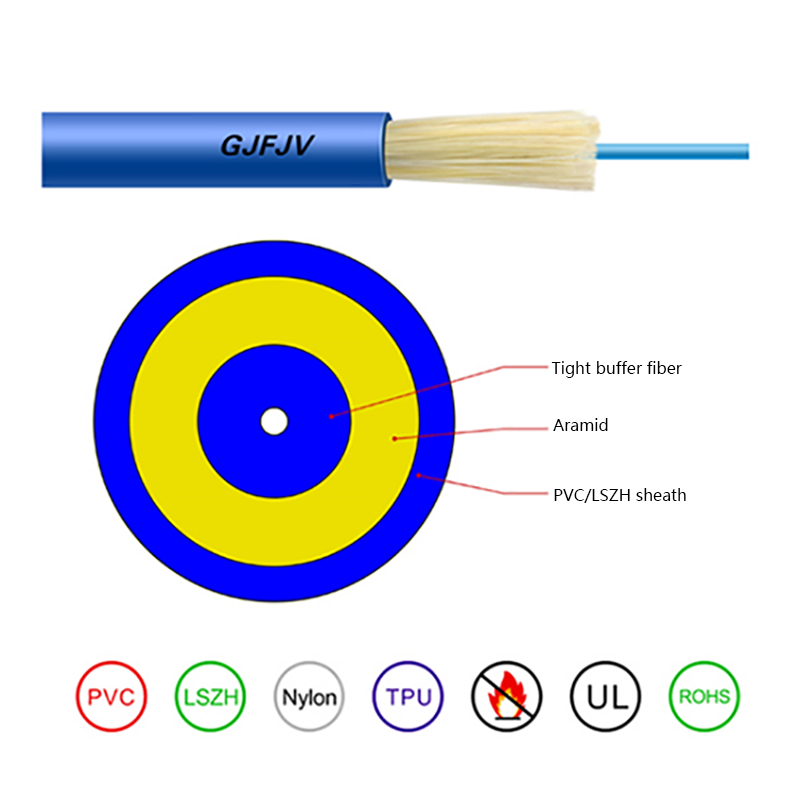

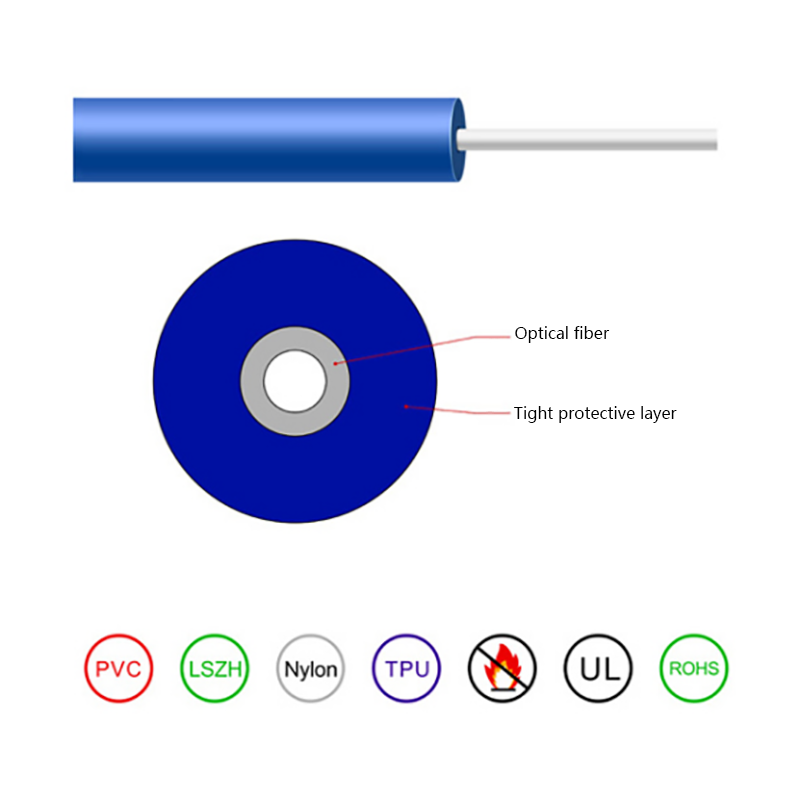

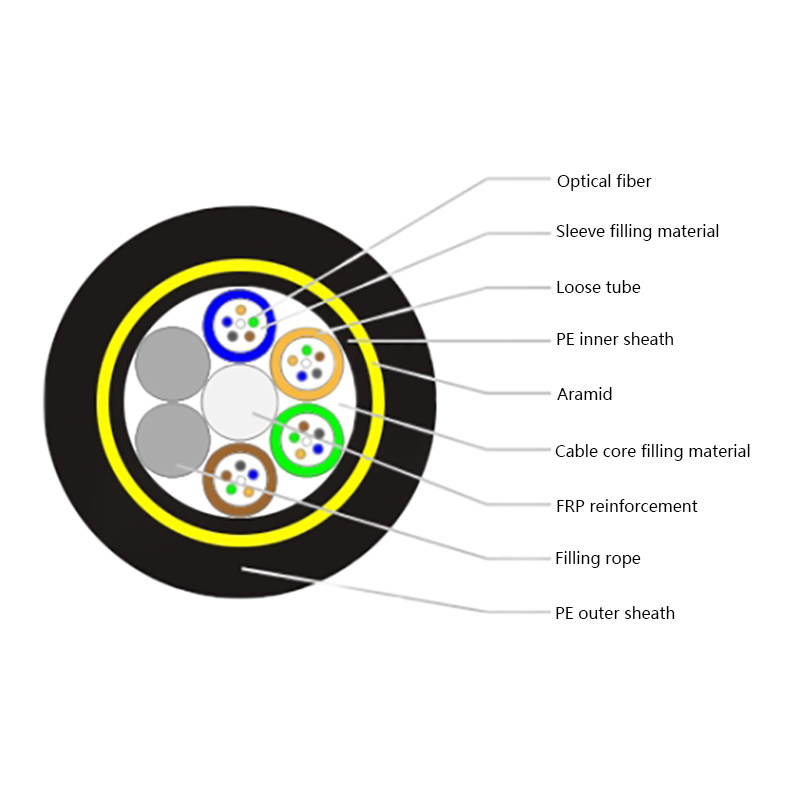

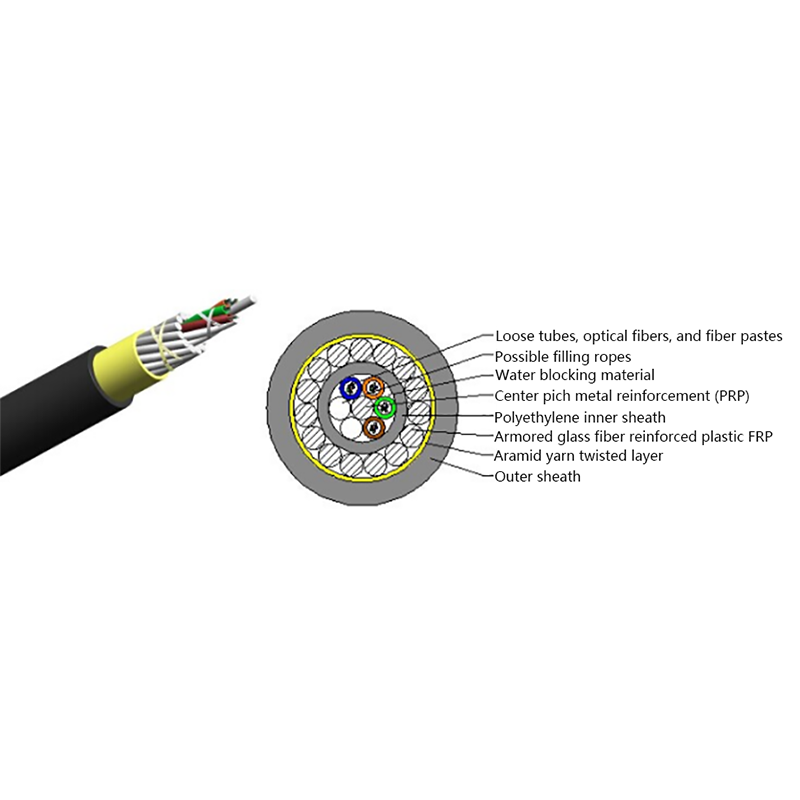

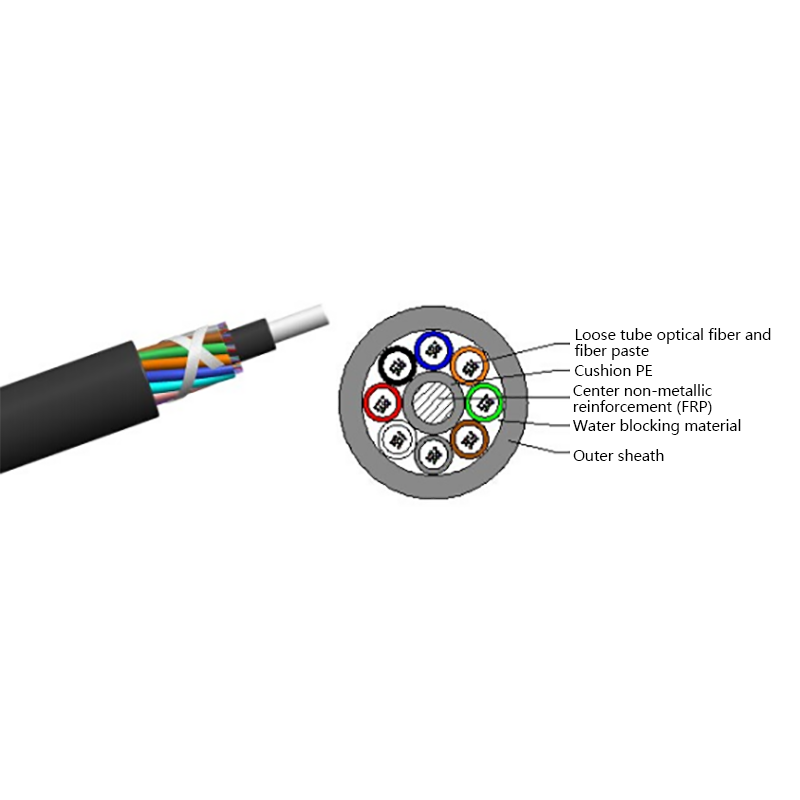

Optical cables are designed to transmit data as light pulses through glass or plastic fibers. At the core of each fiber is the core itself, surrounded by cladding that reflects light inward. This structure minimizes signal loss and allows data to travel long distances at high speeds. Around the fiber, protective layers such as buffer coatings, strength members, and outer jackets are added to handle environmental and mechanical stress.

In practical deployments, understanding the internal structure helps installers select appropriate handling methods and avoid damage. For example, tight-buffered cables are easier to terminate indoors, while loose-tube designs are more tolerant of temperature variations outdoors.

Single-Mode and Multi-Mode Optical Cables

Optical cables are commonly classified as single-mode or multi-mode. Single-mode fibers have a smaller core diameter, allowing only one light path. This makes them suitable for long-distance communication, such as backbone networks and telecommunications infrastructure.

Multi-mode fibers have a larger core and allow multiple light paths, making them cost-effective for short-distance applications like data centers and local area networks. Choosing between the two depends on distance requirements, bandwidth needs, and budget constraints.

- Single-mode: long distance, higher precision, lower attenuation

- Multi-mode: shorter distance, easier alignment, lower equipment cost

Common Optical Cable Jacket Types

The outer jacket of an optical cable plays a crucial role in protecting fibers from environmental damage. Indoor cables often use flame-retardant jackets, while outdoor cables focus on moisture resistance, UV protection, and mechanical durability.

| Jacket Type | Typical Use |

| PVC | Indoor installations |

| LSZH | Public buildings, safety-focused areas |

| PE | Outdoor and underground deployments |

Installation Best Practices

Proper installation is essential to ensure optical cable performance and longevity. Excessive bending, pulling, or twisting can cause micro-cracks in fibers, leading to signal loss over time. Installers should always respect the manufacturer’s minimum bend radius and maximum pulling tension.

Cable Routing and Handling

When routing cables through conduits or trays, smooth paths reduce friction and stress. Using cable lubricants and pulling socks can help distribute tension evenly. Labeling cables during installation also simplifies future maintenance and troubleshooting.

Connector and Termination Considerations

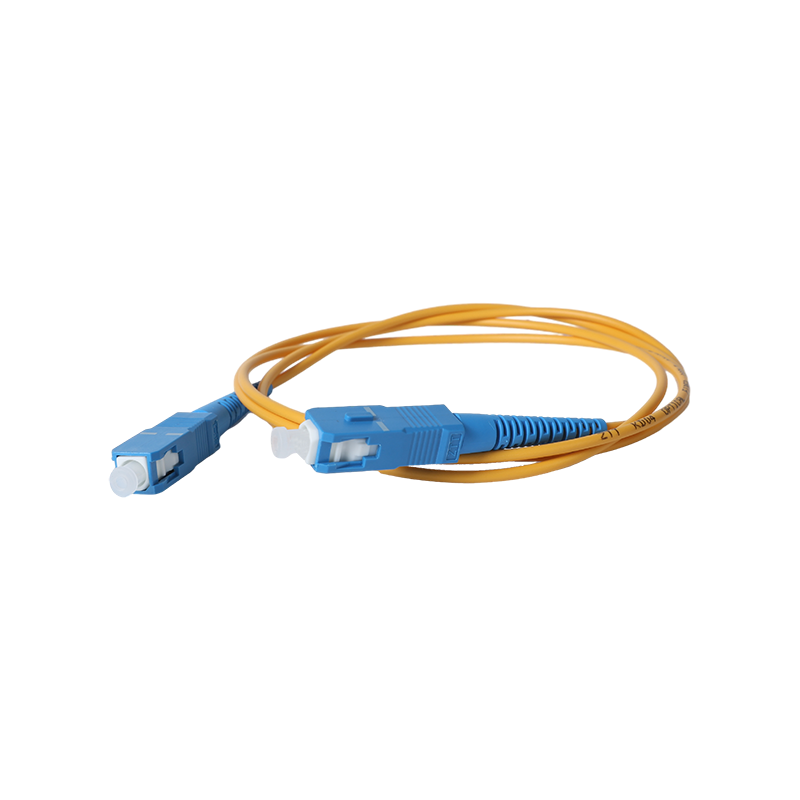

Optical cable termination involves attaching connectors to fiber ends. Common connector types include SC, LC, and ST, each suited to different equipment and density requirements. Precision during termination is critical, as poor polishing or alignment can introduce reflection and insertion loss.

Field termination kits and pre-terminated cables are both viable options. Pre-terminated solutions reduce installation time but require accurate length planning, while field termination offers flexibility at the cost of skilled labor.

Testing and Performance Verification

After installation, optical cables should be tested to confirm signal integrity. Common tools include optical power meters, light sources, and OTDRs. These tests help identify excessive attenuation, breaks, or poor splices before the network goes live.

- Continuity testing ensures fibers are correctly connected

- Loss testing verifies acceptable attenuation levels

- OTDR testing locates faults along the cable length

Maintenance and Troubleshooting

Optical cables generally require minimal maintenance, but periodic inspections help prevent unexpected failures. Checking for physical damage, ensuring connectors remain clean, and monitoring performance metrics can extend system life.

When issues arise, common causes include dirty connectors, accidental bends, or damaged jackets. Cleaning connectors with proper tools and replacing compromised sections often resolves performance degradation without full cable replacement.

Practical Selection Tips for Real Projects

Selecting the right optical cable requires balancing technical requirements with practical constraints. Consider installation environment, expected lifespan, scalability, and local regulations. Consulting system designers and reviewing project documentation helps avoid costly changes later.

By focusing on appropriate cable types, careful installation, and proper testing, optical cable systems can deliver reliable, high-speed communication for many years with minimal intervention.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体