What Do Fiber Optic Cables Look Like? Structure & Appearance Guide

Physical Appearance of Fiber Optic Cables

Fiber optic cables are surprisingly thin and delicate-looking, typically ranging from 250 micrometers to several millimeters in diameter depending on their protective layers. The core—where light actually travels—is incredibly fine, measuring just 8-10 micrometers for single-mode fiber and 50-62.5 micrometers for multimode fiber, which is thinner than a human hair. When you see a fiber optic cable, you're looking at multiple protective layers wrapped around this microscopic glass or plastic core, giving it a colorful, flexible appearance similar to electrical wiring but noticeably more lightweight.

The outer jacket of fiber optic cables comes in various bright colors—commonly yellow, orange, aqua, or blue—that serve as quick visual identifiers for cable type and application. These cables are remarkably flexible and can be bent around corners with a minimum bend radius, though they require more careful handling than traditional copper cables due to the glass fibers inside.

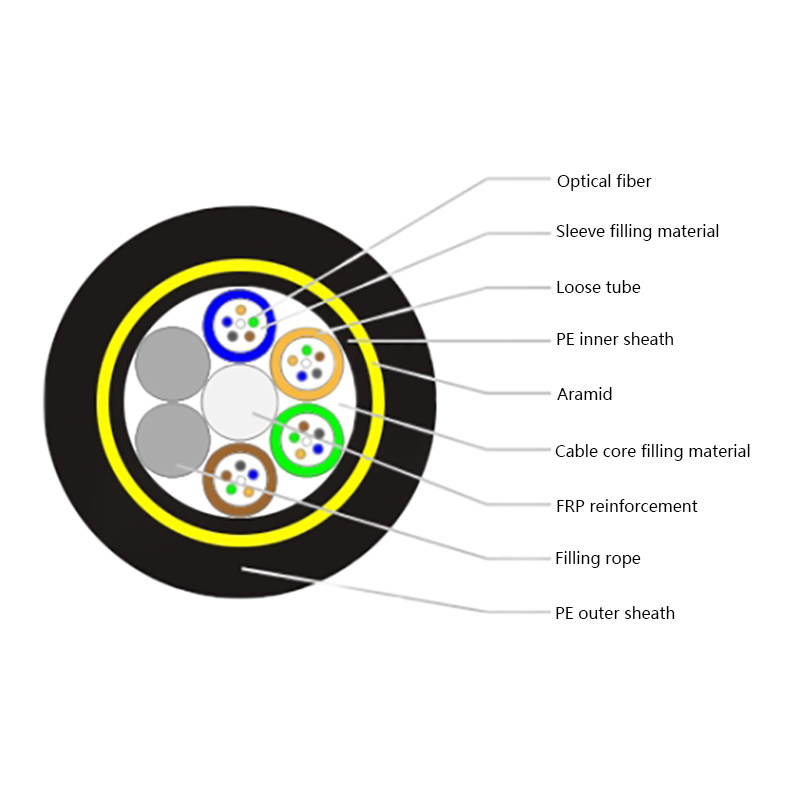

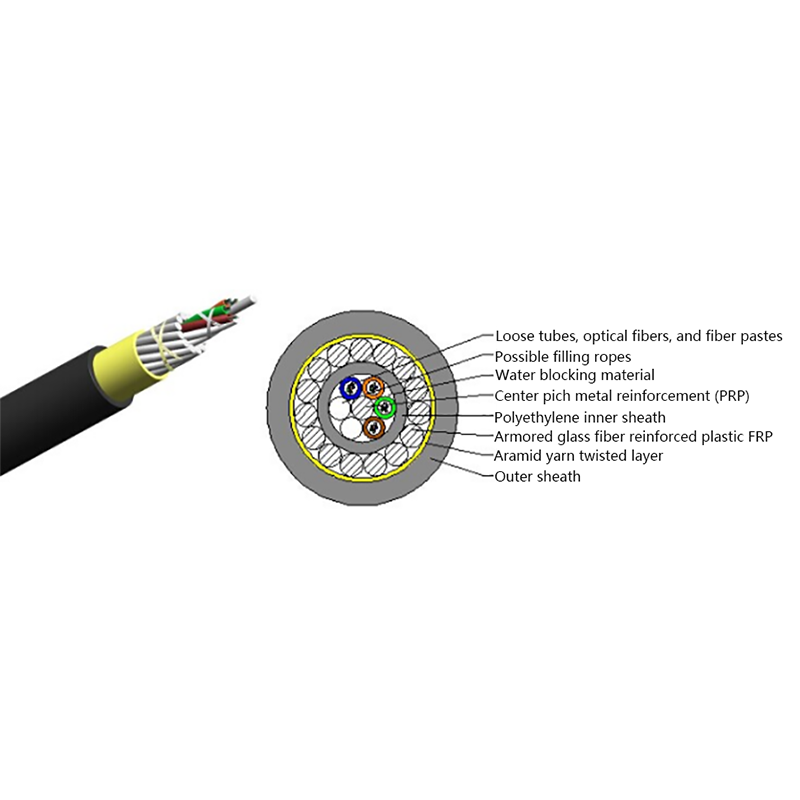

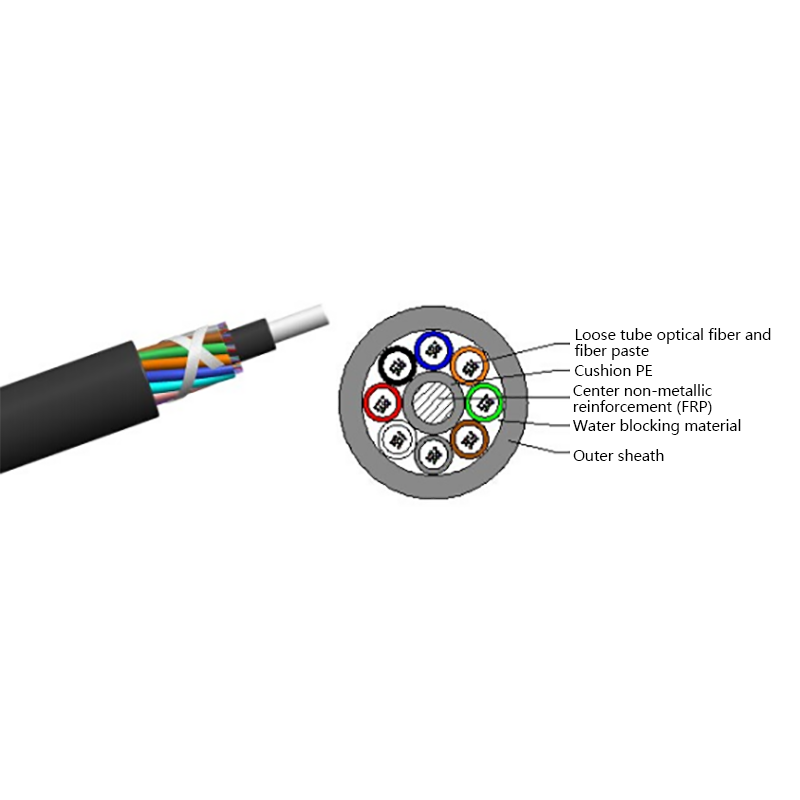

Layer-by-Layer Structure You Can See

Understanding what you're looking at requires knowing the distinct layers that make up a fiber optic cable, each visible when the cable is stripped or cross-sectioned:

The Core and Cladding

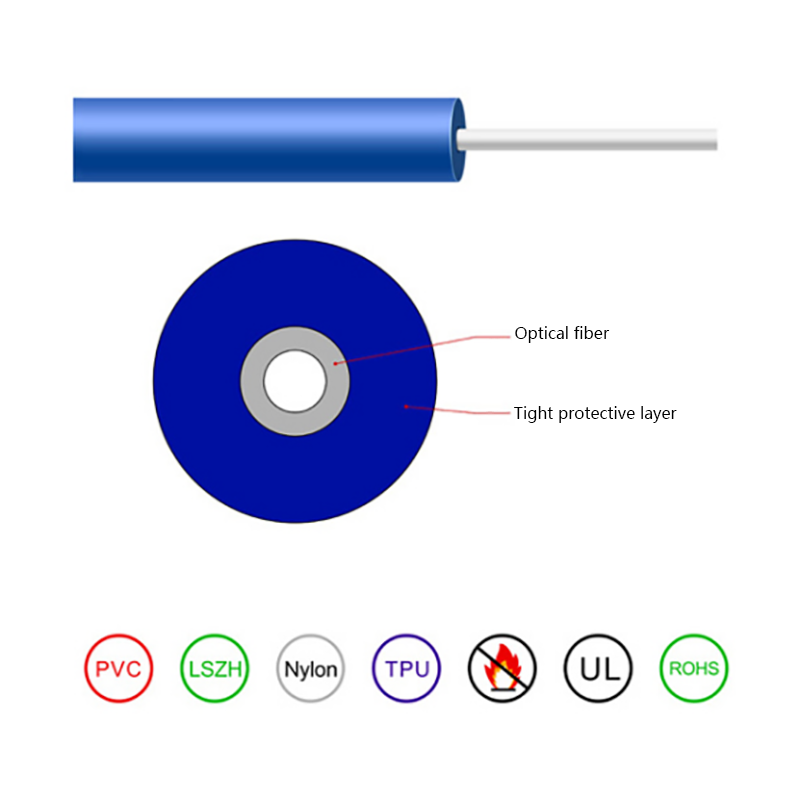

At the very center is the core—an ultra-thin strand of glass or plastic that appears almost invisible to the naked eye. Surrounding this is the cladding, a layer of glass with a lower refractive index that measures approximately 125 micrometers in total diameter. When exposed, these layers look like a hair-thin, clear or slightly frosted glass filament. Under proper lighting, you might see light glowing from the end of an active fiber, demonstrating its light-transmitting properties.

Buffer Coating

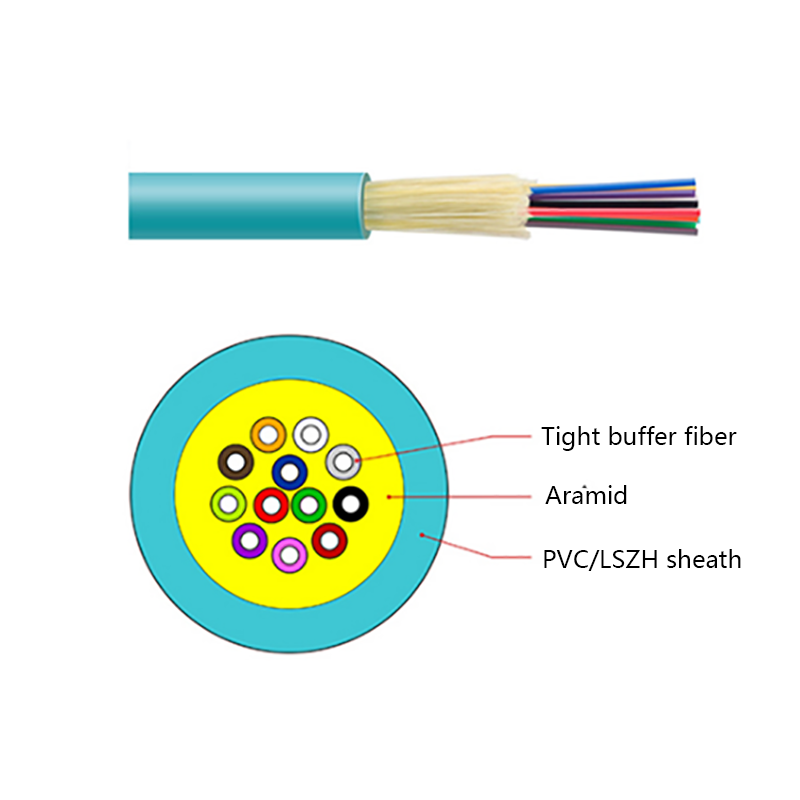

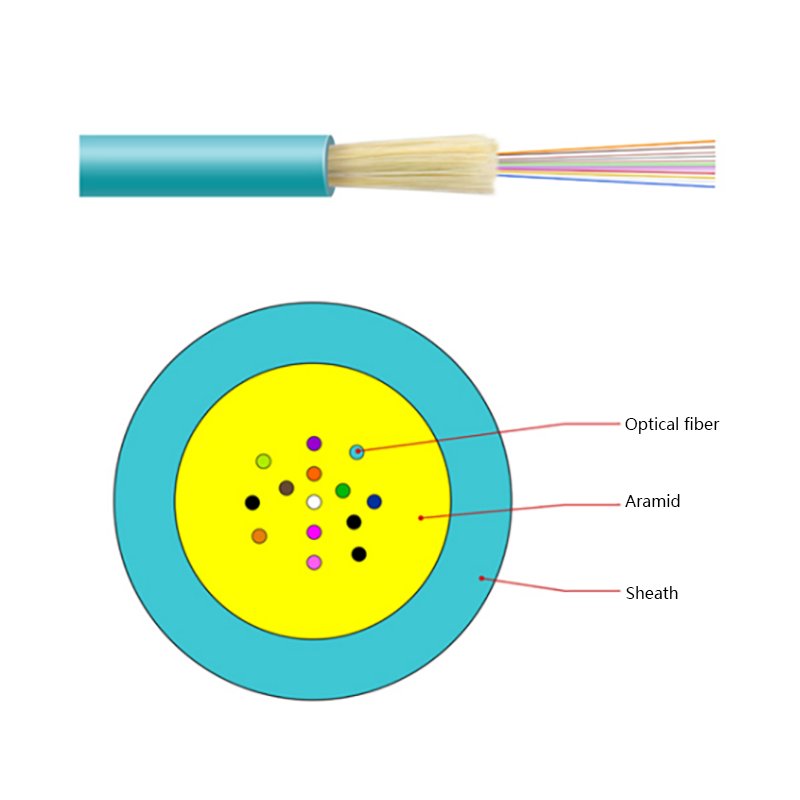

The first visible protective layer is the buffer coating, a colored plastic layer (typically 250-900 micrometers) that makes individual fibers identifiable. This coating gives each fiber strand a distinctive color—you'll see combinations like blue, orange, green, brown, slate, white, red, black, yellow, violet, rose, and aqua in 12-fiber ribbon configurations.

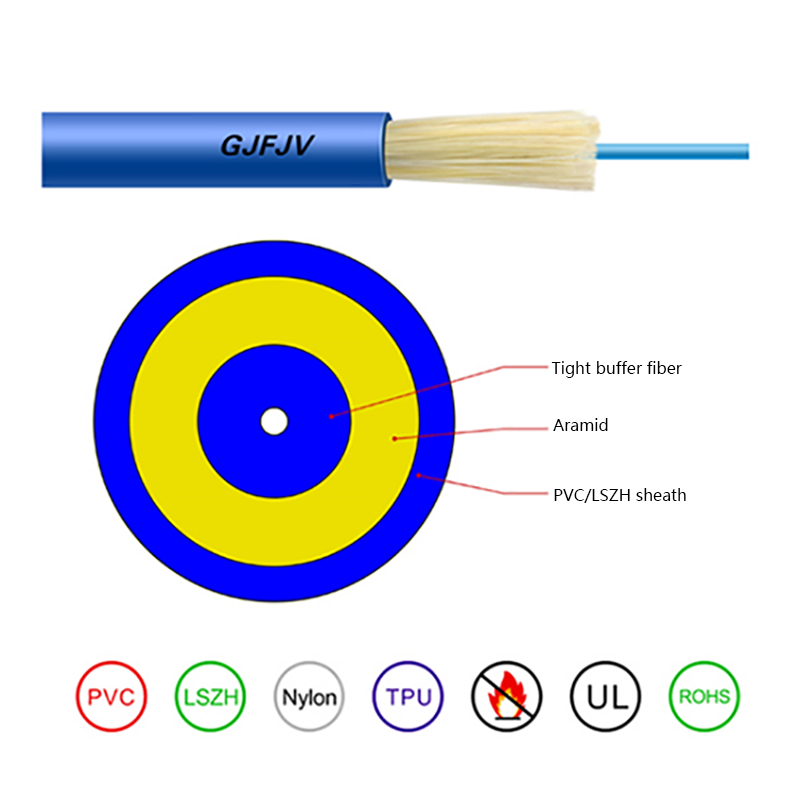

Strength Members and Outer Jacket

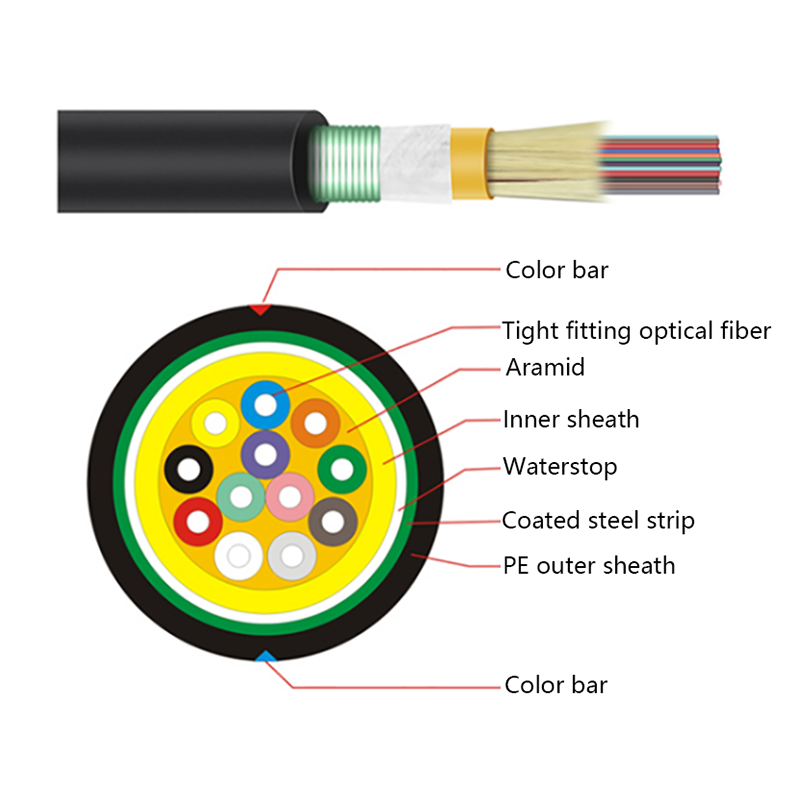

Surrounding the buffered fibers, you'll find aramid yarn (similar to Kevlar) or fiberglass rods that appear as white or yellow fibrous material, providing tensile strength. The outermost layer is the jacket, a thick plastic sheath typically 2-3 millimeters thick for indoor cables and up to 15 millimeters or more for outdoor/armored cables. This jacket determines the cable's overall appearance and color.

Common Cable Types and Their Visual Characteristics

| Cable Type | Typical Color | Diameter | Visual Features |

|---|---|---|---|

| Single-Mode (OS2) | Yellow | 3mm | Thin, bright yellow jacket, very flexible |

| Multimode OM1/OM2 | Orange | 3mm | Orange jacket, slightly thicker core |

| Multimode OM3/OM4 | Aqua | 3mm | Aqua/cyan jacket for laser-optimized fiber |

| Multimode OM5 | Lime Green | 3mm | Bright lime green for wideband fiber |

| Outdoor Armored | Black | 10-15mm | Thick, rigid black jacket, corrugated metal visible when cut |

| Tactical/Military | Black/OD Green | 5-8mm | Rugged, matte finish, extremely durable construction |

Indoor plenum-rated cables often have a matte finish and may be marked "OFNP" (Optical Fiber Nonconductive Plenum) on the jacket, while riser-rated cables display "OFNR" markings. These text markings are typically printed every two feet along the cable length, providing important identification information.

Connector Appearances That Identify Cable Types

The connectors attached to fiber optic cables provide immediate visual identification of cable type and application. These precisely engineered components have distinct appearances:

- LC connectors are small, square-shaped connectors roughly the size of a standard RJ45 Ethernet connector, featuring a snap-in latch mechanism and often found in high-density applications

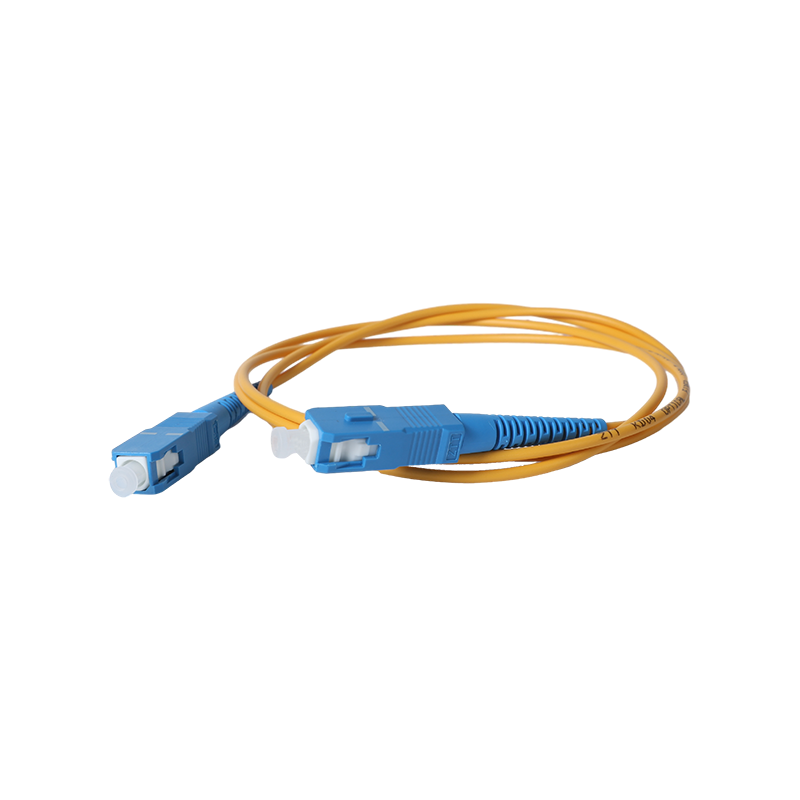

- SC connectors have a larger, rectangular push-pull design with a distinctive snap-in coupling, making them easy to install and remove

- ST connectors feature a round, bayonet-style twist-lock mechanism similar to BNC connectors, commonly seen in older installations

- MTP/MPO connectors are rectangular multi-fiber connectors that can house 12 or 24 fibers in a single connector body, appearing bulkier than single-fiber types

Connector bodies follow the same color-coding: beige for multimode OM1/OM2, aqua for OM3/OM4, lime green for OM5, and blue for single-mode. The ferrule—the small ceramic or plastic piece at the connector's tip—is where the fiber ends are polished flush, appearing as a tiny dot of glass when inspected closely.

Differences Between Indoor and Outdoor Cables

The environment determines cable construction, creating visually distinct products:

Indoor Cables

Indoor fiber cables are relatively lightweight and flexible, with smooth PVC or LSZH (Low Smoke Zero Halogen) jackets. They measure approximately 2-4 millimeters in diameter for simplex cables and up to 8 millimeters for 12-fiber distribution cables. The jackets are typically bright and smooth, designed for easy routing through building infrastructure. Tight-buffered designs mean the protective coating is directly on the fiber, creating a stiffer but more durable indoor cable.

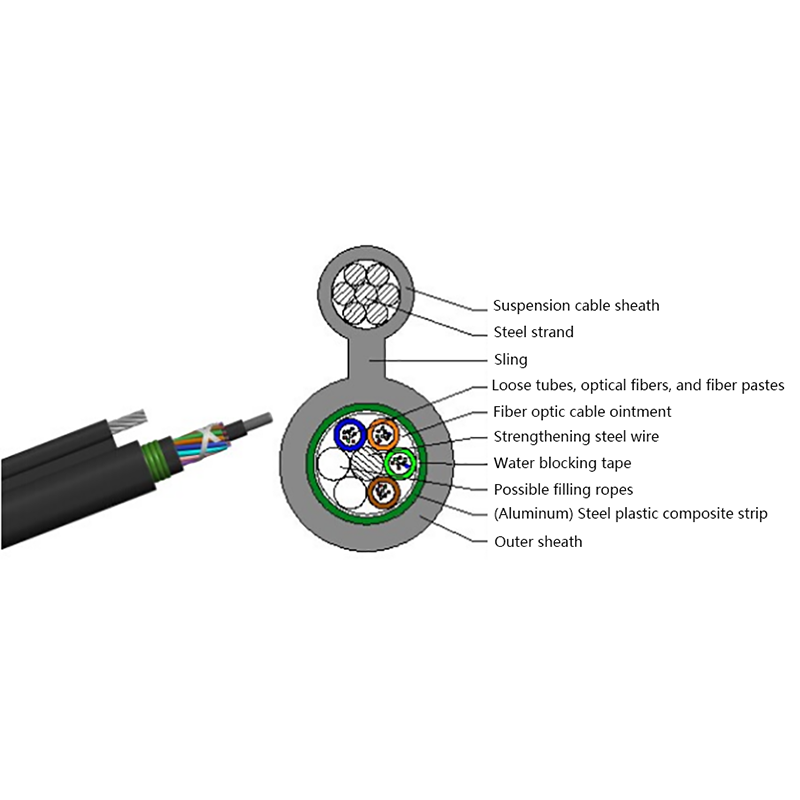

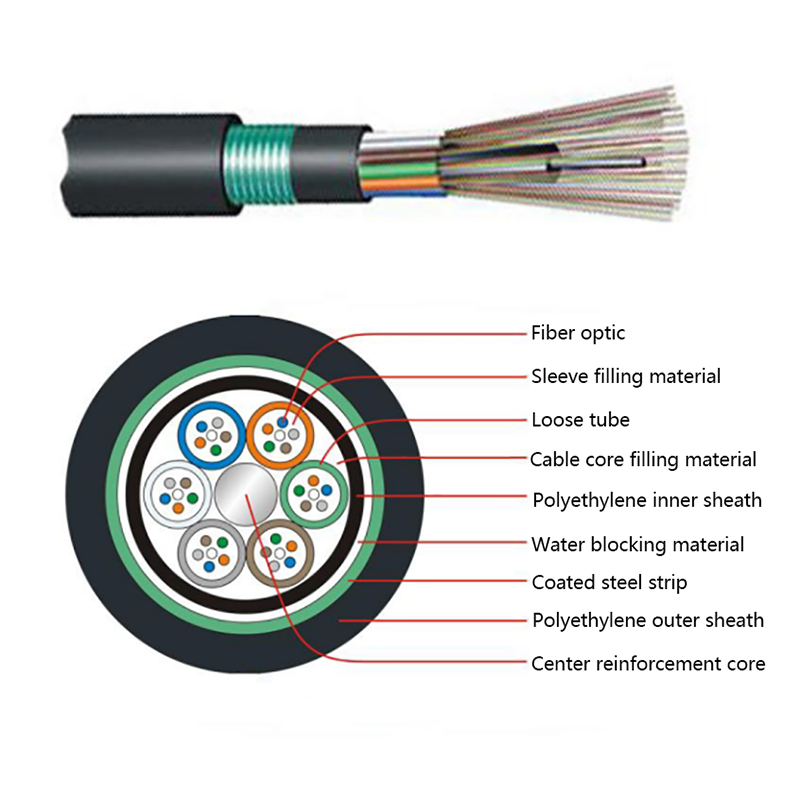

Outdoor Cables

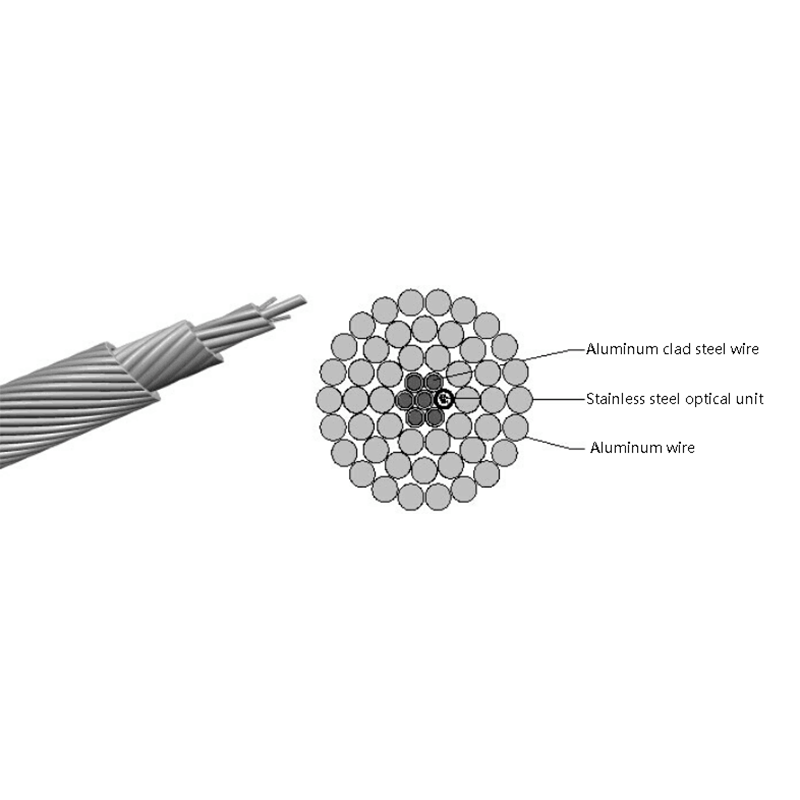

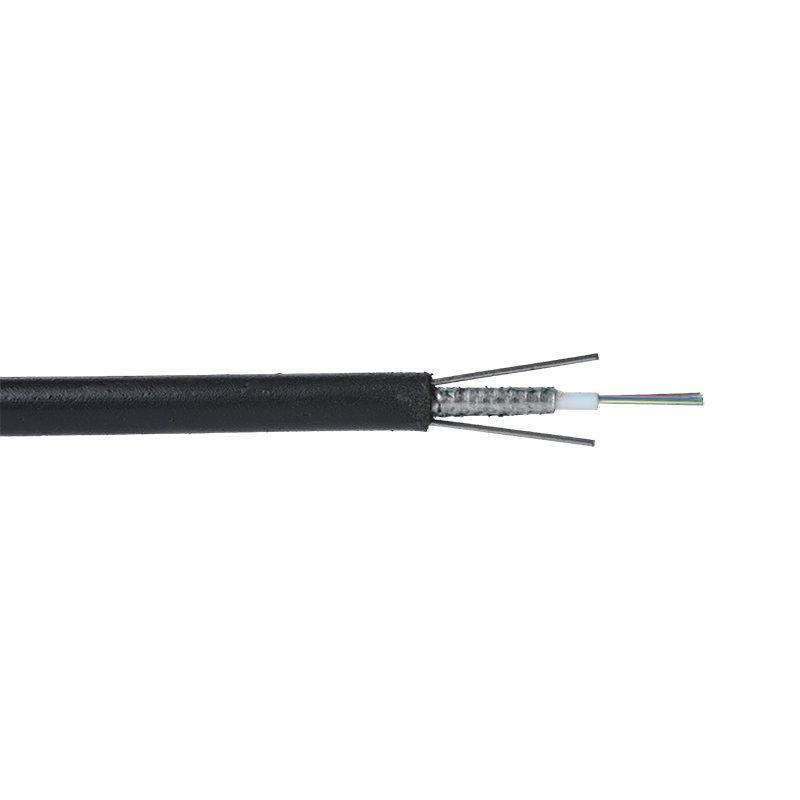

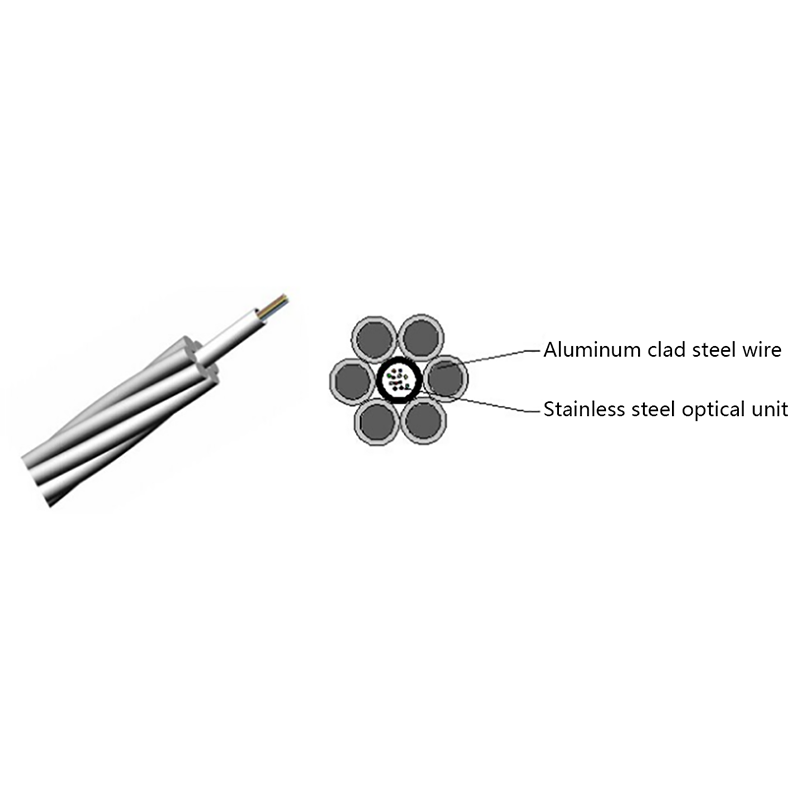

Outdoor cables appear significantly more robust, with black UV-resistant polyethylene jackets that can be 10-20 millimeters thick. Armored versions include a corrugated metal layer visible when the cable is cut, providing protection against rodents and mechanical damage. Loose-tube designs house fibers in gel-filled or dry-filled tubes, giving the cable a bulkier cross-section. Direct burial cables may include additional flooding compounds visible as gel when opened, designed to prevent water ingress.

Aerial cables often incorporate steel messenger wires or integrated strength members that create a distinctive figure-8 cross-section, easily recognizable during installation. Some outdoor cables reach 25 millimeters or more in diameter when containing 144+ fibers with full environmental protection.

What You See When Light Travels Through Fiber

One of the most distinctive visual characteristics of fiber optic cable is how it transmits light. When an active fiber is exposed or tested, you can observe:

- A bright red or infrared glow at the fiber end when using a visual fault locator (VFL), which emits 650nm red light at 1mW power

- Light scattered along breaks or bends in the fiber, making fault locations visible as bright spots in the cable jacket

- Fiber cores appearing to glow when illuminated, demonstrating the principle of total internal reflection

- Invisible infrared light at 1310nm or 1550nm wavelengths during actual data transmission, requiring special detection equipment to observe

This light transmission capability makes fiber optic cables unique among networking cables—while copper cables show no external indication of data flow, active fiber cables can visibly demonstrate signal presence during testing.

Identifying Fiber Count by Cable Appearance

The number of fibers inside a cable directly affects its size and appearance:

- Simplex cables contain one fiber strand and measure approximately 2-3mm in diameter with a round or oval cross-section

- Duplex cables have two fibers in a zip-cord configuration (figure-8 shape) or round jacket, measuring 3-5mm across

- Distribution cables with 6-12 fibers appear as round cables 5-8mm in diameter with individually buffered and color-coded fibers inside

- Backbone cables containing 24-144+ fibers can be 15-25mm in diameter with multiple tube layers or ribbon structures visible when opened

The jacket typically displays printed specifications every few feet, including fiber count, cable type (e.g., "12F SM OS2"), manufacturer, and date code. For example, you might see markings like "CORNING 12-FIBER SINGLE-MODE OS2 OFNP" printed along the yellow jacket.

Specialized Cable Designs and Their Appearances

Beyond standard installations, specialized fiber optic cables have unique visual characteristics suited to specific applications:

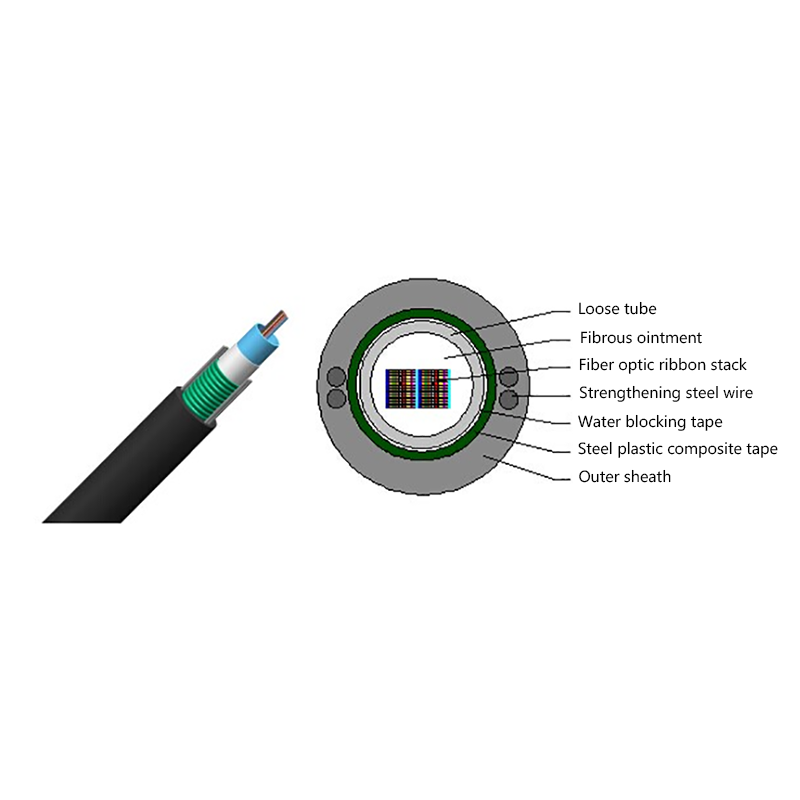

Ribbon Cables

When opened, ribbon cables reveal fibers arranged side-by-side in a flat ribbon structure, with 12 or 24 fibers fused together in a thin matrix. This configuration allows for mass fusion splicing and creates a distinctive appearance when cross-sectioned, looking like a colorful ribbon of tiny glass threads.

Breakout Cables

Breakout designs feature individually jacketed fibers bundled together within an outer sheath. When this outer layer is removed, you see multiple mini-cables each 2-3mm in diameter, color-coded and ready for individual termination. This creates a cable that fans out into multiple legs, resembling a multi-conductor electrical cable.

Armored and Tactical Cables

Military-grade tactical cables incorporate interlocking metal armor or aramid braid visible through transparent sections, providing crush resistance up to 1000 pounds per inch. These cables appear substantially more rugged, with matte black or olive drab finishes and reinforced connector boots. The cross-section reveals multiple protective layers including metal shielding that gives the cable significant weight and rigidity.

Underwater and Submarine Cables

Submarine fiber cables are massive structures, often 20-50mm in diameter, incorporating steel armor, copper power conductors for repeaters, and multiple layers of waterproofing. Their cross-sections reveal complex engineering with central fiber bundles surrounded by strength members, power conductors, and thick polyethylene insulation layers.

Visual Inspection and Quality Indicators

Professional fiber optic installers look for specific visual indicators when assessing cable quality and condition:

- Jacket integrity: The outer sheath should show no cracks, kinks, or compression marks. Damage appears as white stress marks, cuts, or deformed sections that compromise internal fiber protection.

- Connector cleanliness: Ferrule end-faces should appear pristine when viewed through a microscope at 200x magnification, showing no scratches, debris, or contamination. Even a 1-micrometer particle can cause significant signal loss.

- Bend radius compliance: Cables should maintain gentle curves with no sharp bends. The minimum bend radius is typically 10 times the cable diameter under load and 20 times when unloaded. Visible kinks indicate potential fiber damage.

- Color consistency: Jacket colors should be uniform without fading, which could indicate UV exposure degrading outdoor cables. Indoor cable discoloration suggests environmental issues.

When examining stripped fiber, the glass should appear completely transparent and uniform. Any cloudiness, discoloration, or surface irregularities indicate compromised fiber that will affect performance. Professional-grade microscope inspection reveals the polished ferrule surface, which should show a smooth, scratch-free finish with the fiber core centered perfectly.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体