How Do Optoelectronic Composite Cables Enhance Communication Reliability in Industrial Settings?

In modern industrial environments, reliable communication networks are essential for smooth operations, safety, and real-time monitoring. As industries increasingly integrate automation, sensors, and data-driven decision-making, the demand for high-speed, interference-free, and durable communication systems continues to rise. Optoelectronic Composite Cables have emerged as one of the most effective solutions to meet these needs, combining the advantages of optical fiber and electrical conductors within a single integrated cable.

1. Understanding Optoelectronic Composite Cables

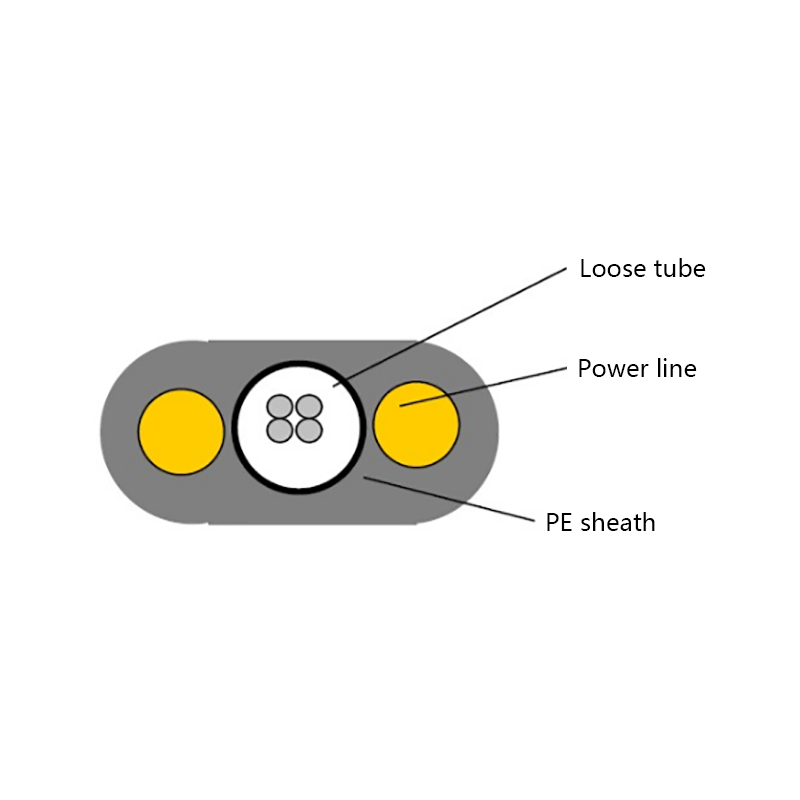

Optoelectronic Composite Cables are hybrid cables that integrate optical fibers for data transmission with electrical conductors for power delivery or signal control. This combination allows both high-speed communication and power supply to occur through one cable assembly.

The optical fiber portion of the cable transmits data using light signals, offering high bandwidth and immunity to electromagnetic interference (EMI). Meanwhile, the electrical conductors deliver low-voltage power or analog/digital control signals to connected devices such as sensors, cameras, or actuators.

This dual-function design makes Optoelectronic Composite Cables ideal for complex environments where both communication and power distribution must coexist efficiently — a common requirement in industrial automation, surveillance, and energy management systems.

2. The Growing Importance of Reliable Communication in Industry

Industrial facilities — from manufacturing plants to energy substations — rely on uninterrupted data exchange to monitor processes, control machinery, and ensure worker safety. In these environments, communication networks must withstand vibration, temperature variations, humidity, and electromagnetic noise.

Traditional copper-based communication systems often struggle with such conditions. Signal degradation, EMI, and limited bandwidth can disrupt real-time data transmission, leading to system downtime or inaccurate readings. In contrast, Optoelectronic Composite Cables mitigate these issues by leveraging the resilience and high-speed performance of optical fibers while still providing localized power through electrical conductors.

Reliability is not merely a technical requirement; it directly impacts productivity, safety, and cost efficiency. Thus, many industries are turning to hybrid cable systems that deliver both robustness and simplicity — exactly what Optoelectronic Composite Cables are designed to provide.

3. Structural Design Features That Promote Reliability

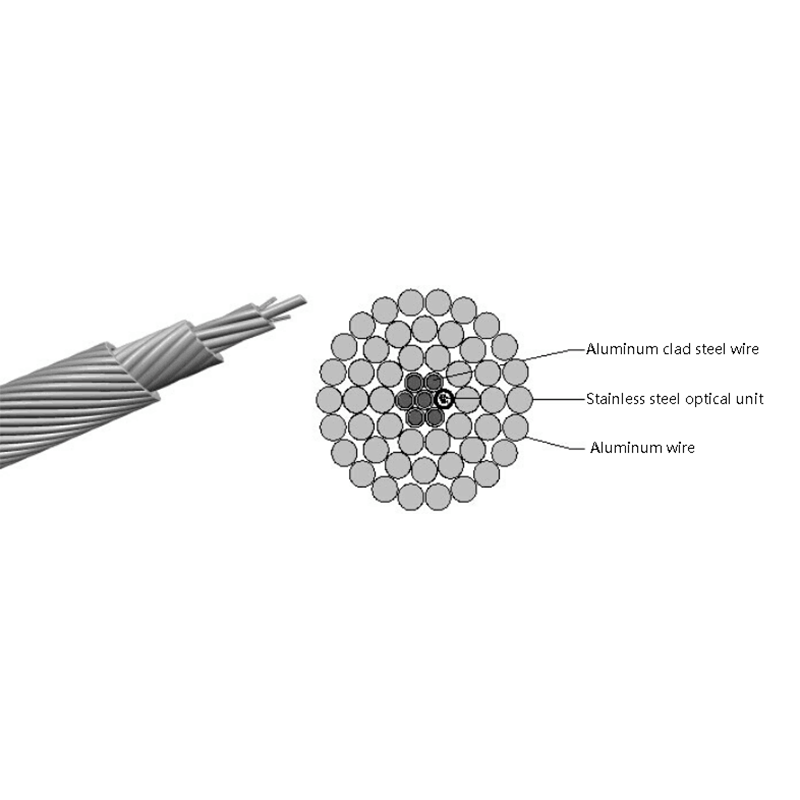

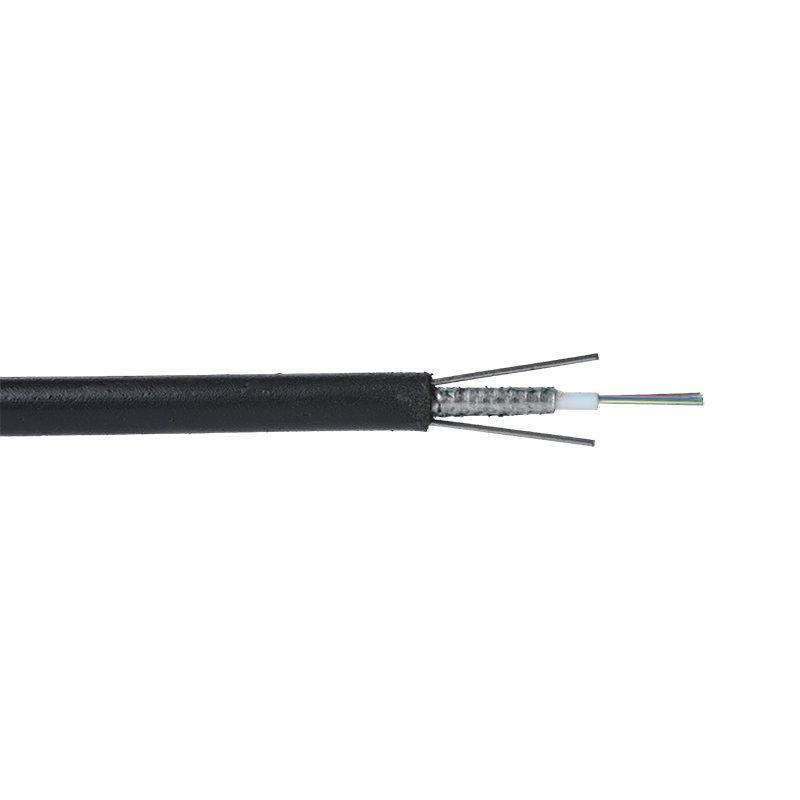

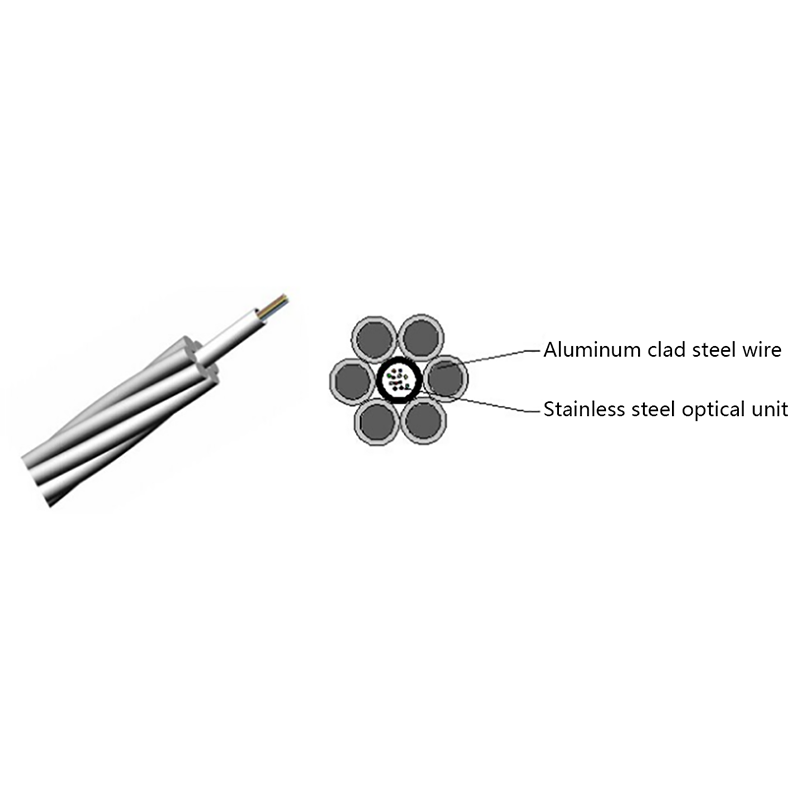

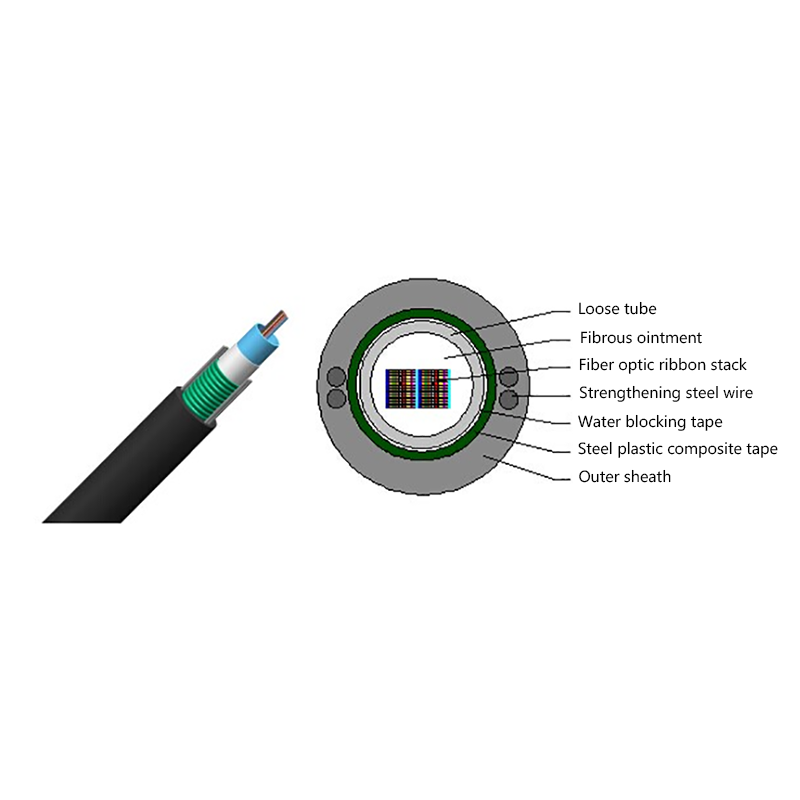

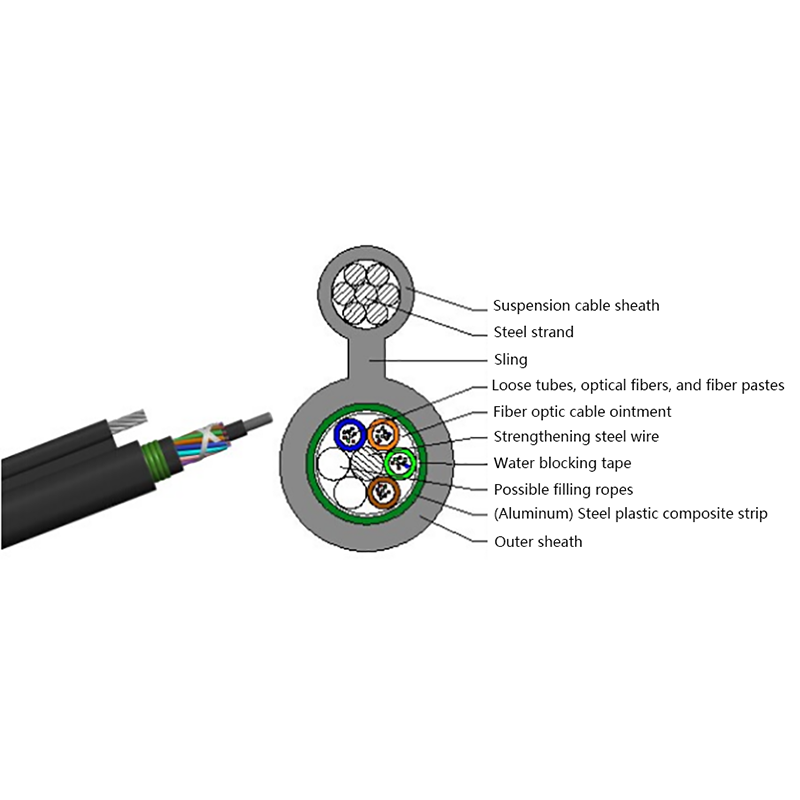

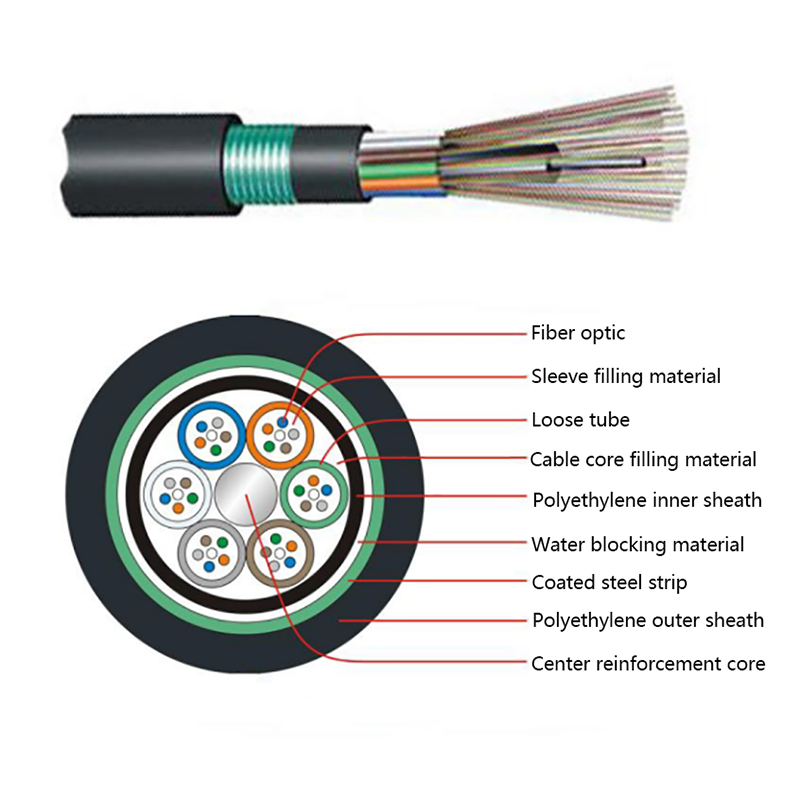

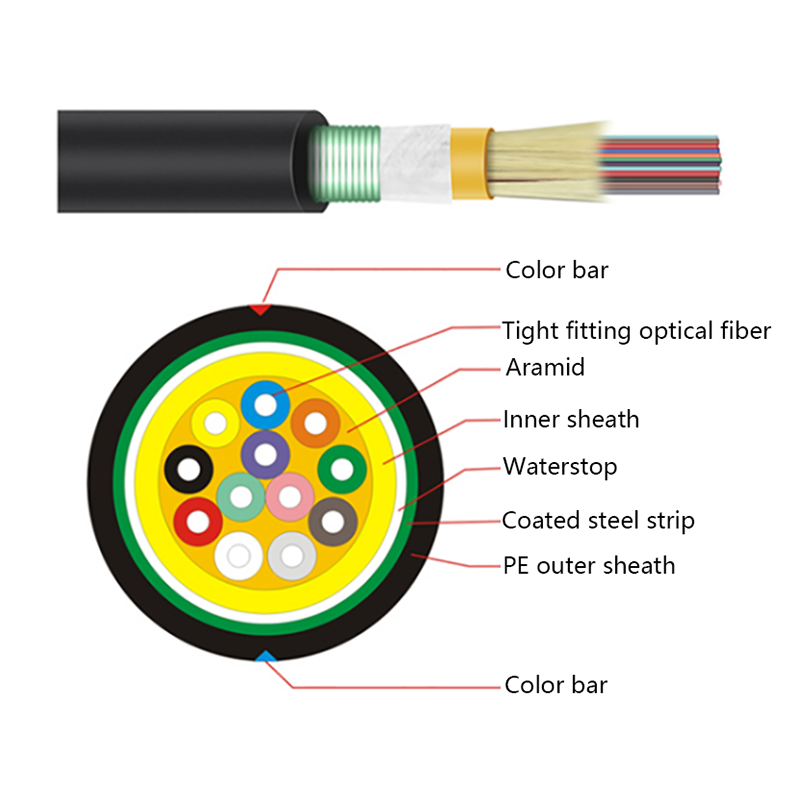

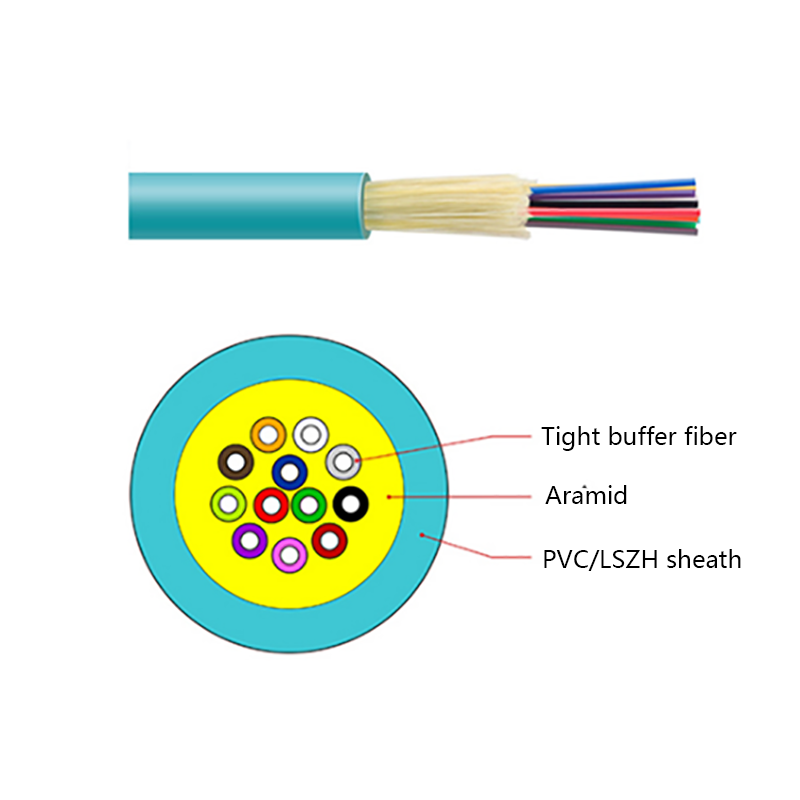

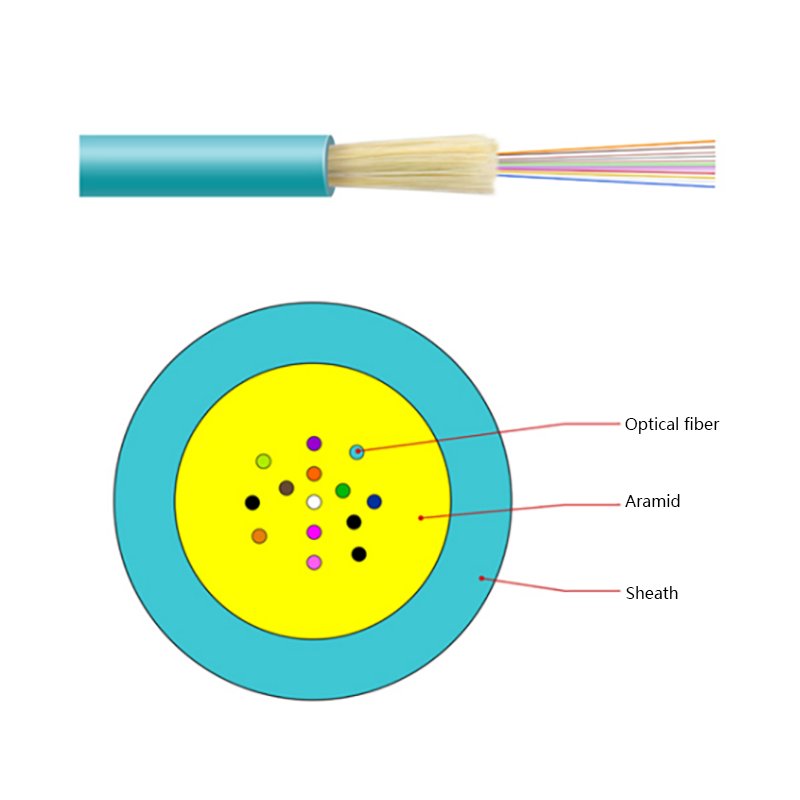

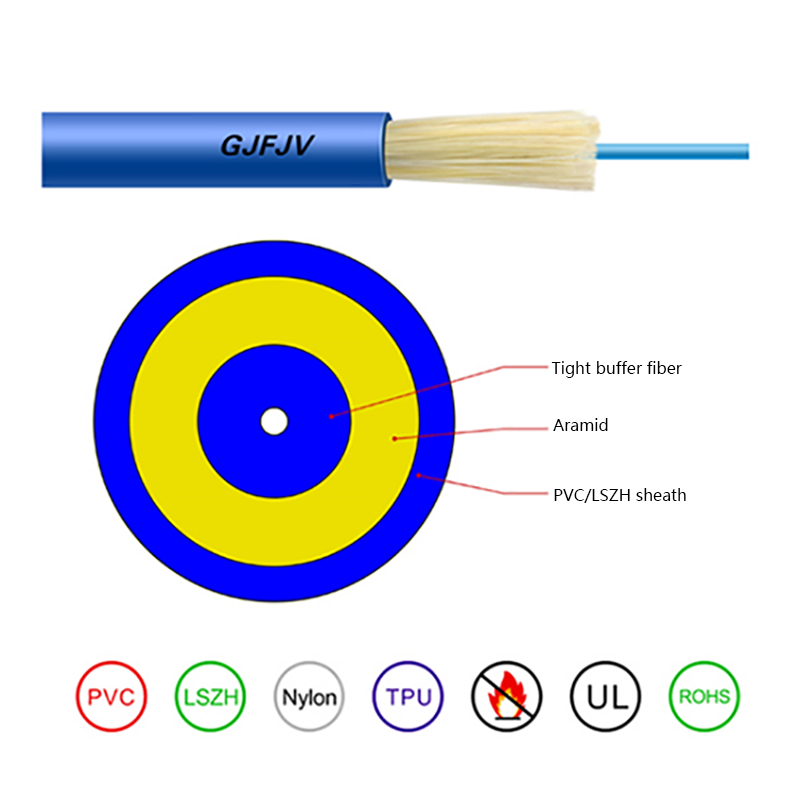

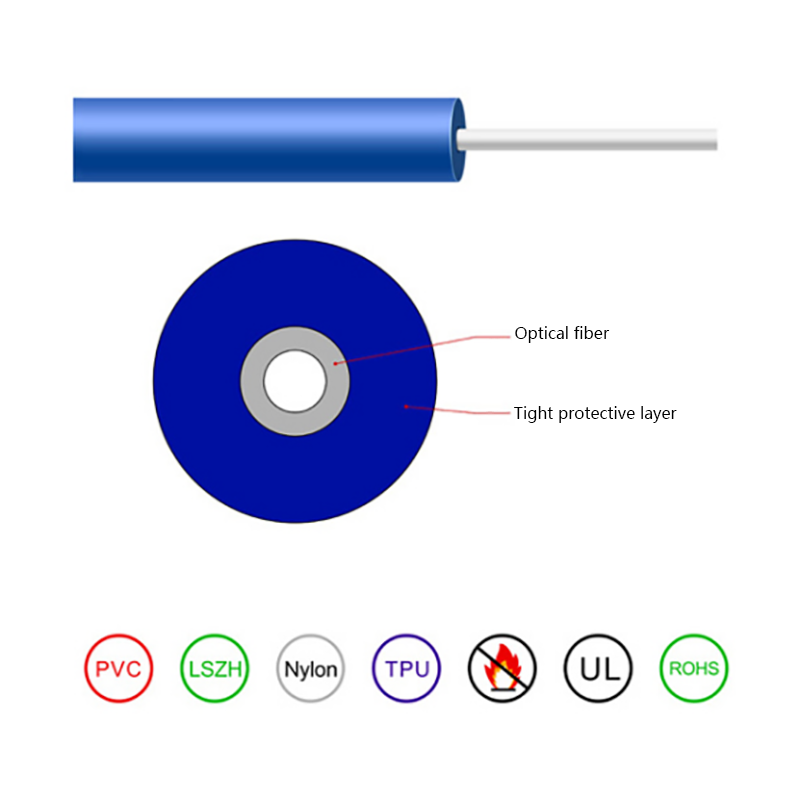

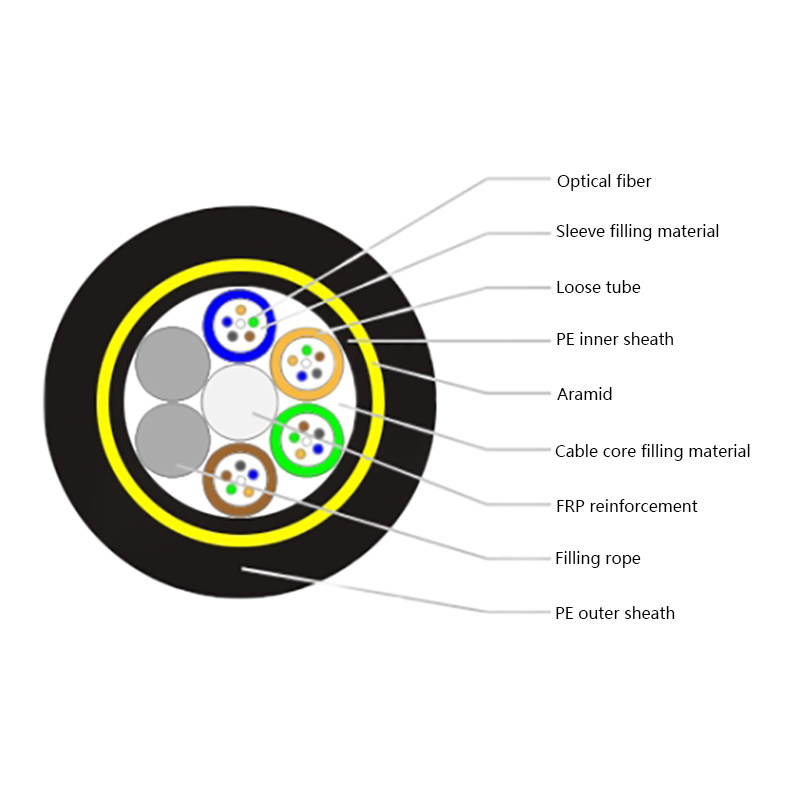

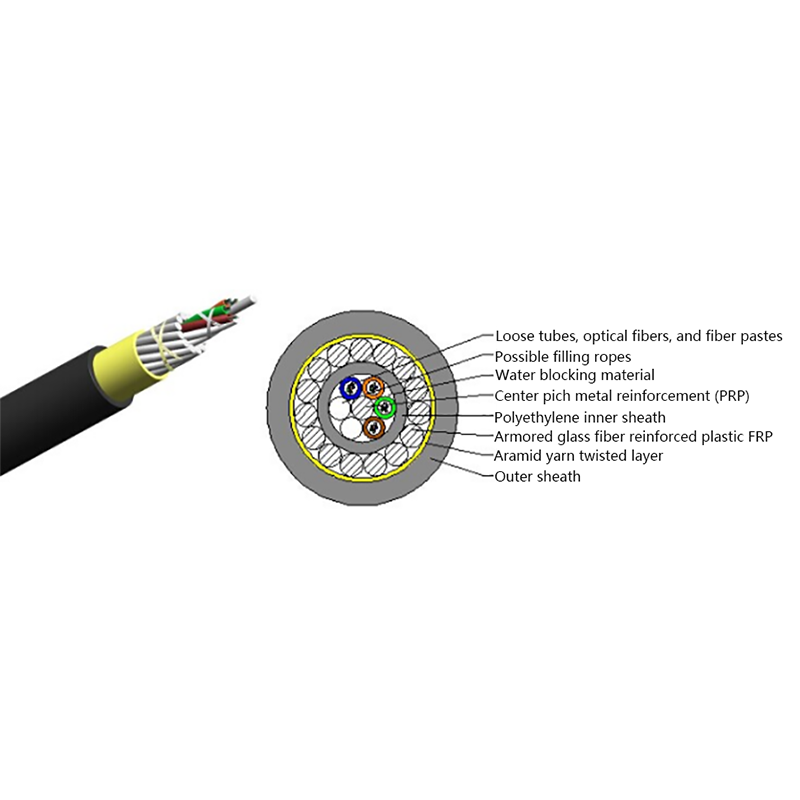

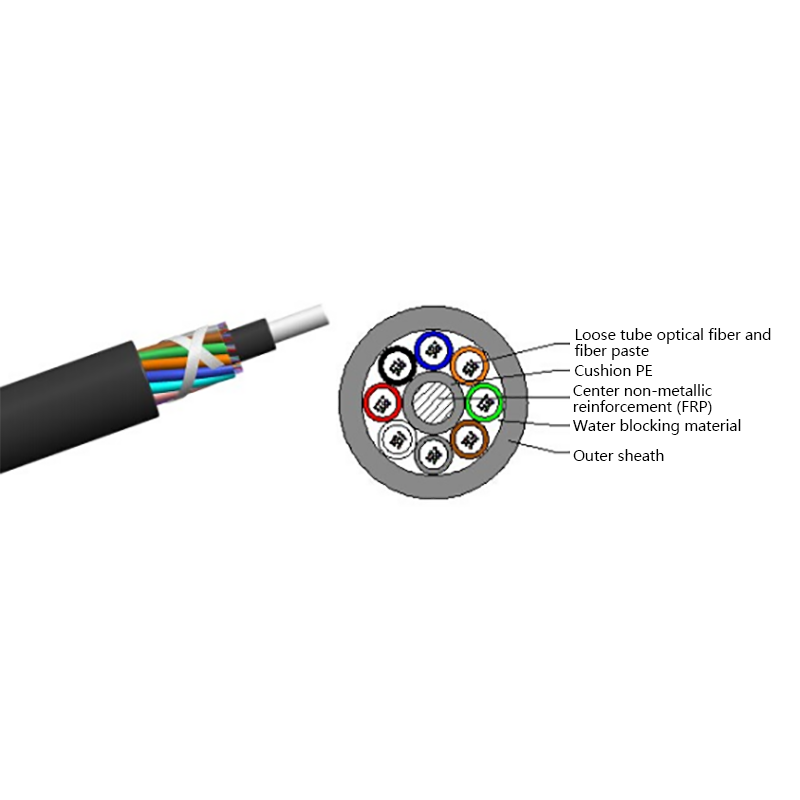

The performance of Optoelectronic Composite Cables is rooted in their advanced structural design. A typical cable includes:

- Optical Fiber Core: Transmits high-speed data with minimal attenuation over long distances.

- Electrical Conductors: Carry power or control signals to devices that cannot rely solely on fiber optics.

- Reinforcement Layers: Protect the fibers and wires from mechanical stress, vibration, and bending.

- Sheath and Insulation: Shield the cable from moisture, chemicals, UV exposure, and physical abrasion.

- EMI Shielding (if required): Provides additional protection in environments with strong electromagnetic fields.

By integrating these components into a single, compact unit, Optoelectronic Composite Cables minimize the number of separate wiring systems required. Fewer connections and joints reduce potential failure points — a critical factor in maintaining communication reliability.

4. Immunity to Electromagnetic Interference (EMI)

One of the most significant challenges in industrial communication is electromagnetic interference. Motors, welding equipment, high-voltage lines, and switching devices all produce electromagnetic fields that can disrupt electrical signals in traditional copper cables.

Optical fibers, however, transmit data using light, making them inherently immune to EMI. In Optoelectronic Composite Cables, the optical portion ensures that critical data communication remains stable and error-free, even in environments with intense electrical noise.

This characteristic is particularly valuable in heavy industries such as manufacturing, mining, and power generation, where high electromagnetic activity is unavoidable. With EMI immunity, these cables provide a secure channel for transmitting control commands, sensor readings, and operational data without distortion.

5. Simplified Installation and Reduced System Complexity

Another major way Optoelectronic Composite Cables enhance reliability is through system simplification. Traditionally, separate cables are used for power and data. This not only increases installation time and labor costs but also introduces more connectors and junctions that can fail over time.

With Optoelectronic Composite Cables, both functions are combined in one cable. The result is:

- Fewer cable runs and connectors.

- Reduced space requirements in conduits and trays.

- Simplified maintenance and troubleshooting.

- Lower overall system weight and complexity.

By streamlining the infrastructure, the risk of connection errors and physical wear decreases. This integrated design contributes directly to long-term reliability, especially in industrial systems where downtime can be costly.

6. Enhanced Mechanical Strength and Environmental Resistance

Industrial environments often expose communication cables to harsh conditions such as vibration, bending, high temperatures, and exposure to oils or chemicals. Optoelectronic Composite Cables are engineered with durable materials and mechanical reinforcements to endure these stresses.

The outer sheathing is typically made of materials resistant to abrasion, UV light, and chemicals, while the internal structure may include aramid yarn or steel strength members for added tensile strength. Some variants also feature waterproofing or flame-retardant properties, depending on the installation environment.

Because of this rugged construction, Optoelectronic Composite Cables maintain consistent performance even in difficult conditions. Their resilience reduces the risk of cable damage and data interruption, ensuring that communication networks remain operational and dependable over time.

7. Support for Power and Data Transmission Over Long Distances

In many industrial facilities, equipment such as remote sensors, surveillance cameras, or control panels are located far from central control rooms. Providing both power and communication over long distances can be challenging.

Optoelectronic Composite Cables solve this issue by combining low-loss optical fibers with high-efficiency conductors. The optical fibers can transmit data signals over kilometers without degradation, while the copper conductors can supply low-voltage power to connected devices.

This dual-function capability is especially useful in environments such as:

- Oil and gas fields

- Wind or solar farms

- Remote monitoring stations

- Factory automation systems

By ensuring stable communication and power delivery even across long distances, these cables help maintain operational reliability in dispersed or large-scale installations.

8. Flexibility and Compatibility with Modern Industrial Networks

Modern industrial communication relies on a variety of network standards — including Ethernet, Modbus, PROFIBUS, and industrial IoT protocols. Optoelectronic Composite Cables are designed to integrate seamlessly with these systems, supporting high-speed data rates required for real-time monitoring and automation.

Their compatibility allows engineers to replace multiple cable types with a single, unified solution, simplifying both design and maintenance. This flexibility makes them suitable for both retrofits and new installations.

In smart factories and Industry 4.0 environments, where sensors, robots, and control units must communicate continuously, Optoelectronic Composite Cables serve as the backbone of reliable, low-latency data exchange.

9. Improved Safety and Reduced Downtime

Safety and uptime are critical metrics in industrial operations. Faulty communication lines can lead to delayed sensor feedback, incorrect control signals, or equipment malfunctions — all of which may pose risks to workers and machinery.

Optoelectronic Composite Cables mitigate these risks by ensuring stable data transmission and dependable power delivery. The optical component prevents interference-related malfunctions, while the rugged cable design minimizes mechanical failures.

Moreover, because these cables simplify the cabling architecture, they are easier to inspect and maintain. Faster troubleshooting reduces downtime and enhances overall system availability — a major contributor to operational safety and productivity.

10. Energy Efficiency and Cost Effectiveness Over Time

While Optoelectronic Composite Cables may have a higher initial cost than conventional cables, their long-term benefits often outweigh the expense. Their integrated design reduces the number of cables, connectors, and installation materials needed, which can lower overall project costs.

Additionally, reduced signal loss and interference mean that less power is required for signal boosting or retransmission. Over time, this translates to energy savings and lower maintenance costs.

The combination of durability, reliability, and energy efficiency makes Optoelectronic Composite Cables a cost-effective investment for industrial facilities seeking long-term stability and reduced operational overhead.

11. Applications Across Industrial Sectors

Optoelectronic Composite Cables are used across a broad range of industrial sectors, including:

- Manufacturing: For robotics, automated production lines, and data acquisition systems.

- Energy: In wind farms, substations, and solar installations where remote sensors need both data and power.

- Transportation: In railway signaling, airport monitoring, and traffic control systems.

- Security: For surveillance cameras and access control systems that require combined data and power connections.

- Oil and Gas: For offshore platforms and drilling sites requiring robust, long-distance communication.

In each of these sectors, reliability is paramount — and the unique hybrid structure of Optoelectronic Composite Cables helps ensure consistent performance under demanding conditions.

12. The Future of Optoelectronic Composite Cables in Industry

As industries continue to evolve toward more automated, connected, and data-driven operations, the need for resilient communication infrastructure will only grow.

Emerging technologies such as industrial IoT, AI-driven control systems, and edge computing rely on rapid, uninterrupted data flow. Optoelectronic Composite Cables are poised to play an increasingly important role in supporting these technologies by delivering both high-speed communication and reliable power in one solution.

Future innovations may include lighter materials, higher fiber counts, and even smarter cable designs with built-in monitoring capabilities to predict and prevent failures before they occur.

13. Conclusion

In today’s industrial landscape, communication reliability is as critical as the machinery itself. Optoelectronic Composite Cables offer a comprehensive solution by merging optical and electrical functionalities into a single, durable system.

They resist electromagnetic interference, reduce system complexity, extend communication distances, and maintain robust performance in harsh environments. Beyond technical advantages, these cables also contribute to operational safety, cost efficiency, and long-term sustainability.

For industries seeking dependable and efficient communication infrastructure, Optoelectronic Composite Cables represent a forward-looking investment — one that enhances reliability today and prepares systems for the connected technologies of tomorrow.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体