How Does the Performance of Air Blown Micro Cables Compare to Traditional Fiber Optic Cables?

Fiber optic technology has revolutionized the way we transmit data, offering unprecedented bandwidth and reliability. Within this field, Air Blown Micro Cables (ABMCs) have emerged as a flexible and cost-effective solution, particularly suited for modern networks requiring scalability and high fiber density. But how does their performance truly compare to traditional fiber optic cables?

Understanding Air Blown Micro Cables

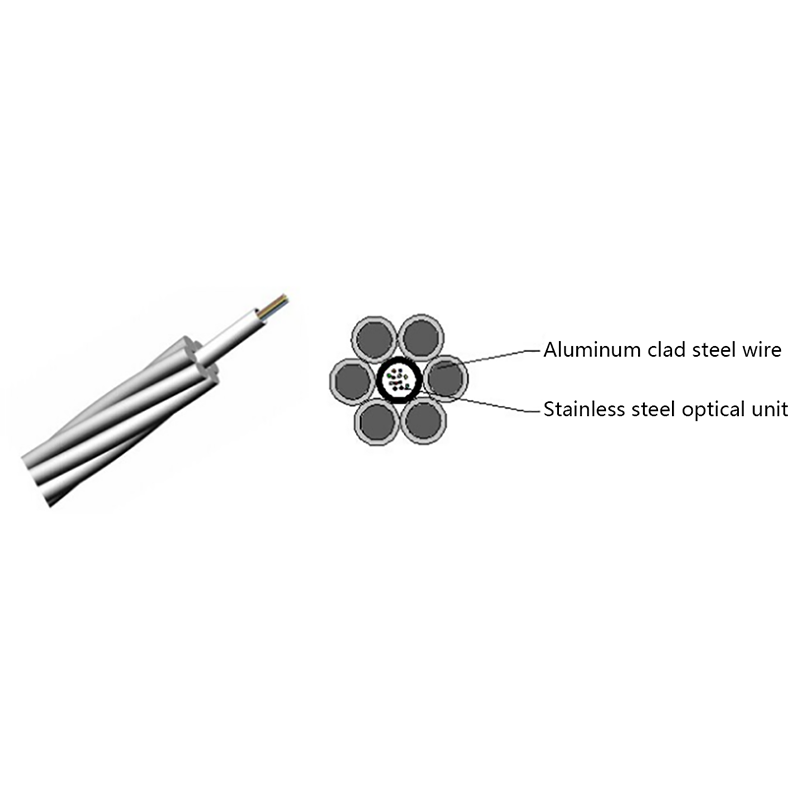

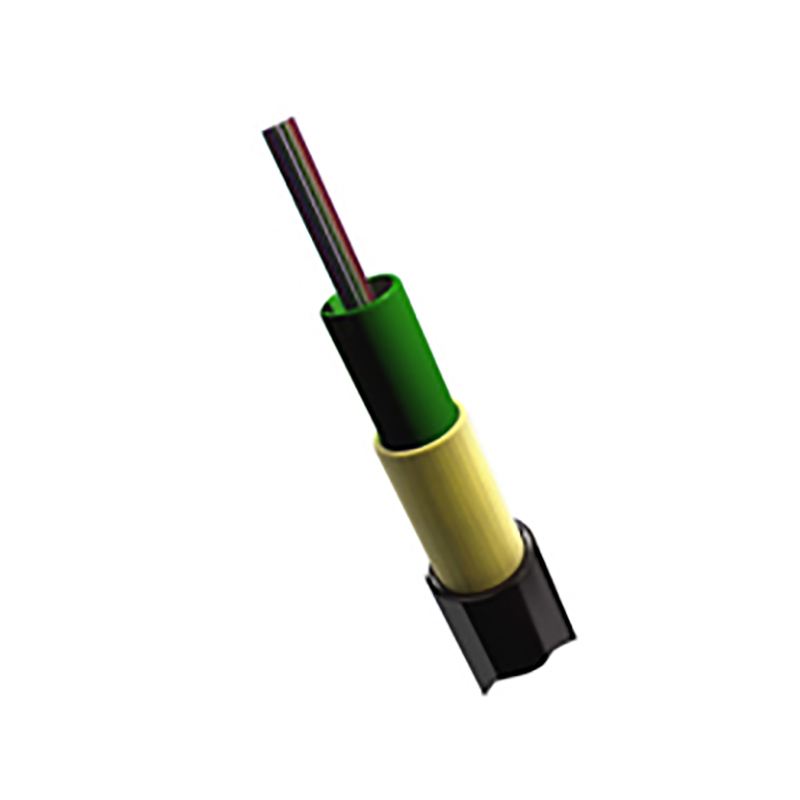

Air Blown Micro Cables are a type of optical fiber cable specifically designed for installation using compressed air. Unlike conventional fiber optic cables, ABMCs are lightweight, flexible, and modular, allowing operators to blow fibers into pre-installed ducts as needed. This technology decouples cable deployment from fiber count, enabling networks to expand or reconfigure without significant civil works.

Key Features of ABMCs:

- Micro-diameter design: Typically ranging from 2 mm to 6 mm in outer diameter.

- Blowable installation: Fibers are introduced into ducts using controlled airflow.

- Modularity: Additional fibers can be added without replacing existing cables.

- High fiber density: Hundreds of fibers can be installed in a single duct.

Technical Comparison with Traditional Fiber Optic Cables

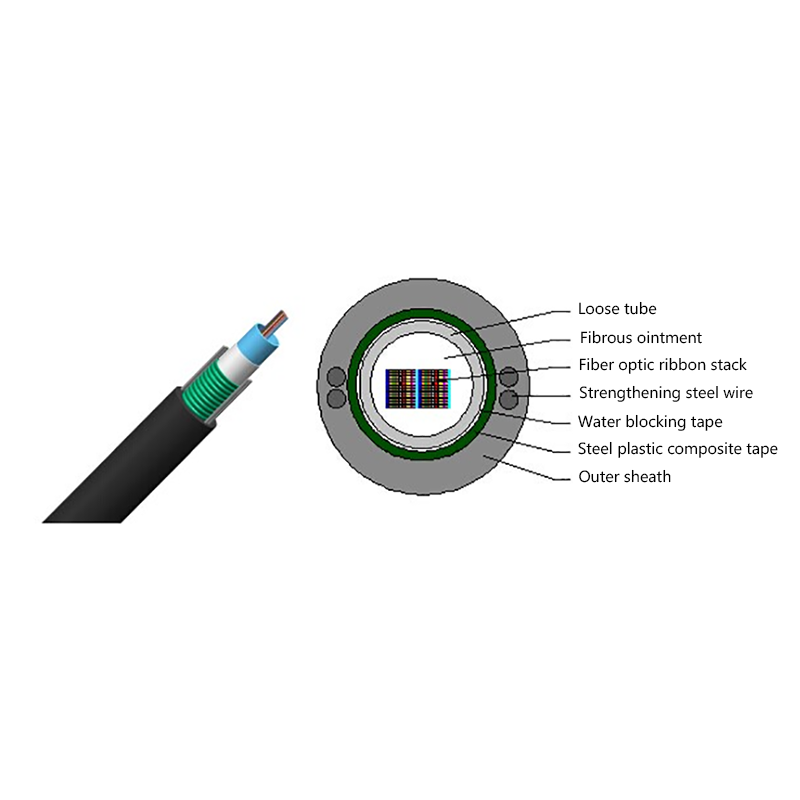

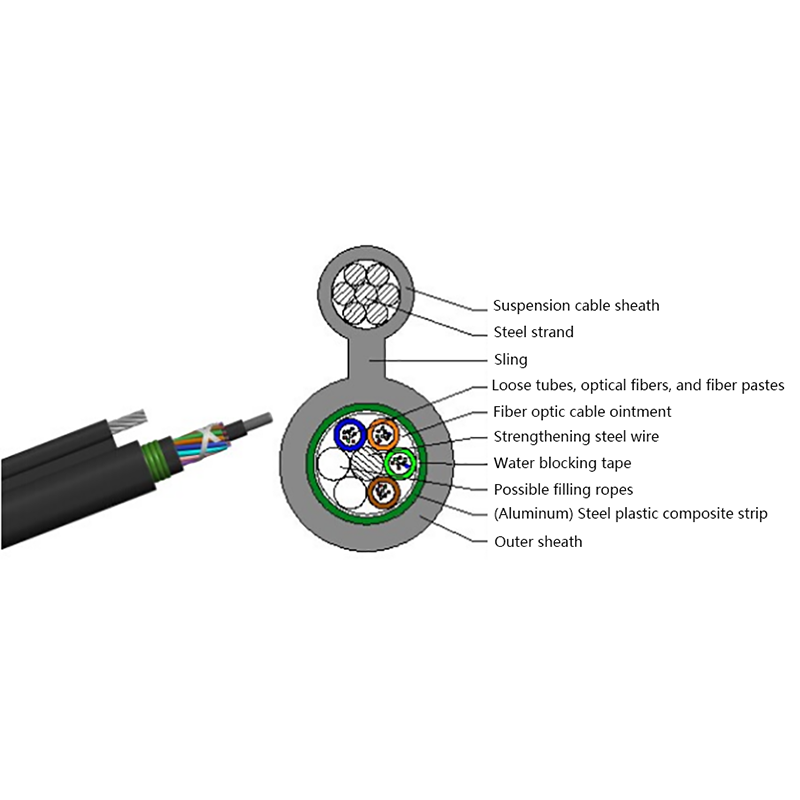

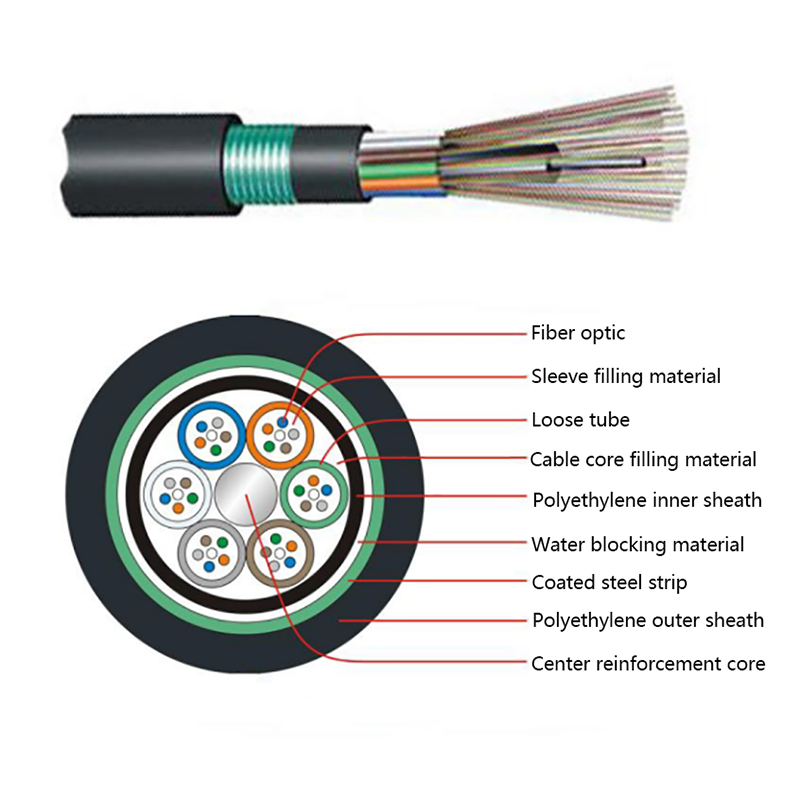

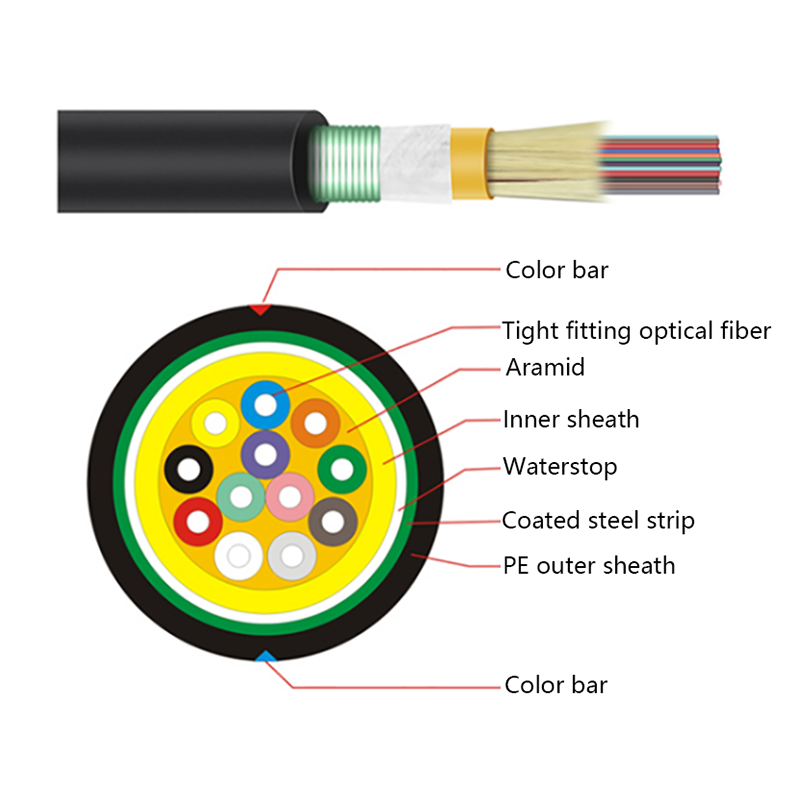

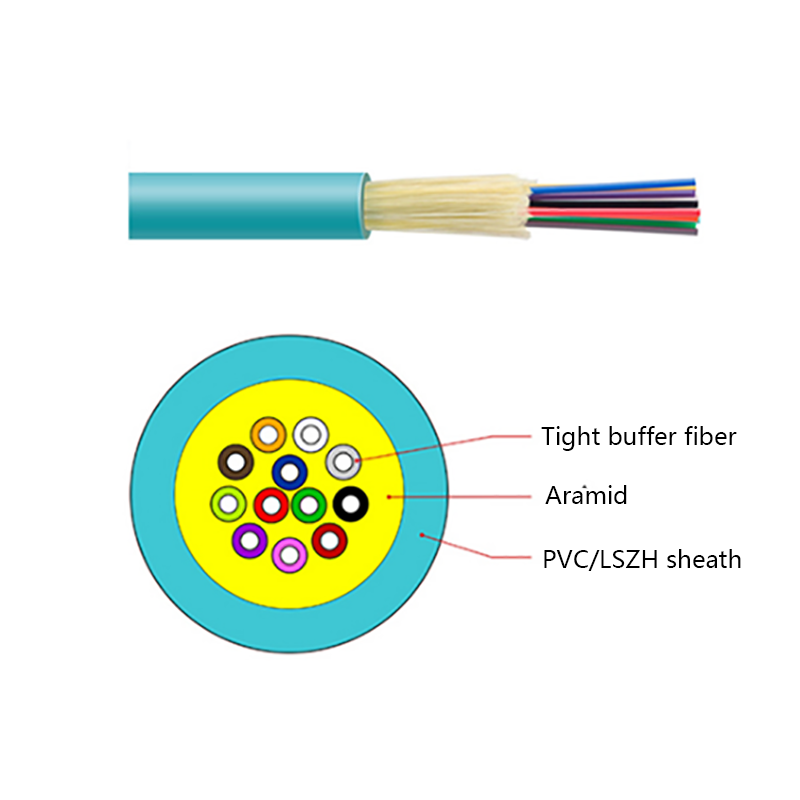

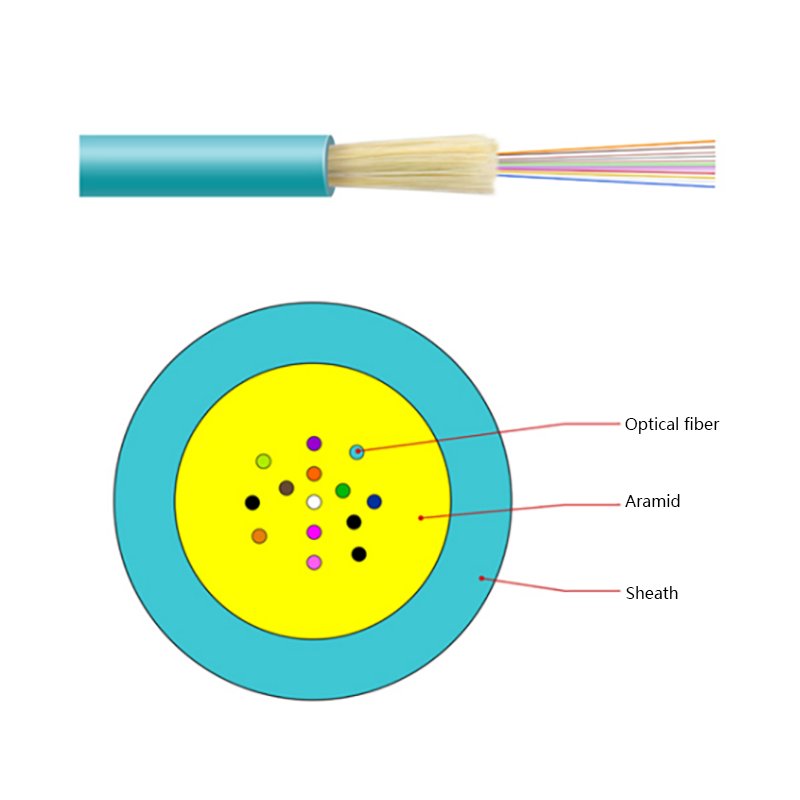

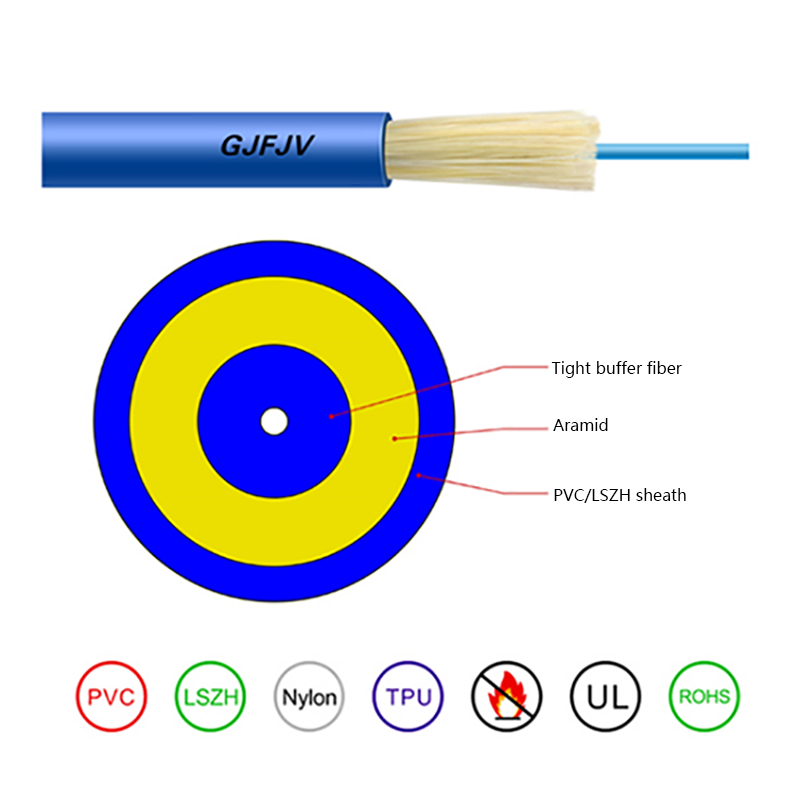

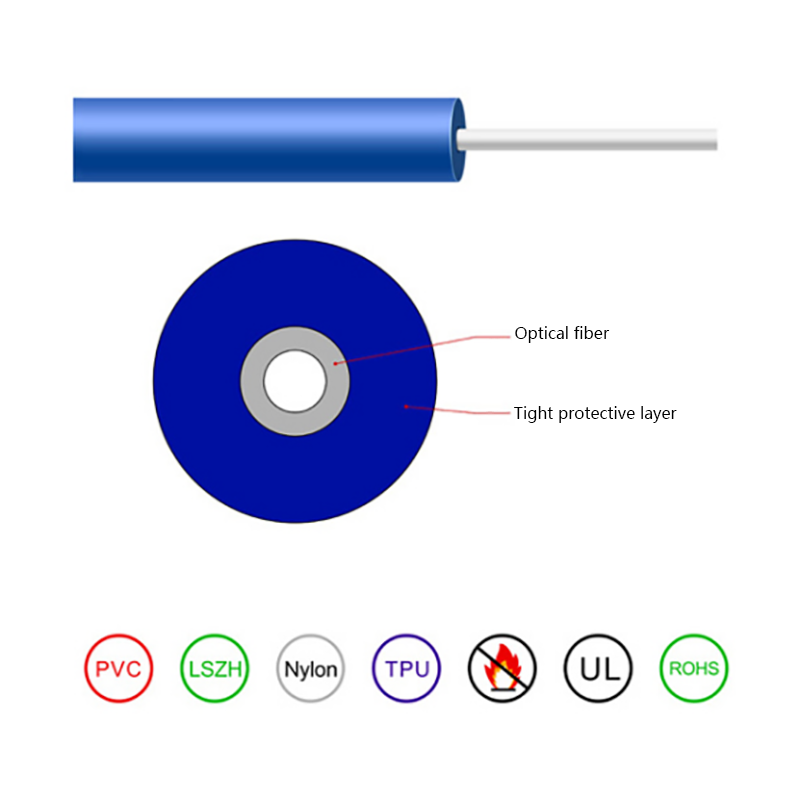

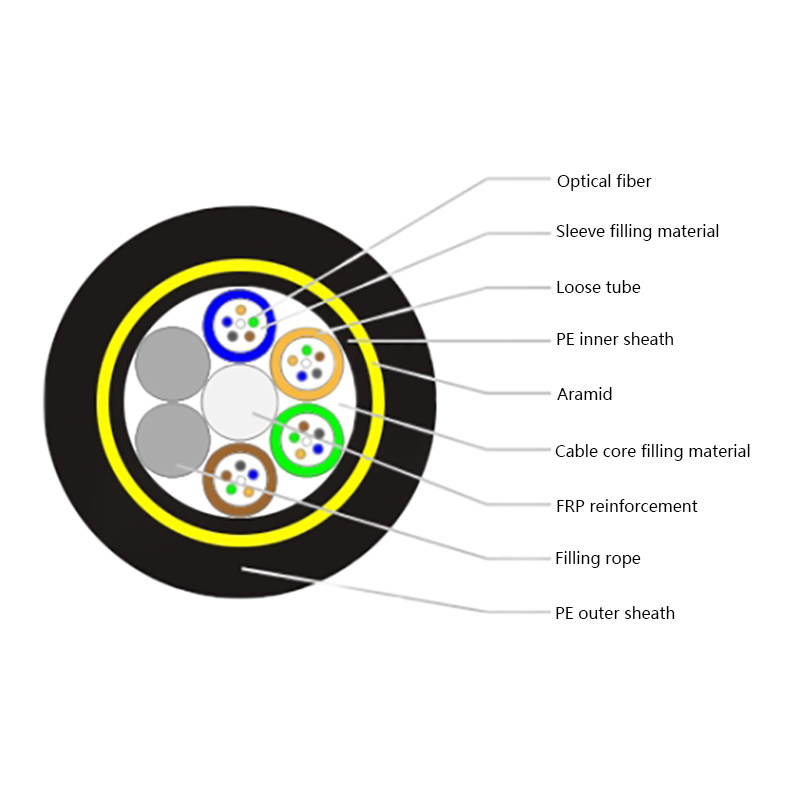

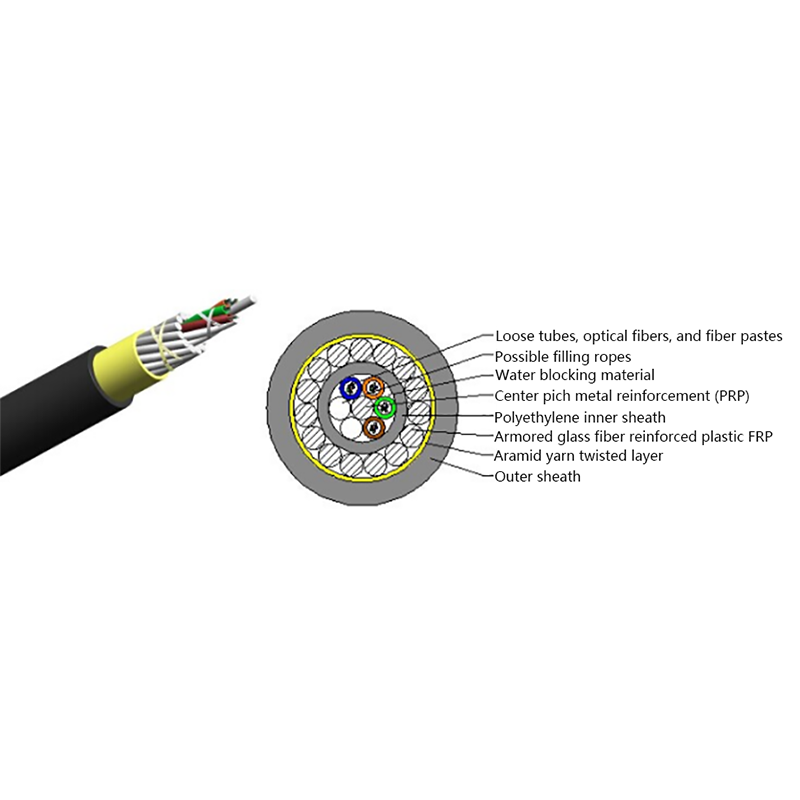

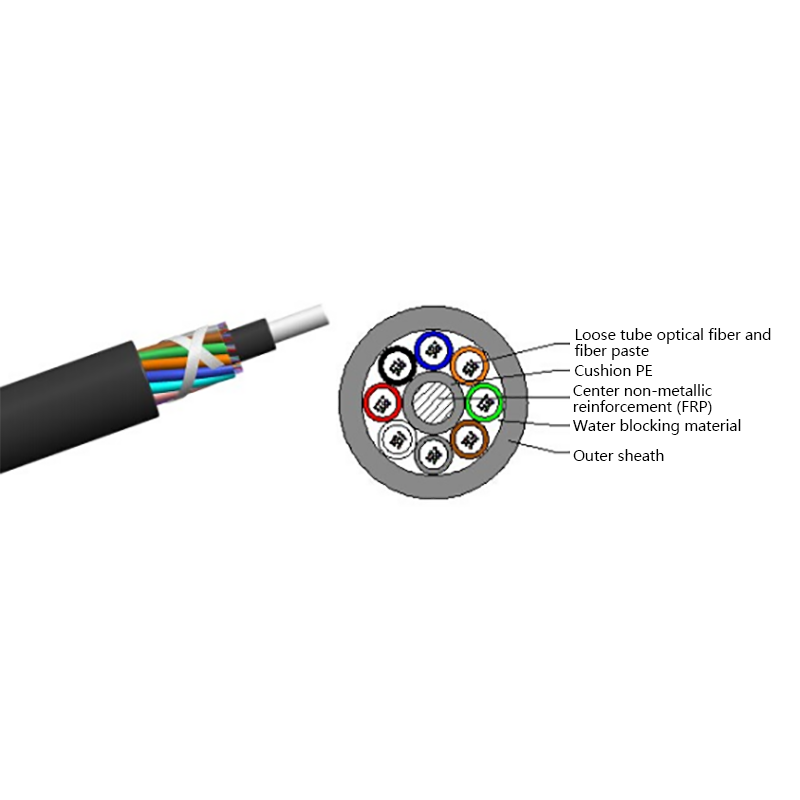

Cable Construction and Design

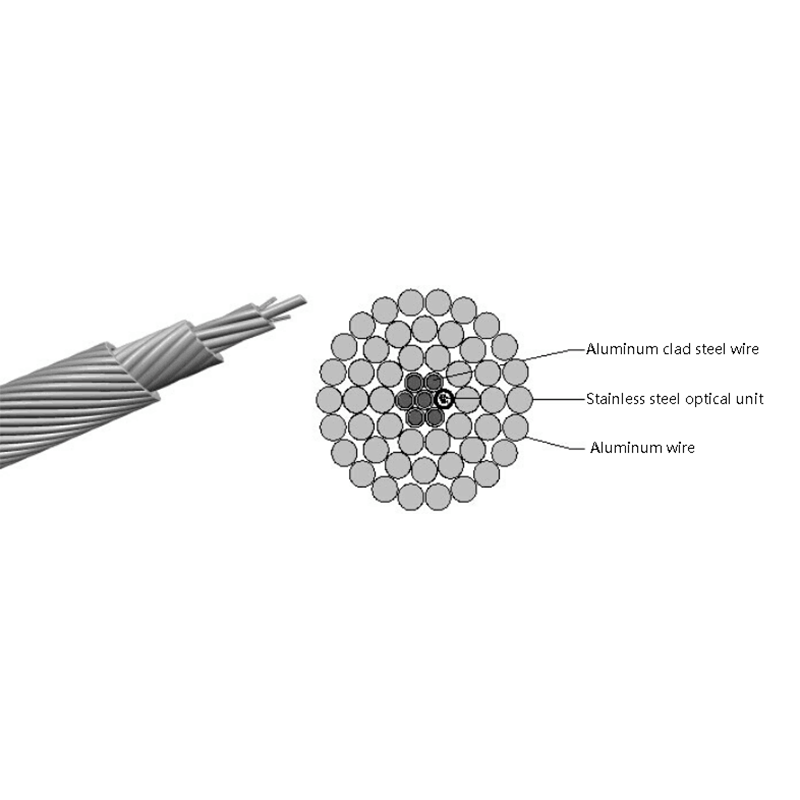

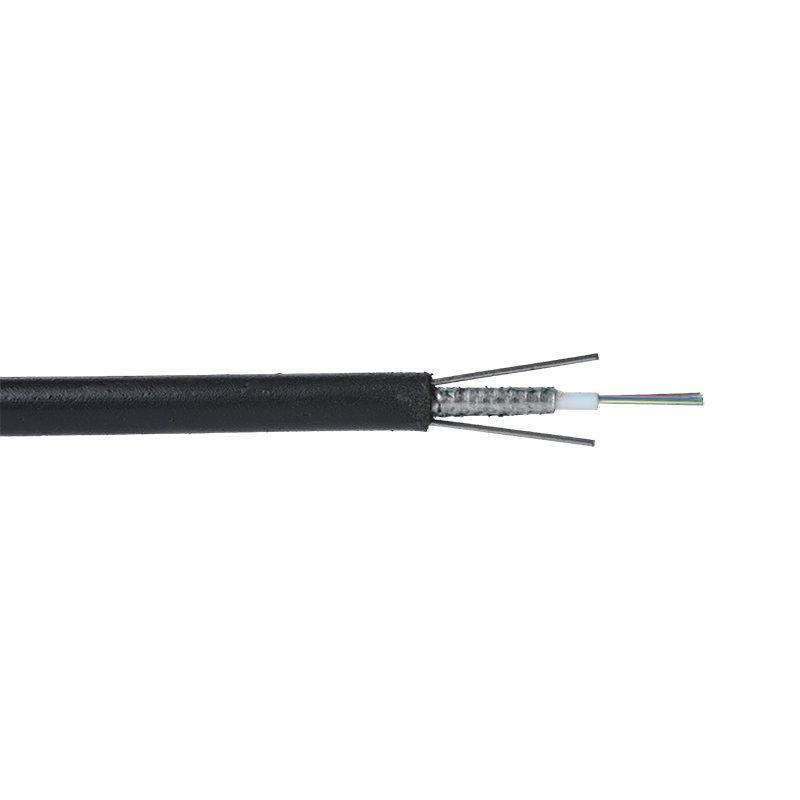

Traditional fiber optic cables are often built with tight-buffered or loose-tube designs, which combine multiple fibers in a single sheath, sometimes reinforced with steel wires for tensile strength. ABMCs, in contrast, focus on minimizing weight and friction, using micro-tubes or loose bundles of fibers encased in a lightweight sheath.

Implications:

- ABMCs are easier to install in existing ducts and complex urban environments.

- Traditional cables offer more mechanical robustness, suitable for direct burial or aerial deployment.

Fiber Count and Scalability

Conventional cables are limited by their initial fiber count. Expanding the network often requires pulling additional cables or creating new ducts. ABMCs, however, allow operators to blow new fibers into existing micro-ducts, providing incremental scalability.

Performance Impact:

- ABMCs reduce upfront infrastructure costs while supporting future bandwidth growth.

- Traditional cables may deliver higher initial fiber density but are less flexible for upgrades.

Bandwidth and Signal Performance

Both ABMCs and traditional fiber optic cables use similar fiber types, including single-mode (SMF) and multimode fibers (MMF). As a result, signal loss, attenuation, and bandwidth performance are largely determined by the fiber itself rather than the cable type.

Key Differences:

- ABMCs may have slightly higher micro-bend sensitivity due to smaller cable diameters, requiring careful handling during installation.

- Proper installation ensures that ABMCs achieve comparable attenuation (typically 0.35 dB/km for SMF at 1310 nm) and high-speed data transmission performance.

Installation Advantages

Air Blown Deployment

One of the most notable benefits of ABMCs is the air-blown installation method. Using compressed air, micro cables can be deployed over long distances without the need for heavy pulling forces, reducing the risk of fiber damage.

Advantages over traditional cables:

- Minimizes duct congestion and friction.

- Reduces installation time and labor costs.

- Allows for post-installation fiber addition, which is impossible with conventional cables.

Adaptability to Existing Infrastructure

ABMCs excel in retrofit projects, particularly in urban or campus networks where installing new ducts is costly. The flexibility of blowing cables into existing ducts reduces civil engineering costs and avoids disruption.

Maintenance and Network Upgrades

Traditional fiber optic cables often require splicing or pulling new cables for network expansion, which can be time-consuming and disruptive. ABMCs, by contrast, allow incremental upgrades, enabling operators to add new fibers as demand grows.

Benefits of ABMCs for maintenance:

- Faster repairs: Faulty fibers can be replaced individually without disturbing others.

- Future-proof networks: Easily accommodates higher bandwidth demands without large-scale construction.

- Reduced downtime: Expansion or reconfiguration can be done with minimal service interruption.

Environmental and Mechanical Considerations

While ABMCs offer flexibility, traditional fiber optic cables provide greater mechanical protection for harsh environments. Direct burial cables, for instance, can withstand extreme temperatures, moisture, and rodent attacks. ABMCs rely on duct protection and careful installation practices to maintain reliability.

Trade-offs:

- ABMCs are ideal for urban, indoor, or ducted outdoor environments.

- Traditional cables are preferable for aerial, direct-burial, or exposed installations.

Cost Implications

From a total cost of ownership perspective, ABMCs can offer significant savings, particularly in networks that require scalability or frequent upgrades. While the initial cable cost per fiber may be higher due to the micro-cable design and specialized installation equipment, the long-term flexibility and reduced civil works often justify the investment.

Comparative summary:

| Aspect | ABMC | Traditional Cable |

| Installation | Blowable, fast, minimal duct stress | Pulled, slower, may need new ducts |

| Scalability | Incremental, easy fiber addition | Limited by initial fiber count |

| Mechanical Protection | Dependent on duct | High, suitable for harsh conditions |

| Maintenance | Easier, low downtime | More complex, may disrupt service |

| Cost | Higher per unit fiber, lower total over time | Lower per unit fiber, higher upgrade cost |

Practical Use Cases

ABMCs are particularly suited for:

- Fiber-to-the-Home (FTTH) networks in urban areas

- Campus or enterprise networks requiring future expansion

- Smart city infrastructure, where ducted fiber is prevalent

Traditional fiber cables are preferred for:

- Long-haul transmission over exposed terrain

- Direct burial applications in rural or industrial environments

- Aerial or harsh climate deployments

Conclusion

Air Blown Micro Cables represent a modern evolution of fiber optic technology, combining flexibility, scalability, and operational efficiency. While traditional fiber optic cables maintain their place in environments requiring robust mechanical protection, ABMCs excel in urban deployments, network expansions, and situations where future-proofing is critical.

In terms of raw performance—bandwidth, attenuation, and signal integrity—ABMCs can match traditional cables when properly installed. However, the key differentiators lie in installation flexibility, cost-effectiveness over time, and adaptability to changing network requirements. For network planners looking to build scalable, resilient, and upgrade-friendly infrastructure, ABMCs offer a compelling alternative without compromising the core benefits of fiber optics.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体