The Primary Role: Tensile Strength and Protection

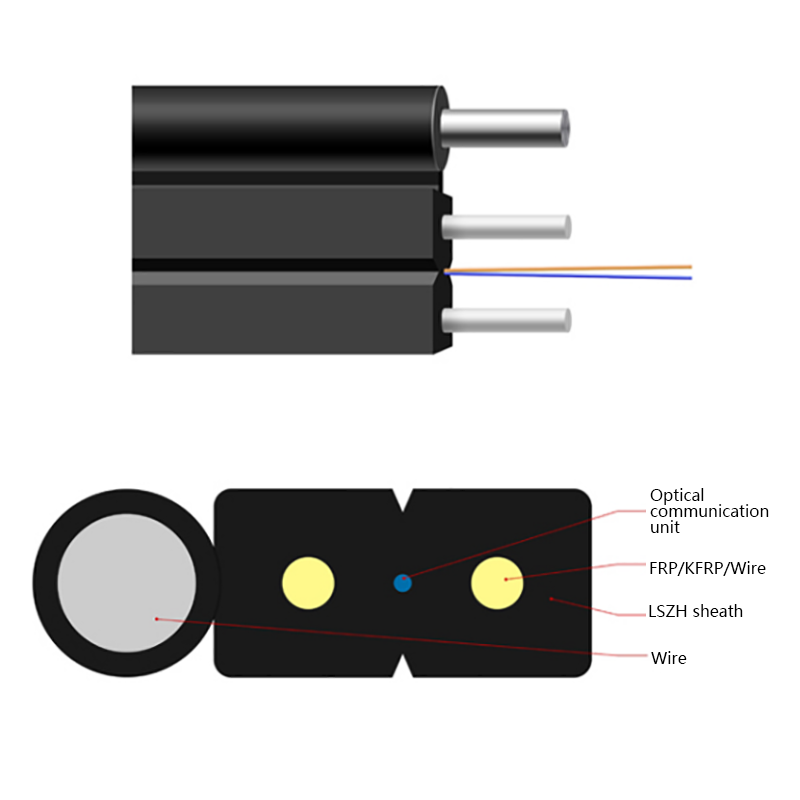

The two parallel strengthening ribs, typically made of fiberglass reinforced plastic (FRP) or steel wire, are the backbone of the FTTH Butterfly Optic Cables. Their core purpose is to absorb all tensile and mechanical stresses encountered during and after installation, shielding the fragile optical fibers within. This ensures signal integrity by preventing micro-bends or breaks in the fibers when the cable is pulled, stretched, or subjected to long-term hanging loads.

Enabling Installation and Deployment

These ribs are critical for practical installation methods. Their inherent strength allows installers to pull the cable through ducts or conduits over considerable distances. For aerial deployments, the ribs bear the weight of the cable span and resist environmental forces like wind and ice. The rigid structure also facilitates a clean, mid-span separation of the cable: the "wings" can be easily torn or cut away from the ribs, leaving a clean, protected fiber unit for termination.

Key Installation Advantages Provided

- Provides a firm grip for cable ties or staples without pinching the fiber core.

- Allows for higher pulling tension, reducing the need for multiple splice points.

- Maintains cable shape and prevents kinking during rough handling.

Material and Design Specifications

The choice of material for the ribs is a calculated decision based on application. FRP ribs offer excellent strength and are non-conductive, making them ideal for areas with lightning risk or near power lines. Steel wire ribs provide higher tensile strength for longer aerial spans but require proper grounding. The ribs are permanently bonded to the outer jacket, creating the distinctive "figure-8" or butterfly profile that gives the cable its name.

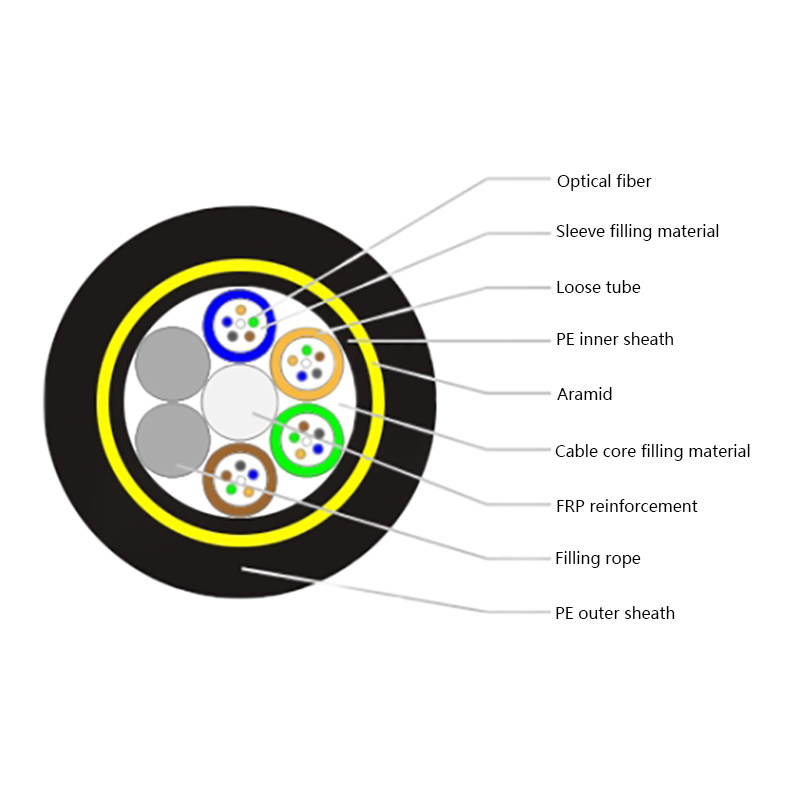

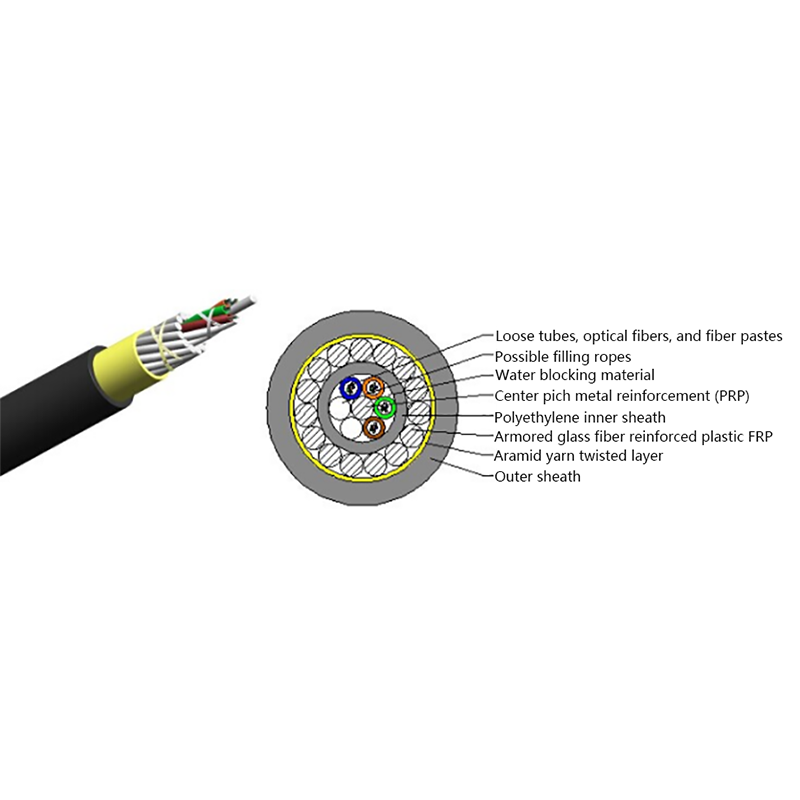

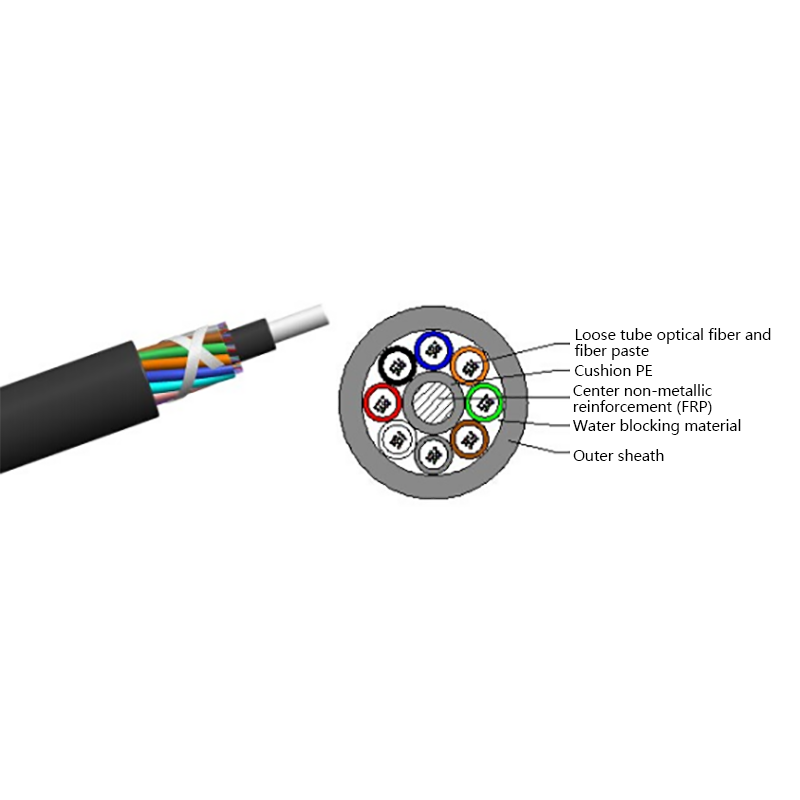

Comparative Analysis: Ribs vs. Other Strengthening

Understanding how these ribs differ from other cable designs clarifies their purpose. Unlike loose-tube cables with central strength members, the parallel ribs distribute strength laterally, creating a tear-away feature. Compared to flat drop cables with woven aramid yarn, the solid ribs provide superior crush resistance and easier mid-span access.

| Feature | Butterfly Cable with FRP Ribs | Standard Flat Drop Cable |

| Primary Strength Element | Two parallel solid FRP rods | Woven aramid yarns |

| Mid-Span Access | Clean, easy separation along ribs | Requires careful jacket stripping |

| Crush Resistance | High | Moderate |

| Preferred Installation | Aerial & Duct; Longer Pulls | Shorter Indoor/Outdoor Drops |

Impact on Long-Term Reliability

Beyond installation, the strengthening ribs ensure the cable's longevity. They prevent sagging in aerial installations, which could lead to fiber strain over time. They also protect against environmental contraction and expansion. By isolating the fibers from stress, the ribs guarantee stable optical performance and lower lifetime maintenance costs for the FTTH network.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体